A screw driven lifting platform with auxiliary lifting blocks

A technology of lifting table and screw rod, which is applied in the field of lifting table, can solve the problems that the lifting table is not easy to keep in the same position for a long time, the lifting table cannot be raised immediately, and the driving force of the screw rod increases, so as to reduce the driving power and cargo The up and down lifting table is convenient and the effect of reducing the driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

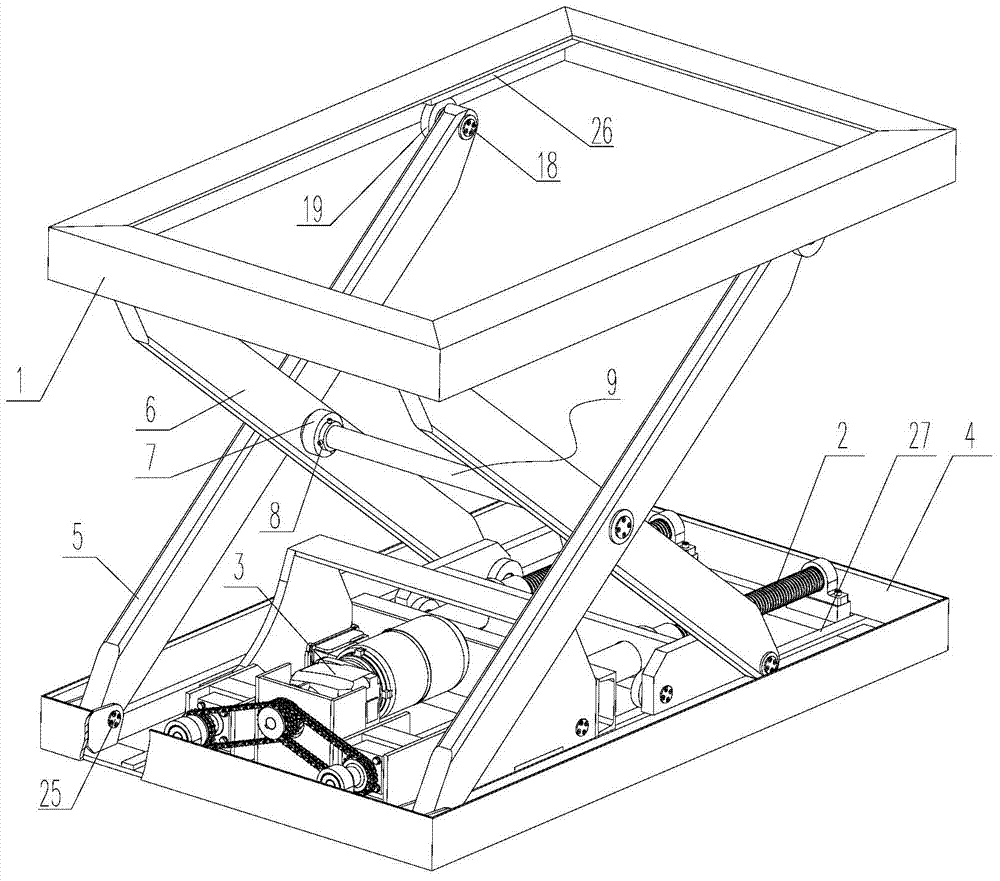

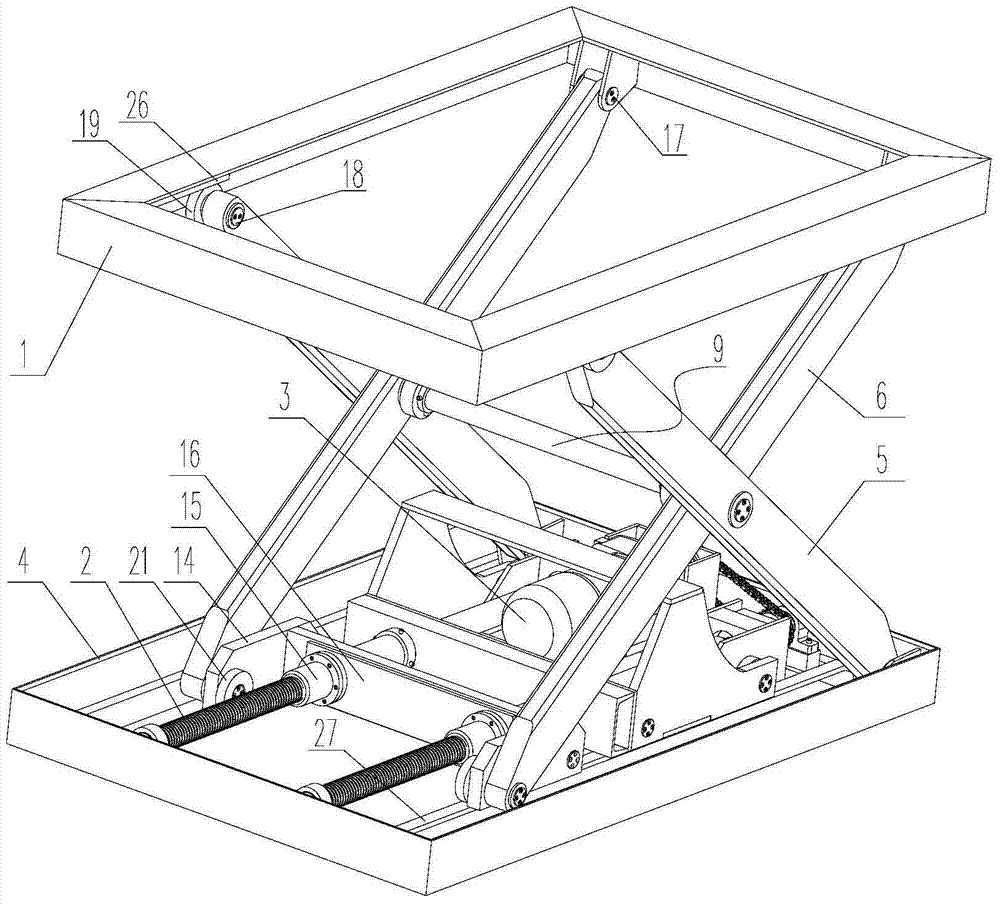

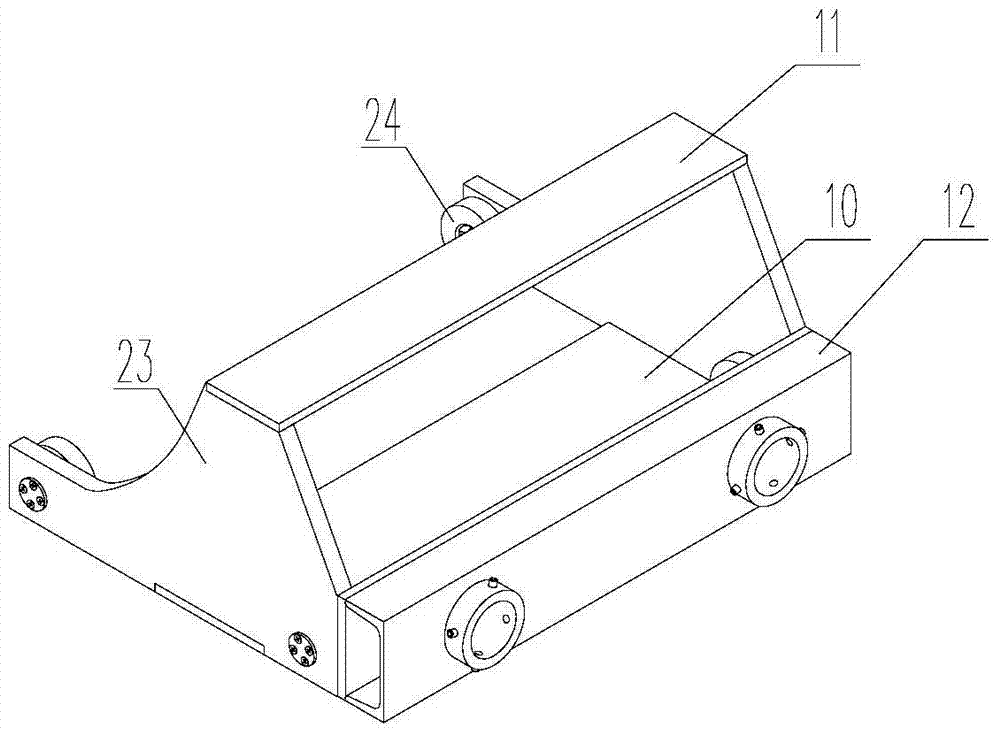

[0023] Such as figure 1 , figure 2 Shown is a screw driven lifting platform with auxiliary lifting blocks, the lifting platform includes an upper frame 1, a lower frame 4, two outer support arms 5, two inner support arms 6, two lifting plates 23, Two push rods 13, a U-shaped frame 14 and a nut connecting plate 16, the middle part of the outer support arm 5 and the inner support arm 6 are respectively hinged to form a scissor structure, and are connected together by setting a cross long axis 9. The outer support arm 5 and the inner support arm 6 are respectively arranged on the inner walls of the left and right ends of the lower frame 4 and the upper frame 1, and the lower rails 27 are respectively arranged on both sides of the lower frame 4, and the left and right sides of the lower frame 4 The wall is hinged with the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com