Steel wire rope adjusting device

A technology of adjusting device and wire rope, applied in the direction of hoisting device, transportation and packaging, spring mechanism, etc., can solve the problems of inconsistent length of wire rope, inclination, height difference of spreader, etc., to achieve the effect of safe operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

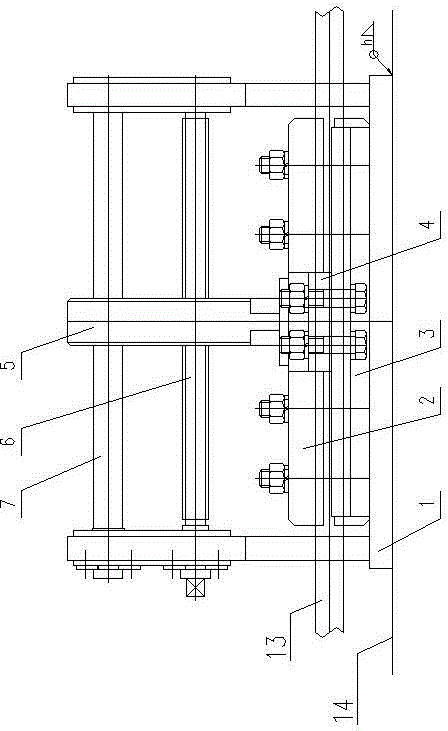

[0025] With reference to the accompanying drawings in the description, the best embodiment of the present invention is: it mainly consists of a bracket 1, a steel wire rope pressing plate 2, a chute 3, a positioning plate 4, an adjusting nut 5, an adjusting screw rod 6, a guide rod 7, a fixed wire rope bolt pair 8, Positioning bolt pair 9, nut fixing bolt pair 10 forms.

[0026] There are through holes in the middle of the vertical plates on both sides of the support 1, so that the wire rope pressing plate 2 can pass through in the assembled state.

[0027] The steel wire rope pressing plate 2 is divided into upper and lower parts, with a through rope groove in the middle, and bolt holes for pressing the steel wire rope at the upper and lower sides. The hole end of the lower pressing plate is an enlarged counterbore, which is convenient for the bolt head to sink in; the width direction of the pressing plate is There is a gap in the middle to fix the pressure plate so that it d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com