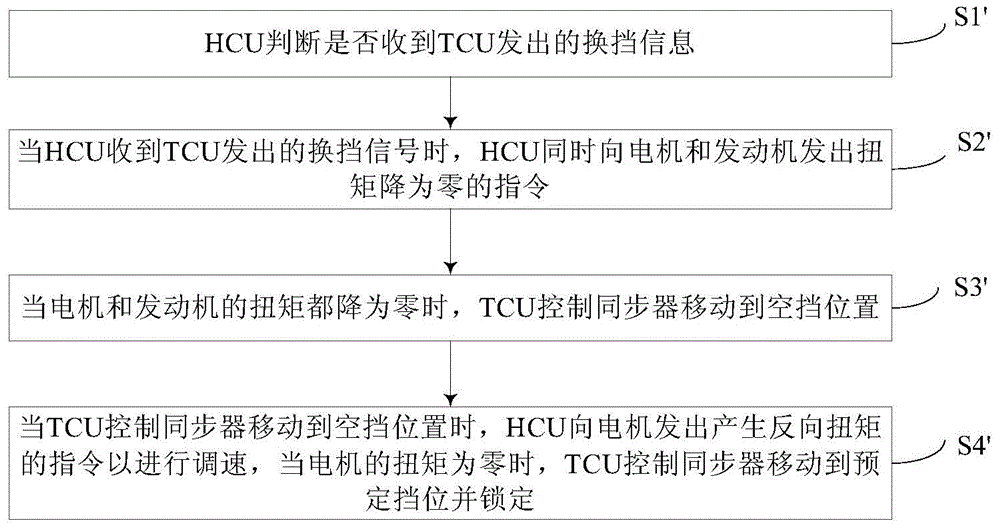

Gear-shifting control method for electric automobile and motor speed adjusting method based on gear-shifting

A technology of electric vehicles and control methods, which is applied in the field of vehicles, can solve problems such as over-regulation process and motor overshoot without specifying in detail, and achieve the effects of improving ride comfort and comfort, ensuring ride comfort, and reducing power interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

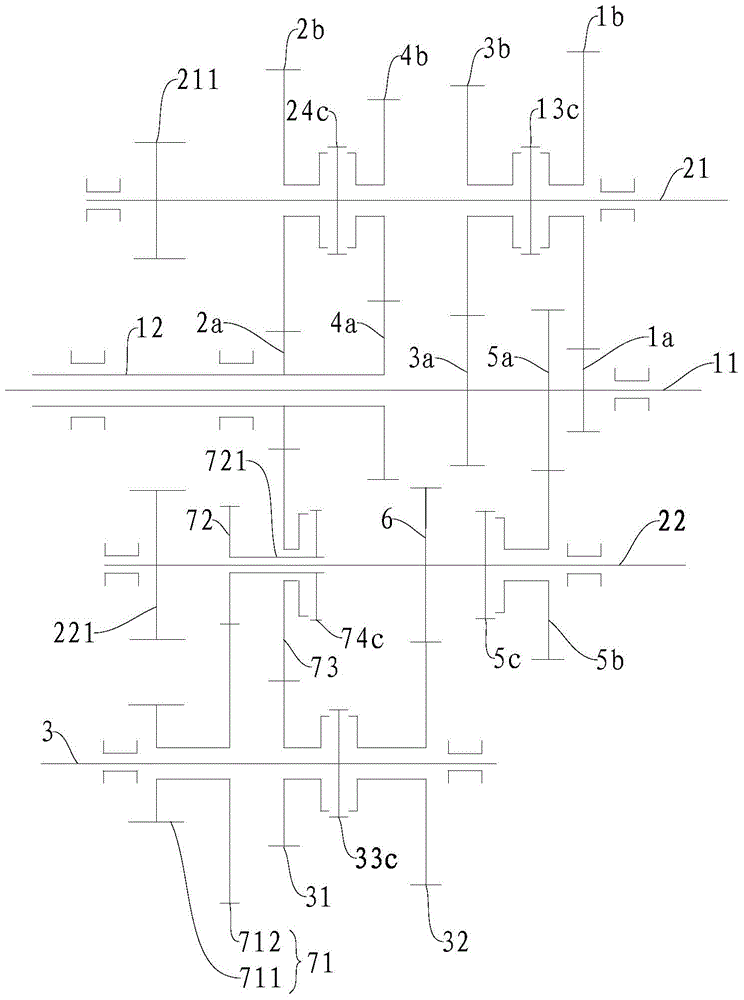

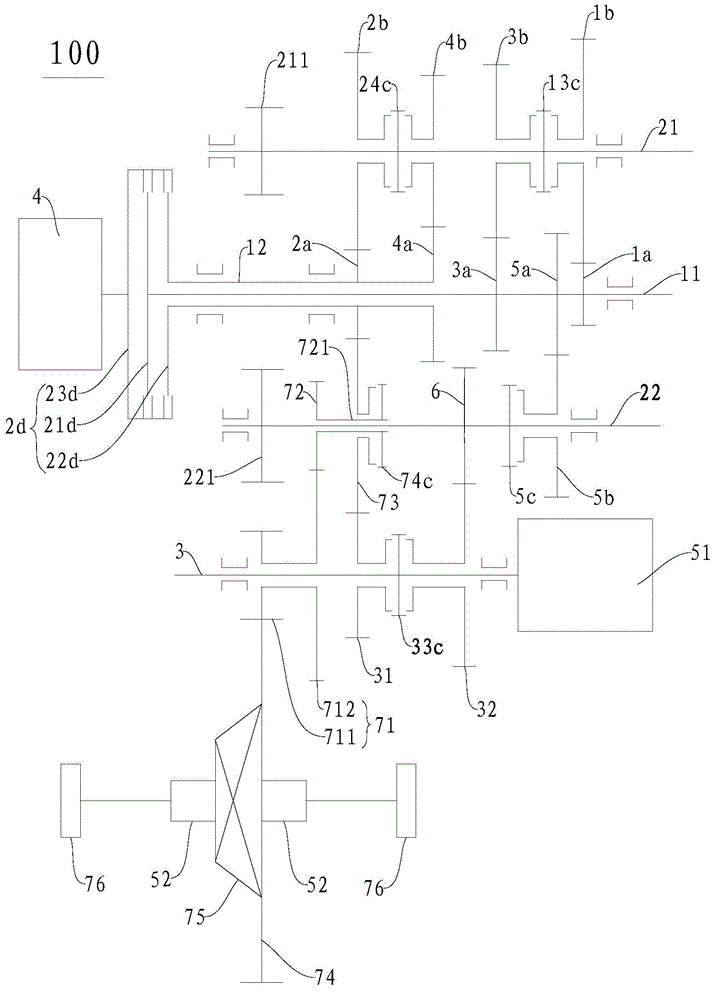

[0176] like image 3 As shown, the engine 4 is connected to the input end 23d of the dual clutch 2d, the first output end 21d of the dual clutch 2d is connected to the first input shaft 11, the second output end 22d of the dual clutch 2d is connected to the second input shaft 12, The input end 23d of the clutch 2d and the first output end 21d and the second output end 22d of the double clutch 2d may be disconnected at the same time, or the input end 23d of the double clutch 2d may be connected with the first output end 21d and the second output end of the double clutch 2d. One of the two output terminals 22d is engaged, or the input terminal 23d of the dual clutch 2d may be simultaneously engaged with the first output terminal 21d and the second output terminal 22d of the dual clutch 2d.

[0177] The second input shaft 12 is a hollow shaft structure, the first input shaft 11 is a solid shaft, the second input shaft 12 is coaxially sleeved on the first input shaft 11, and a par...

Embodiment 2

[0238] like Figure 4 As shown, the powertrain 100 in this embodiment is image 3 The main differences of the drivetrain 100 shown in are at the reverse intermediate gear 72, the intermediate idler 73 and the reverse synchronizer 74c. In this embodiment, the reverse idler gear 72 and the idler idler 73 are adjacent to the second output shaft 22, and the reverse gear synchronizer 74c is provided on the idler idler 73 and used to engage the reverse idler gear 72. For the rest it is possible to image 3 The power transmission system 100 in the embodiment is basically the same, and will not be repeated here.

Embodiment 3

[0240] like Figure 5 As shown, the powertrain 100 in this embodiment is Figure 4 The main difference in the drivetrain 100 shown in is the configuration of the intermediate idler gear 73 . In this embodiment, the intermediate idler gear 73 is configured as a double gear and has gear portions 731 , 732 , wherein one gear portion 731 meshes with the second gear driving gear (ie, with the gear driving gear on the one of the input shafts) ), the other gear part 732 meshes with the first gear 31 of the motor power shaft. For the rest it is possible to Figure 4 The power transmission system 100 in the embodiment is basically the same, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com