Angle-cutting slicing machine

A slicer and oblique cutting technology, which is applied in metal processing and other directions, can solve the problems of low slicing efficiency, unsanitary conditions, and high labor costs, and achieve the effects of high slicing efficiency, low labor intensity, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

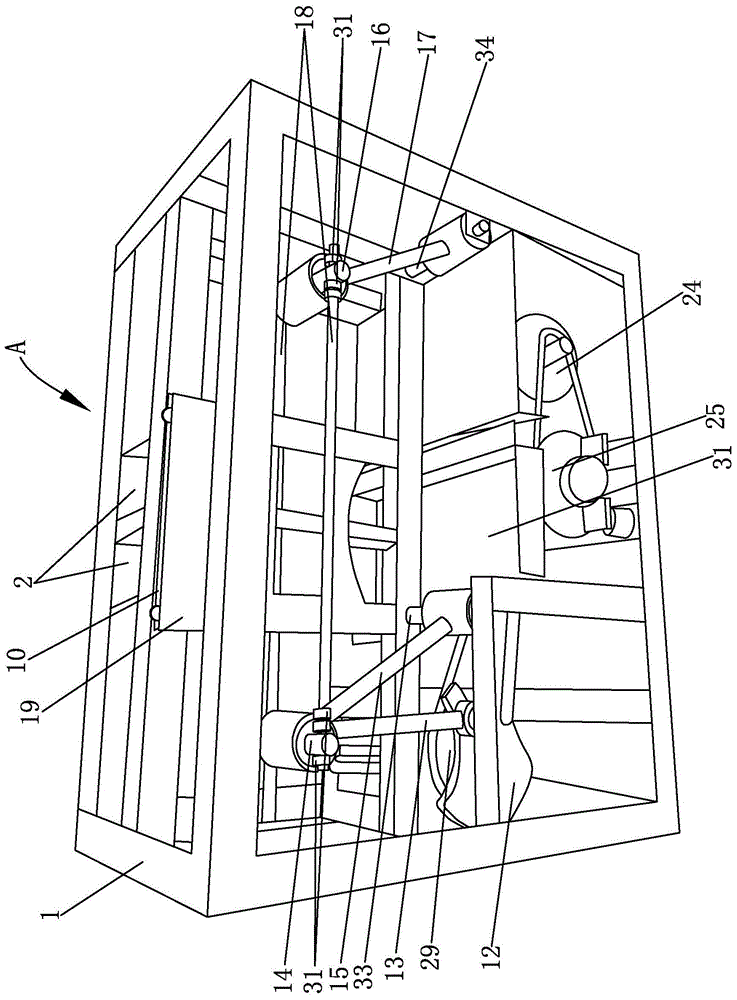

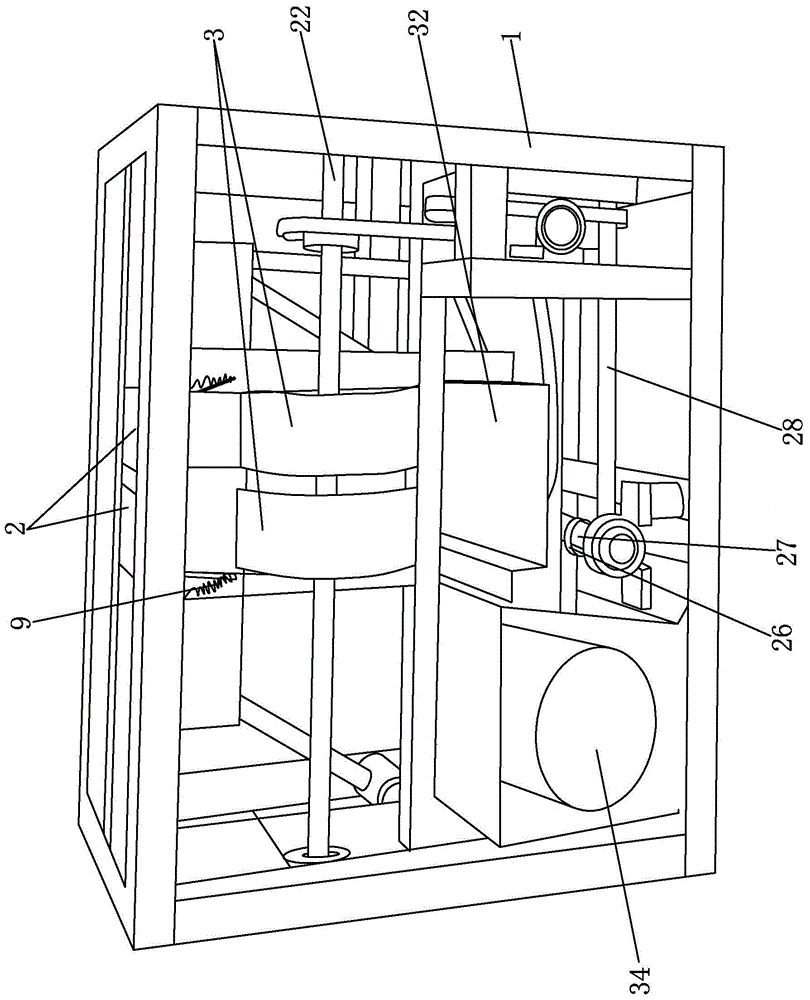

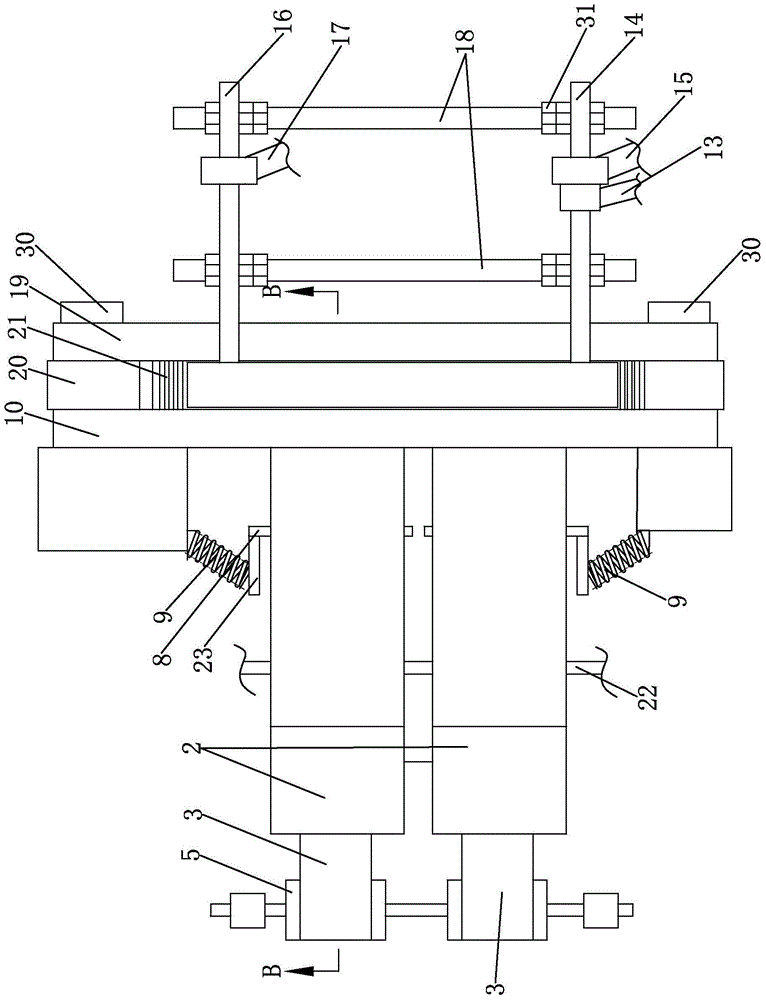

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0027] Such as Figures 1 to 4 As shown, a kind of oblique slicer mainly consists of a frame 1, a meat feeding mechanism, a slicing mechanism, a blade driving mechanism and a transmission mechanism. Wherein, the frame 1 is a rectangular frame structure and is formed by welding angle irons. For attractive in appearance, also can be provided with stainless steel or aluminum alloy casing (not shown in the figure) outside frame 1, and have meat feeding port on the casing, and slice mouth.

[0028] The frame 1 is provided with a meat feeding mechanism, a slicing mechanism, a blade driving mechanism and a transmission mechanism. Wherein, the number of the meat delivery mechanism is at least one, and these meat delivery mechanisms are arranged side by side in the horizontal plane, and the number of the meat delivery mechanism is two in this case. Each meat delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com