Distillatory kettle for plant sesame oil

A technology of distillation pot and sesame oil, applied in the field of distillation pot, can solve the problems of inability to recycle condensed water, short service life, inconvenient operation, etc., and achieve the effect of simple structure, convenient insertion and removal, and convenient collection

Active Publication Date: 2015-05-13

GUANGXI BONENG BIOMASS ENERGY TECH CO LTD

View PDF10 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, the present inventors found that some of the above-mentioned disclosed distillation pots have unreasonable structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

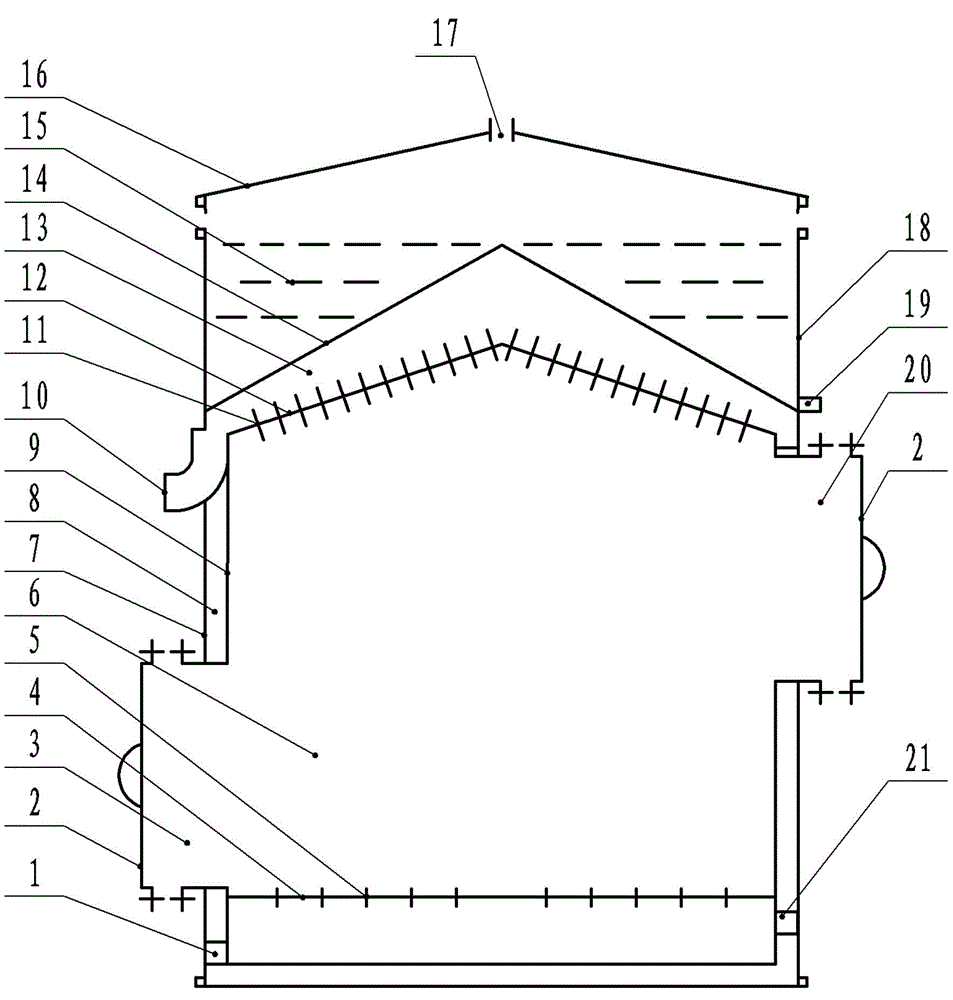

The invention discloses a distillatory kettle for a plant sesame oil. The distillatory kettle comprises a distillatory-kettle casing, wherein a distillatory-kettle liner is arranged in the distillatory-kettle casing, and a heat insulating layer is arranged between the distillatory-kettle casing and the distillatory-kettle liner; upper steam-opening baffles are arranged at the top of the distillatory-kettle liner, a feed opening is formed in the upper part of the distillatory-kettle liner, a discharge opening is formed in the lower part of the distillatory-kettle liner, a loading board is arranged at the bottom of the distillatory-kettle liner, a sewage discharging opening and a steam inlet are formed in the distillatory-kettle casing at the lower part of the loading board, steam collecting baffles are arranged at the upper parts of the upper steam-opening baffles, a steam collecting chamber is formed in a space between the upper steam-opening baffles and the steam collecting baffles, a steam guide opening is formed in the steam collecting chamber, a condensation water tank is arranged at the upper parts of the steam collecting baffles, a water outlet is formed in the lower part of the condensation water tank, covers for the condensation water tank are arranged on the condensation water tank, and a water inlet is formed in the covers for the condensation water tank. The distillatory kettle disclosed by the invention has the characteristics that the service life is long, the operation is convenient, the distilling efficiency is high, the heat energy of the condensation water tank can be sufficiently utilized.

Description

technical field [0001] The invention relates to the technical field of stills, in particular to a plant sesame oil still using steam as a heat source, which is suitable for distilling plant spices and aromatic oils, such as extracting fennel oil from branches and leaves of star anise trees or extracting rosin from turpentine waste residue. Background technique [0002] Plant spices and sesame oil distillers are important equipment for spice processing. In spice producing areas, the branches and leaves of star anise trees are rich in fennel oil, which can be used for medicinal purposes. It is a pity that the branches and leaves are not used every year! Distillation is the ideal way to extract fennel oil from the branches and leaves of the star anise tree; in addition, the turpentine industry also uses distillation to separate turpentine and rosin. [0003] The use of distillation requires the use of still pots. The open literature also reports some stills, for example: [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D3/02C11B9/02C11B1/16

Inventor 李而宏

Owner GUANGXI BONENG BIOMASS ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com