Process for making Wuyi rock tea

A production process and tea technology, which is applied in the field of Wuyi rock tea production process, can solve the problems of many product quality and safety factors, difficult standardization and automation, and unstable quality, so as to reduce personnel input, stabilize product quality, and tea grade Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

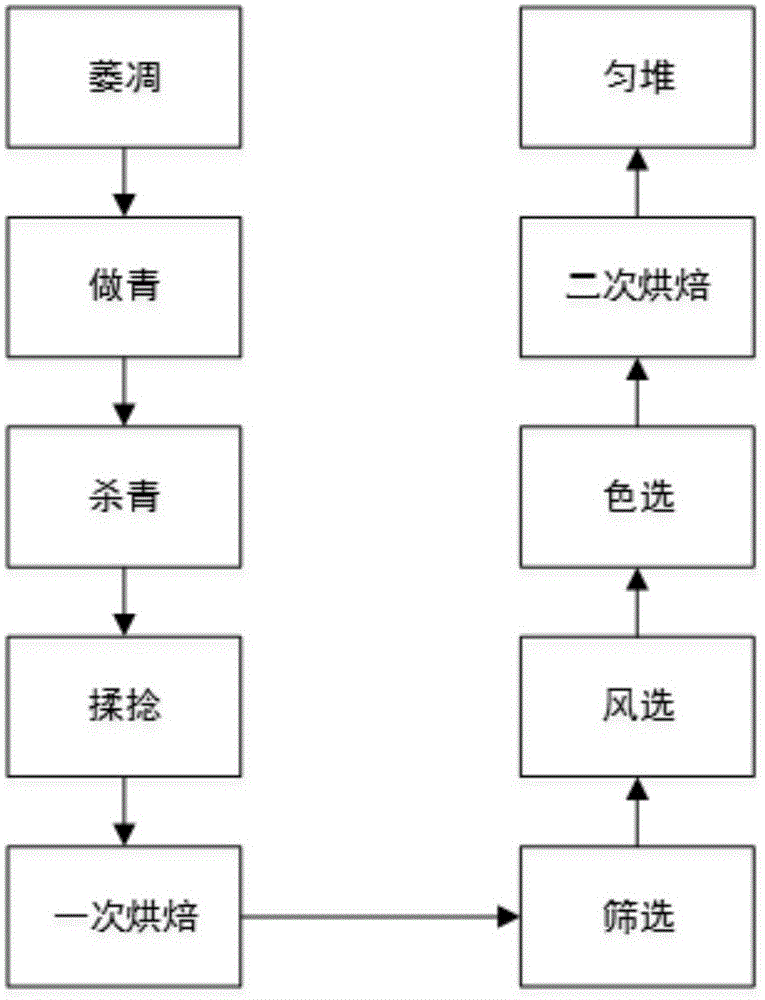

[0020] See figure 1 , figure 1 It is a flow chart of the Wuyi rock tea production process of the present invention. A production process of Wuyi rock tea, which sequentially comprises the following steps: withering, greening, finishing, rolling, primary baking, screening, winnowing, color sorting, secondary baking, and even stacking.

[0021] Among them, the withering includes the following steps, using sunlight to wither, spreading the leaves to a thickness of 2-3 cm, and performing 2-4 times of turning according to the intensity of sunlight during the period, and after the end, the water loss rate of the green leaves is 25%-30%, and the total time is 30min-90min , and then moved into the room for natural withering, the thickness of the spread leaves is 3-5 cm, and it is turned once an hour for 4h-6h. The water loss rate of green leaves is 35%-40%, that is, the withering ends.

[0022] Among them, greening includes the following steps of shaking greens and drying greens. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com