Generation system of welding process guide system for structural part

A welding process and guidance system technology, applied in special data processing applications, instruments, data processing applications, etc., can solve the problems of difficult data search, lack of association of documents, low efficiency of compilation process, etc., to improve design efficiency and reduce operation. cost, the effect of ensuring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

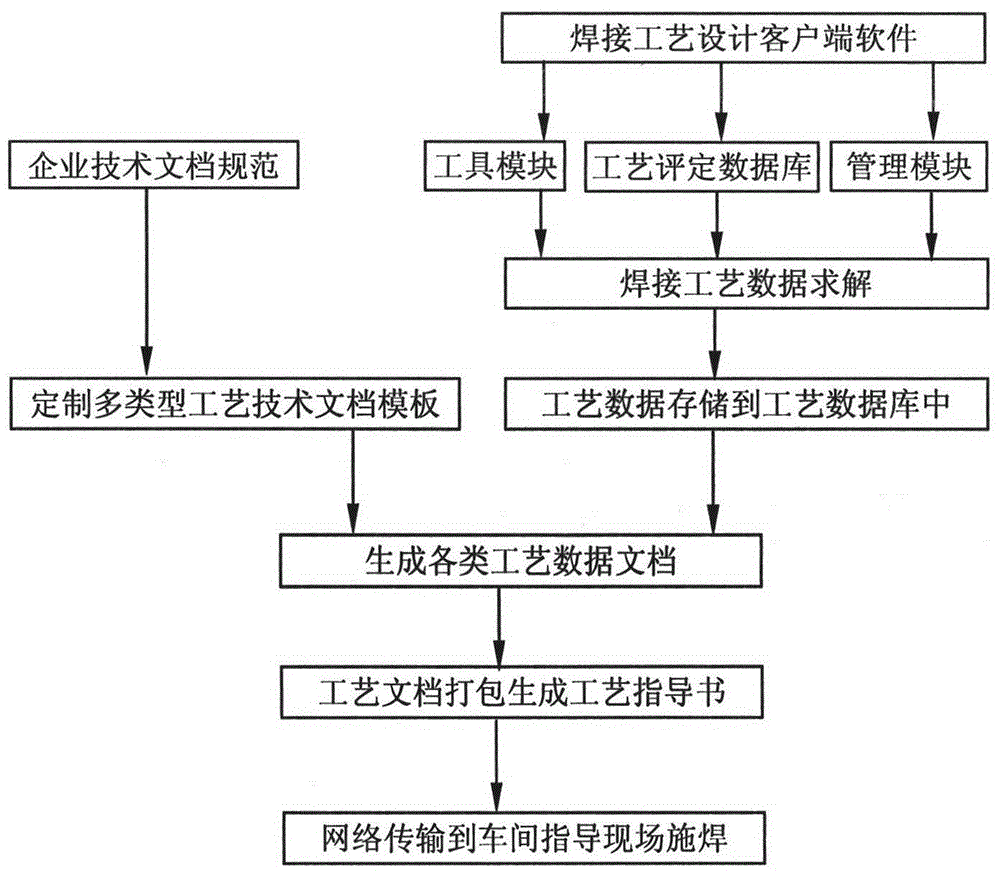

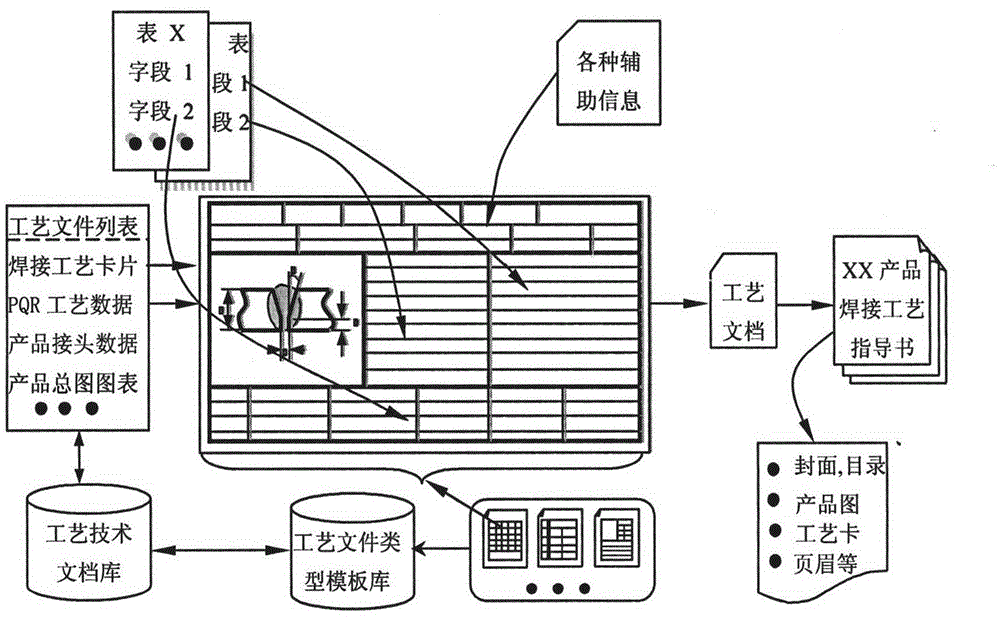

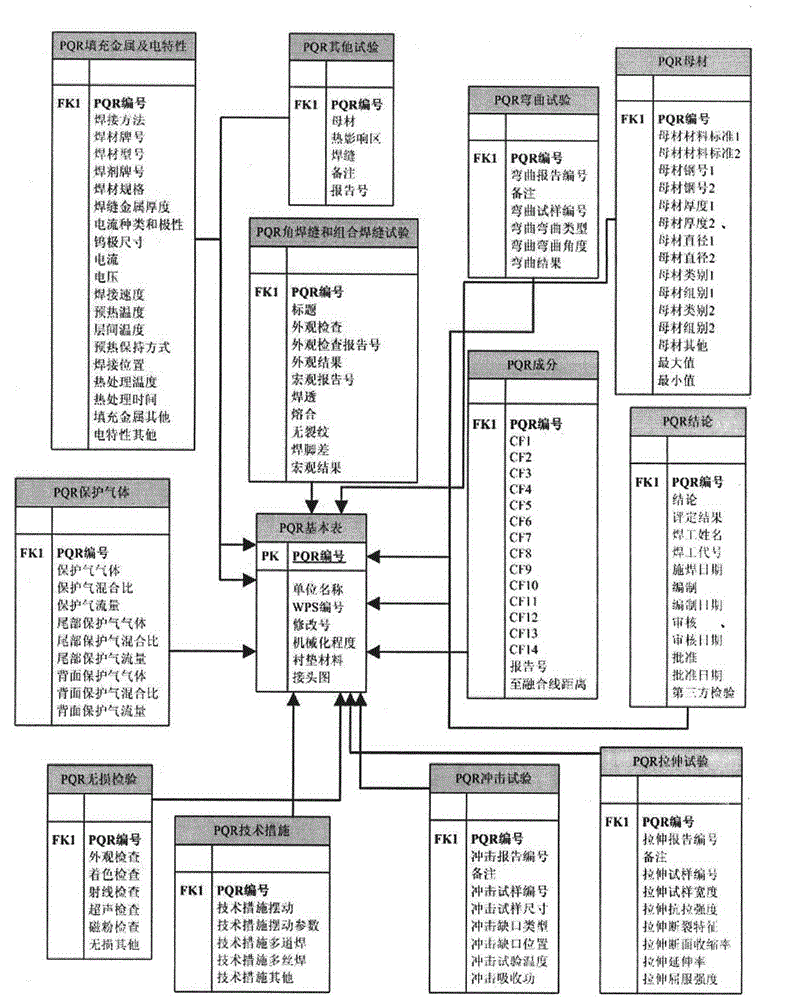

[0015] exist figure 1 Among them, the present invention provides a kind of generation method of structural parts welding process guidance system, and its implementation is in conjunction with SQL 2000 database management system, crystal report module design and realization in Visual C++ environment, and concrete realization steps are as follows: Step 1 : According to the needs of the enterprise, the process technology management template is designed. The template is presented as a series of standardized electronic forms. The cells in different areas of the form represent the corresponding types of information. Different process data are required at different stages of the process. Different process data are also required, and the information structure and expression form of process technical documents corresponding to different product structures, welding methods, and different joint forms are different. Multi-type templates are used to realize open data templates. The types o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com