Dry core-taking device and core-taking method for soft rock

A technology for coring device and soft rock, applied in sampling device and other directions, to achieve the effect of fast and efficient coring efficiency, simple and reliable coring method, and reducing heat concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

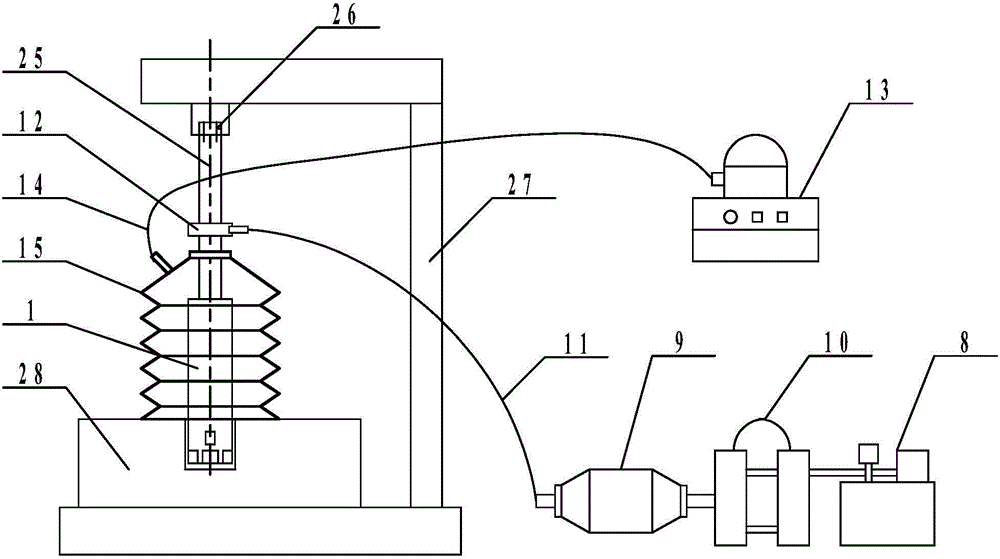

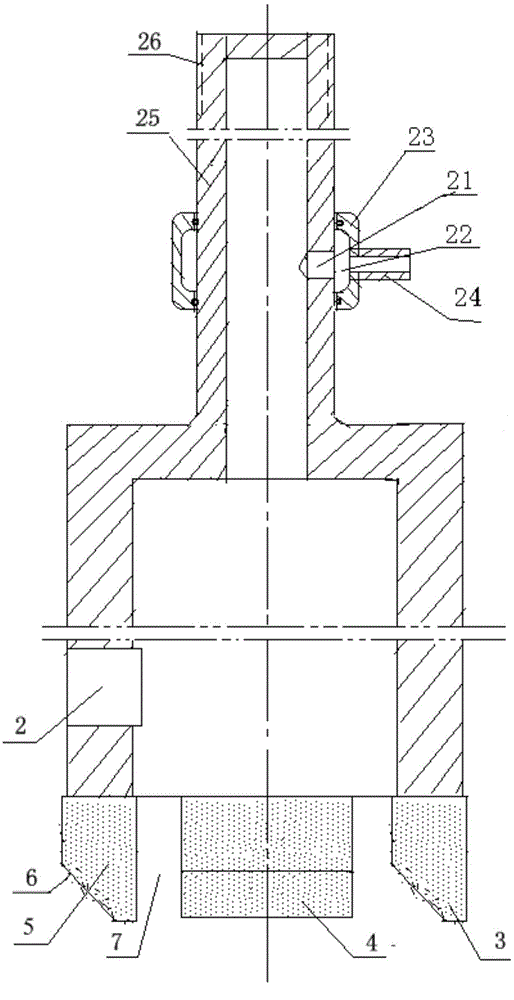

[0033] Such as figure 1 —The dry-type coring device for soft rock shown in 5, which includes a coring drill bit, an internal wind cooling system and an external wind dust suction system, wherein:

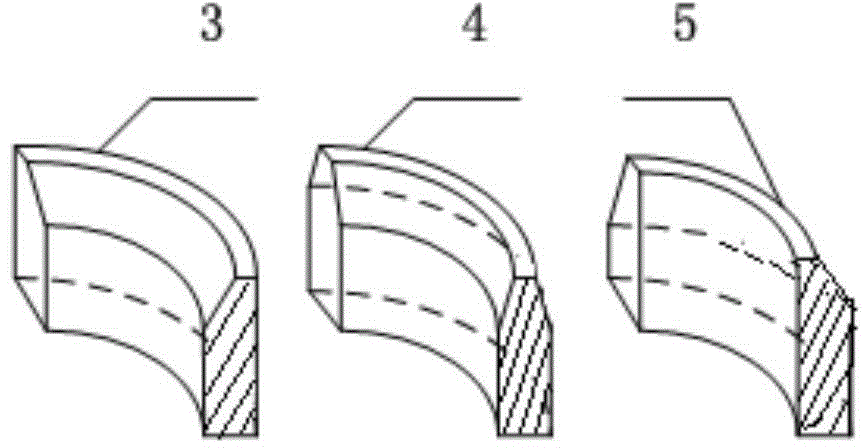

[0034] The core drill 1 is a hollow drill consisting of a grinding part, a drill body and a drill shank 25; the inner diameter of the drill is 50 mm, the length is 120 mm, and the wall thickness is 3 mm; wherein the grinding part of the core drill 1 is designed There are six grinding edges, and the grinding edges are designed into three types: inner edge 3, middle edge 4, and outer edge 5. The inner edge 3, middle edge 4, and outer edge 5 together form the grinding surface of the hollow drill bit; the grinding edge There is a gap with a width of 2 mm between the blades, which forms a debris flow groove 7; the outer surface of each grinding blade is uniformly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com