Photogrammetry method of liquid crystal display and application thereof

A technology of liquid crystal display and photogrammetry, which is applied in the direction of photogrammetry/video metrology, measuring devices, instruments, etc., can solve the problems that cannot be realized, the definition cannot meet the requirements, and the field of view of the camera is limited, so as to achieve low cost, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

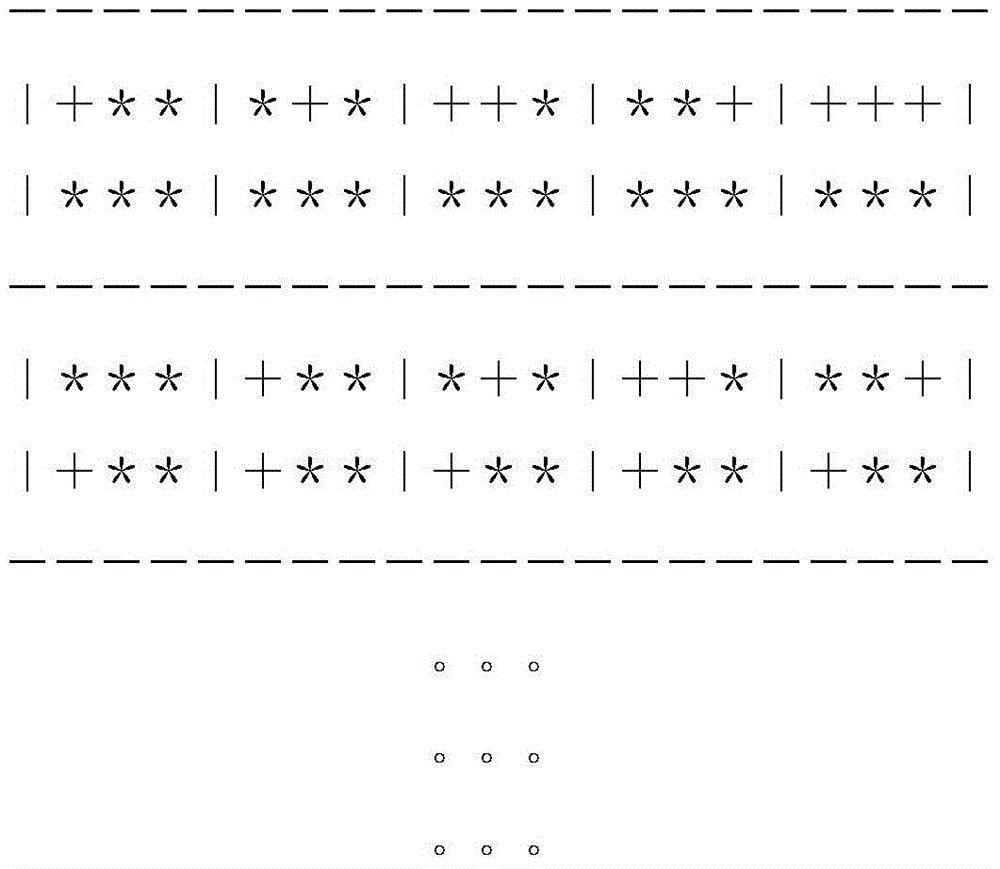

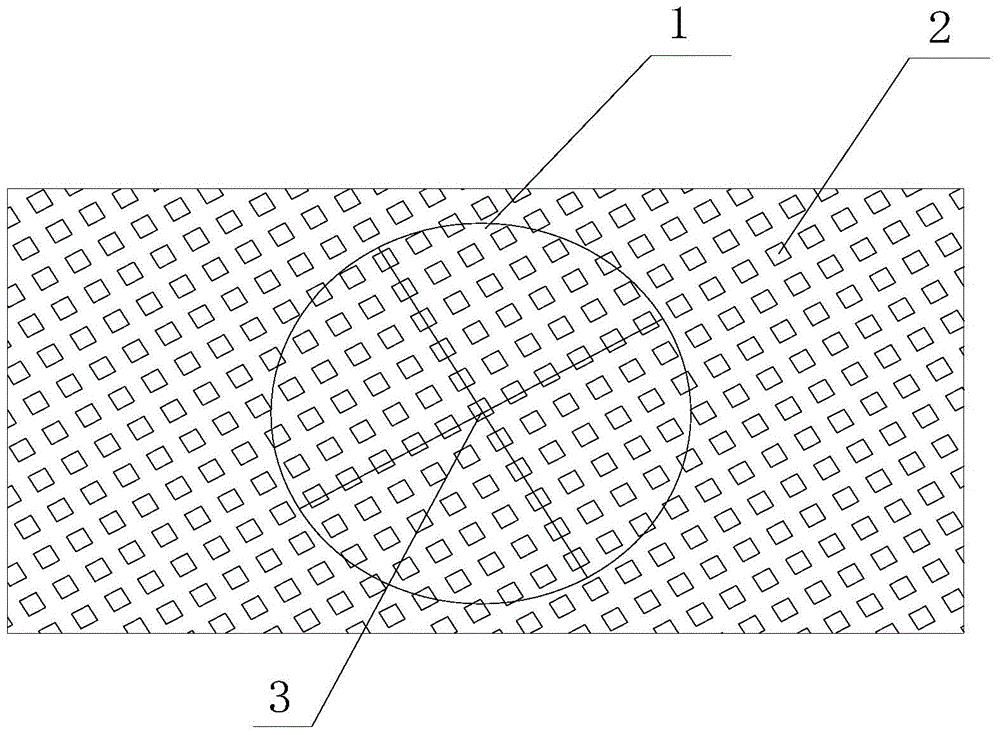

[0031] The invention discloses a photogrammetry method of a liquid crystal display, which is used for measuring the two-dimensional spatial coordinates of a point to be measured on a liquid crystal display. The point to be measured is located in the camera field of view 1 of an industrial camera. In this embodiment, the point to be measured is a camera The center point of the field of view.

[0032] Wherein the liquid crystal display adopts the liquid crystal display commonly used now. The new oled display is under development, and the price / performance ratio is not very good, but it is still usable. LCD screens of various sizes, such as mobile phone LCD screens, are also available. Industrial cameras are also commonly used. With a suitable lens, objects can be viewed at a microscopic level in a suitable field of view (similar to the working situation of a tool microscope). Cameras of various sizes, such as tiny cameras from the mobile phone industry, are also available. Th...

Embodiment 2

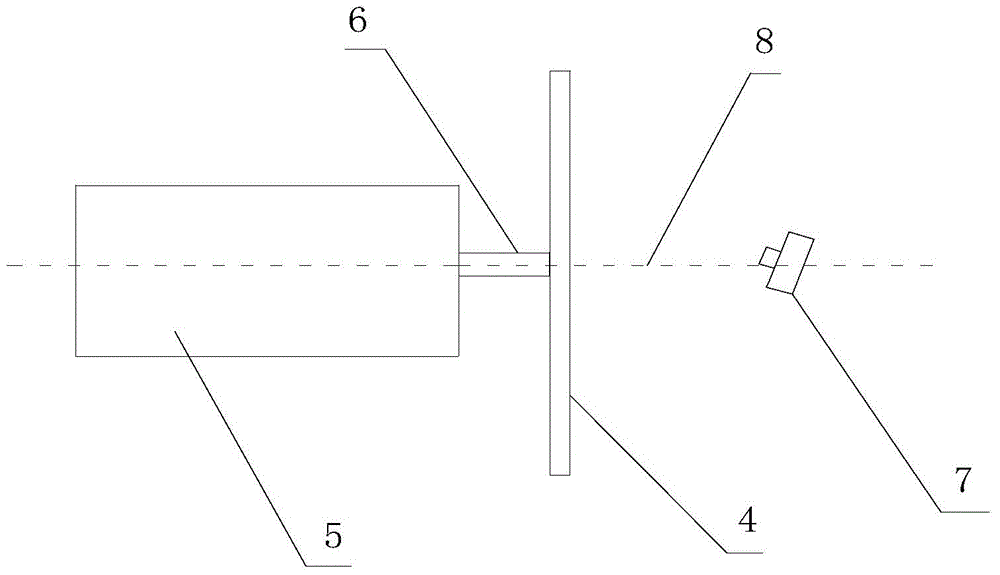

[0048] The difference with Embodiment 1 is that this embodiment discloses another solution of the method for measuring angular displacement, and the industrial camera 7 is fixed on the device under test 5, such as Figure 4 shown. The method described in this scheme includes: the industrial camera 7 is fixed on the rotating end 6 of the device under test 5 and rotates together with the rotating end 6, and the coordinates of the center point 3 of the camera field of view at the initial position are measured at least by the photogrammetry method, and finally The coordinates of the center point 3 of the camera field of view at the position, and the coordinates of any center point 3 of the camera field of view between the initial position and the final position, calculate the angular displacement; wherein the rotation center of the industrial camera 7 relative to the rotating end 6 The axis 8 is arranged eccentrically, and the liquid crystal display 4 is installed on the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com