Assembling type heat preservation shear wall structure system and construction process

A shear wall and assembled technology, applied in the direction of walls, building components, building structures, etc., to achieve the effects of promoting industrialization models, uniform models, and good anti-seepage and anti-leakage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is described in detail below in conjunction with accompanying drawing:

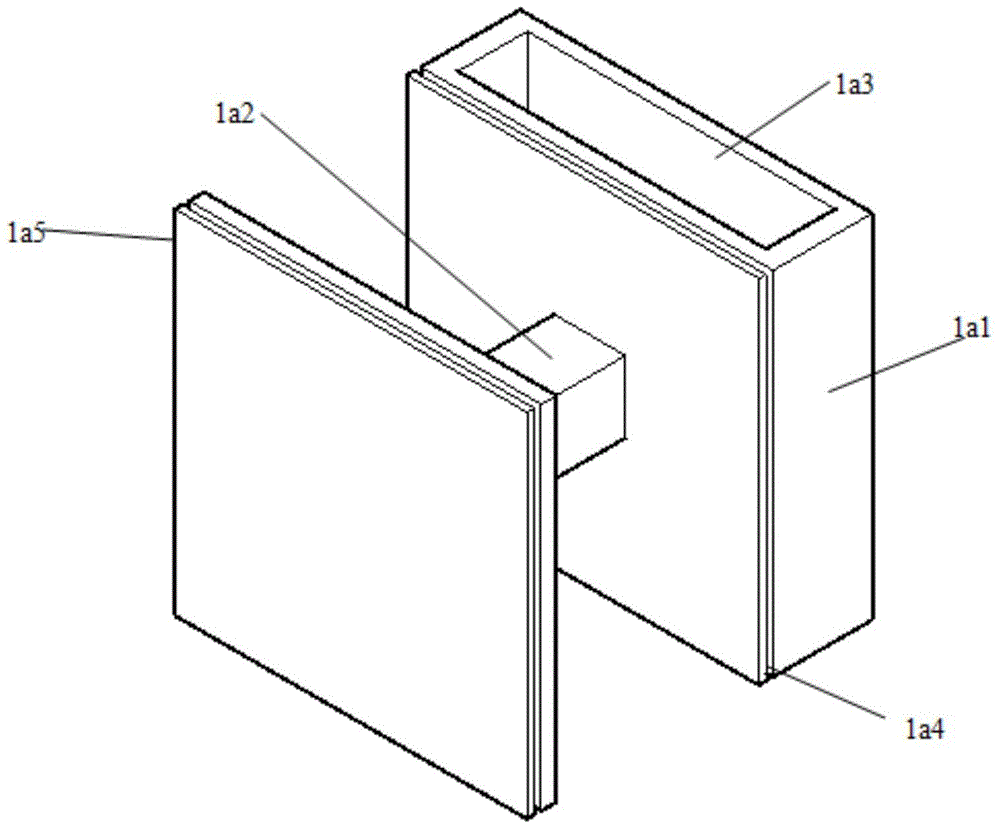

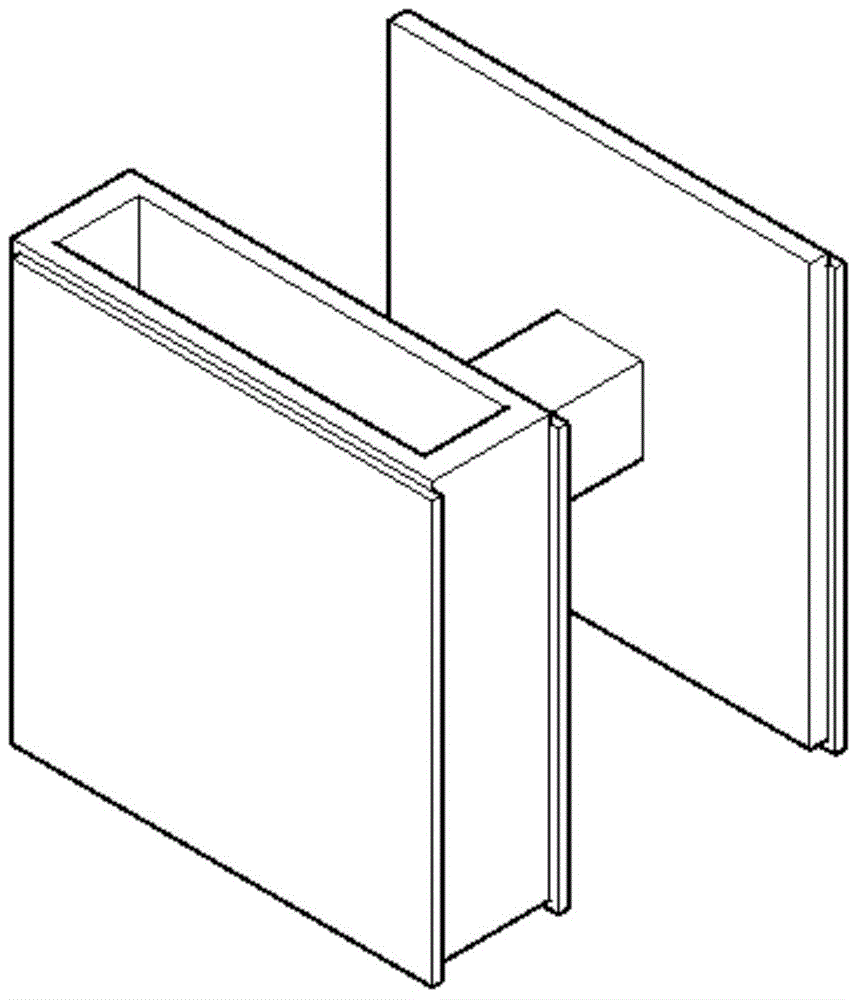

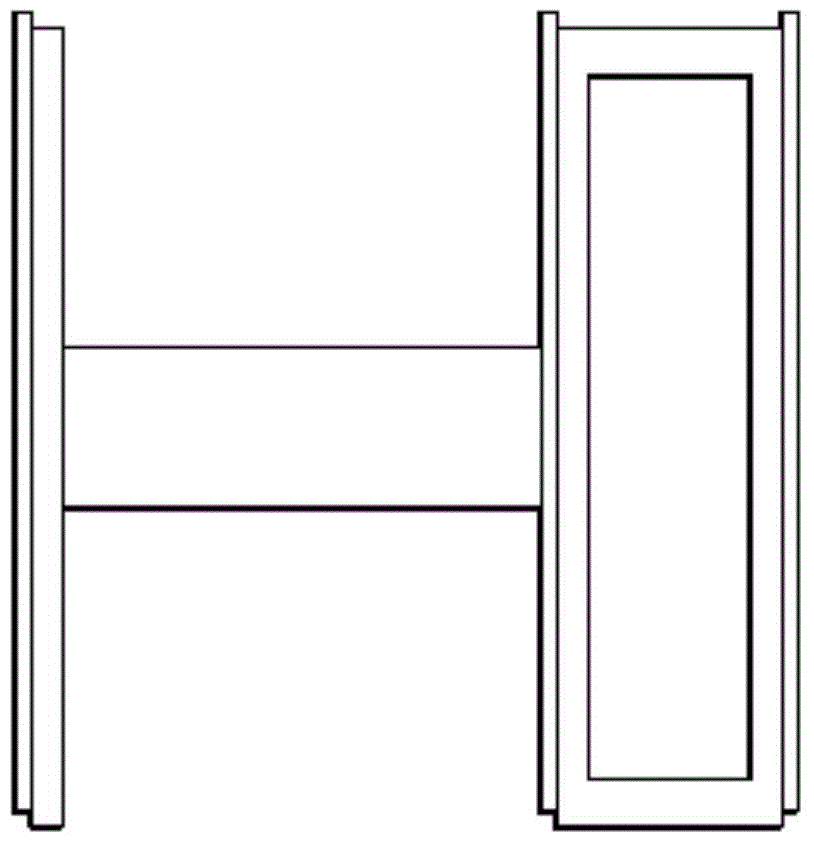

[0053] It is divided into two structural systems: exterior wall and interior wall. The exterior wall structure system has the function of heat preservation. The external wall assembled shear wall structure system is formed by the assembly of the external wall formwork unit. The external wall formwork unit consists of two main boards and a tie rod. The two main boards have different shapes and the same plane size. The thickness of the main board inside the wall is 30mm~100mm , the thickness of the outer main board is 100mm ~ 200mm, the board has a through hole vertically, filled with insulation material, the tie rod is preferably a rectangular cuboid in cross section, placed horizontally in the middle of the two main boards, and rigidly connected; The concave-convex grooves on the side are butted, and the vertically adjacent template units are docked through the concave-convex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com