A stable structure and a drilling platform construction method based on the stable structure

A technology of drilling platform and construction method, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., and can solve problems such as the inability of steel casings to be self-stabilized, bridge construction disasters, and large wave forces, so as to avoid construction Safety risk, simple construction process, effect of increasing plane rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

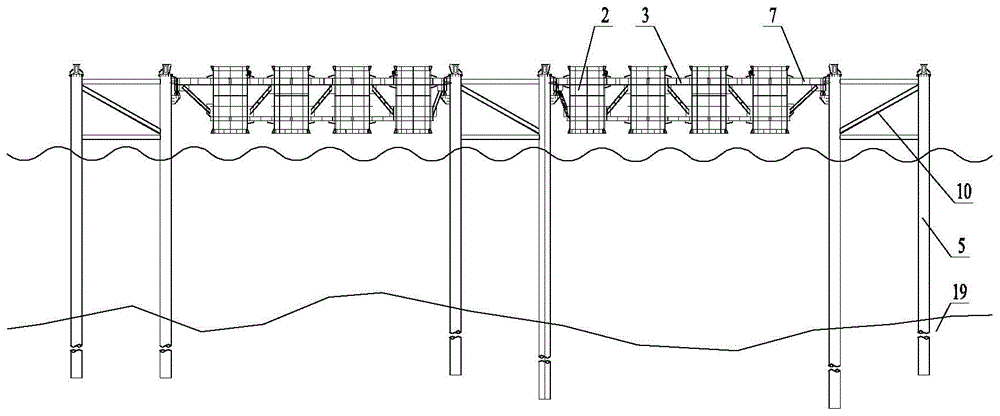

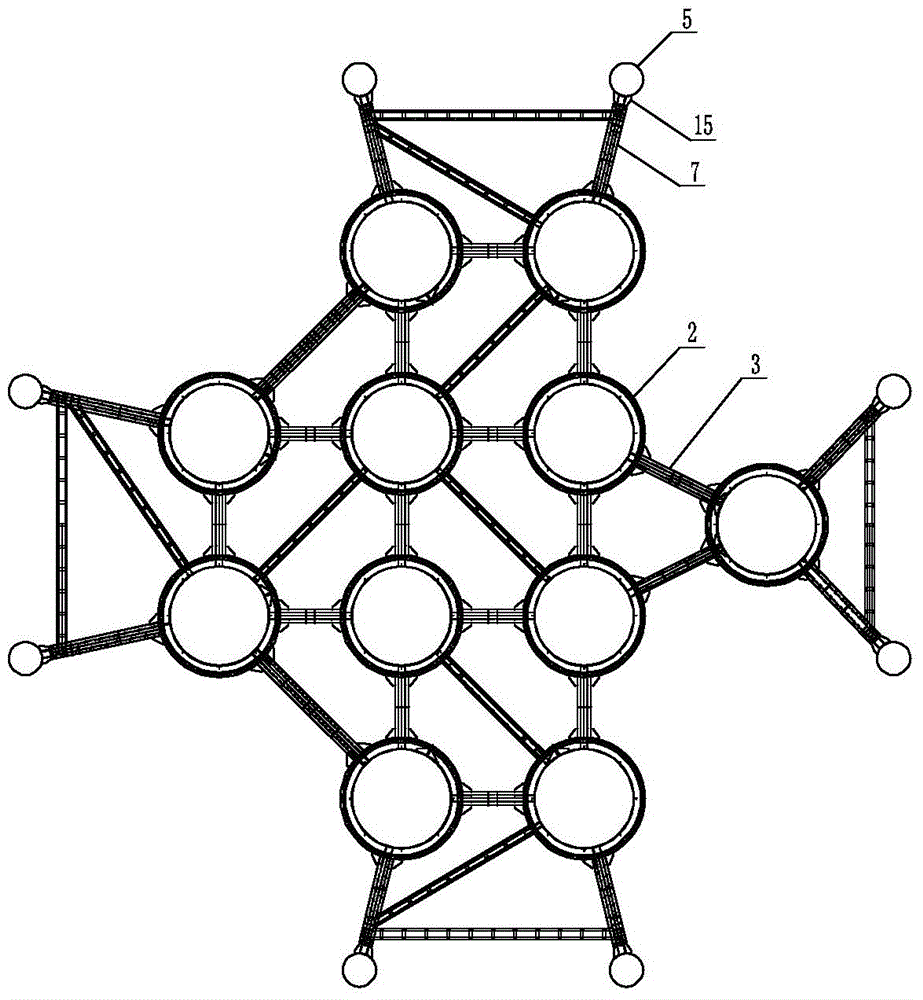

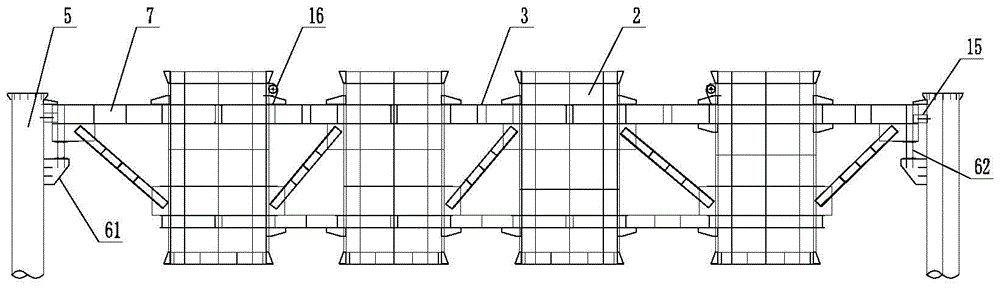

[0038] like Figure 1 to Figure 5 As shown, a stable structure includes several steel pipe piles 5 vertically inserted in the riverbed 19, several platform frames and several groups of position adjustment devices 6. There are a plurality of rectangular frames, and each rectangular frame is provided with a platform frame, and each platform frame is connected to the steel pipe piles 5 corresponding to the side of the rectangular frame through several groups of intermediate couplings 7 . Each platform frame includes several steel casings 2, and each steel casing 2 is provided with a casing stiffening structure for strengthening the steel casing 2 to prevent excessive local stress and deformation of the steel casing 2, and the steel casing 2 The inner diameter of the steel casing 2 is 10-20cm larger than the outer diameter of the steel casing 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com