Pressurized sudden expansion sudden drop circular jet energy dissipator

A circular jet, energy dissipator technology, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve the problem of small cavitation number of water flow on the side wall of the stilling pool, large flow velocity at the bottom and side wall of the stilling pool, and stilling force. The problems of cavitation and cavitation damage in the pool can be achieved, and the effect of aeration and corrosion reduction is good, the water surface fluctuation is reduced, and the energy dissipation is sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

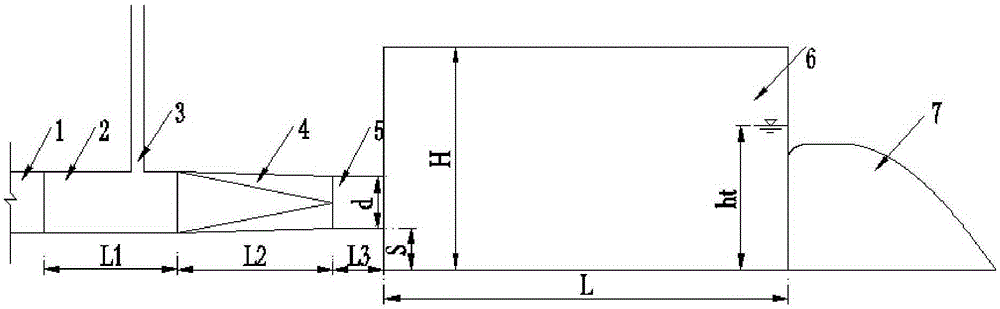

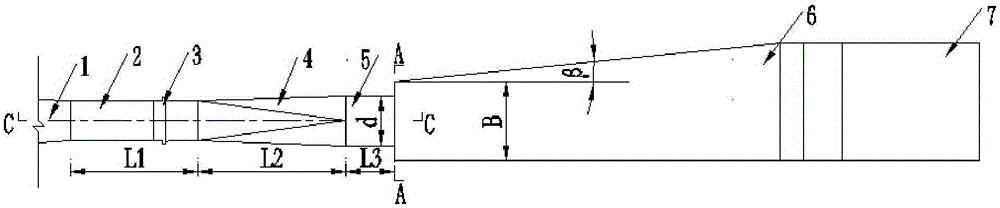

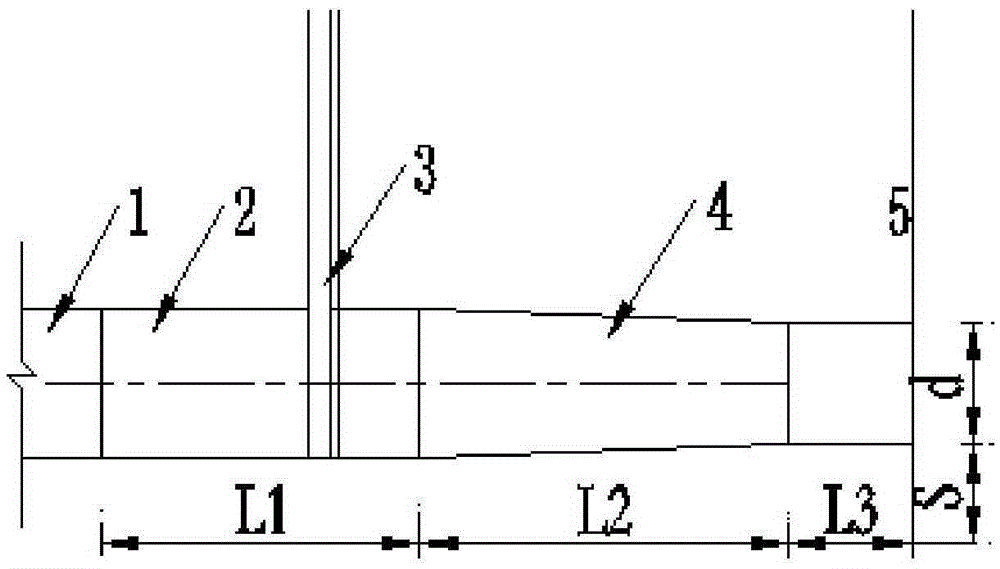

[0047] In this embodiment, the sudden expansion and sudden drop circular jet energy dissipation works such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes the first transition section 1 connected with the pressurized flood discharge tunnel, the rectangular sluice section 2, the second transition section 4, the equal-diameter circular pipe section 5, the stilling tank 6, and the overflow weir 7; the first transition section 1 The shape of the flow hole changes from circular to rectangular gradually from the upstream end to the downstream end. The size of the flow hole is the same as that of the flow hole of the rectangular lock chamber section 2; the length L1 of the rectangular lock chamber section 2 is 12.95m, and the size of the flow hole is: width×height=4m×6m, with a gate 3; stilling pool 6 It is an asymmetric gradually expanding rectangular stilling basin, and the unilateral diffusion angle of the stilling basin is β =6°, the length of the stillin...

Embodiment 2

[0050] The sudden expansion and sudden drop circular jet energy dissipator in this embodiment differs from Embodiment 1 in that: the length L2 of the second transition section 4 = 10m, the length L3 of the equal-aperture circular pipe section 5 = 30m, and the height of the drop sill S=5m (0.6d

[0051] Test results: The normal storage level of the reservoir is 380m, and the discharge flow is 736m 3 / s, the flow velocity at the outlet of the equal-diameter circular pipe section 5 is 36.4m / s, and after the water flow enters the stilling pool and the water body in the stilling pool frictionally mixes for a certain distance, the length to reach the bottom plate of the stilling pool and attach to the wall again is 47m. The flow velocity at which the water flow reaches the wall-attachment point on the bottom plate of the stilling tank is 10.82m / s, and then the water flow adheres to the wall, and the flow velocity gradually decreases with the movement of the water flow to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com