Template sewing machine

A sewing machine and template technology, which is applied to sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of increasing the difficulty of transportation and installation of template sewing machines, difficulties in maintenance and debugging of template sewing machines, and large worktables, etc., to achieve maintenance And the effect of convenient debugging, convenient transportation and installation, easy maintenance and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

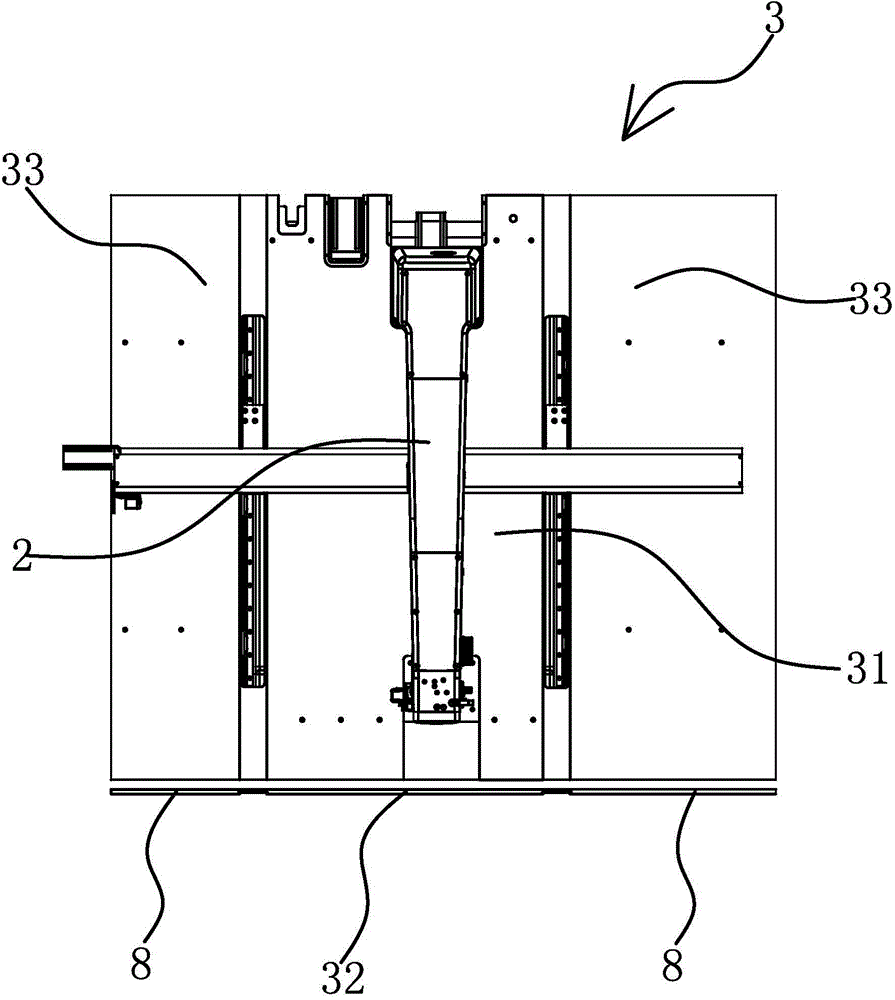

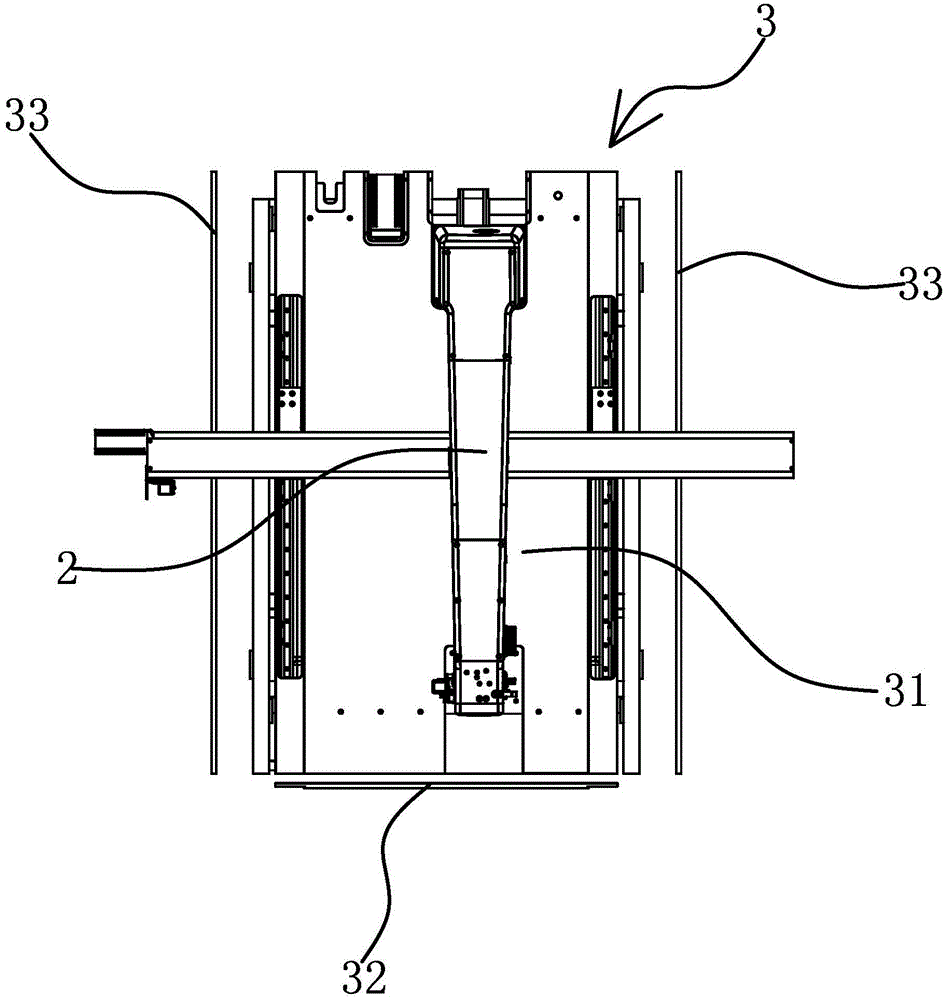

[0032] This template sewing machine comprises frame 1, machine head 2, platen body 31, front plate 32, front plate connector 4, front rotating shaft 5 and locking mechanism one.

[0033] Specifically, as figure 1 and Figure 4As shown, the platen body 31 is fixed on the frame 1 , and the machine head 2 is located on the platen body 31 . The front panel 32 is located on the side corresponding to the front end of the front panel body 31 and the machine head 2. Two strip-shaped front panel connectors 4 are respectively fixed on the bottoms of both sides of the front panel 32. The front panel connectors 4 protrude from the front panel 32. bottom. One end of each front panel connecting member 4 close to the platform body 31 is respectively rotatably connected with the frame 1 through the front rotating shaft 5 , and the front rotating shaft 5 is located below the bottom of the front panel 32 . As a preferred solution, the front panel connecting member 4 is a square hollow struct...

Embodiment 2

[0040] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the movable platen 8 is detachably connected to the side of the side platen 33 close to the front plate 32, and the current When the platform 32 and the side platform 33 are located at the same level as the platform body 31 , the outer surfaces of the movable platform 8 are respectively flush with the corresponding outer surfaces of the front panel 32 .

Embodiment 3

[0042] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the locking mechanism includes a front locking lever and a locking bolt, and the front locking lever is hinged on the front panel connector 4 On, the end portion of front locking lever has through hole 1, is fixed with locking bracket 1 on frame 1, and locking bracket 1 has the locking part 1 that is elongated, and locking part 1 end has locking hole 1, and front locking lever can be wound around The swing of the hinge makes the through hole one and the locking hole one position just opposite, and the locking bolt one passes through the through hole one and the locking hole one to position the front locking lever on the locking bracket one.

[0043] During the use of the template sewing machine, the through hole on the front locking lever and the locking part on the locking bracket are positioned by tightening the locking b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com