Moving lifting device

A technology of lifting device and moving mechanism, applied in the direction of lifting device, lifting frame, etc., can solve the problems of inconvenient handling and movement, unable to adapt to uneven ground, etc., and achieve the effects of simple structure, reduced thickness and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

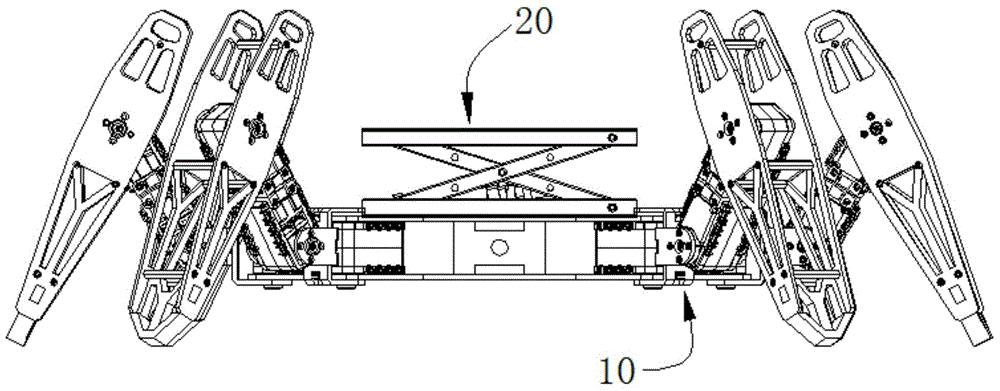

[0032] see figure 1 , which is a side view of a mobile lifting device according to a preferred embodiment of the present invention.

[0033] The mobile lifting device includes a moving mechanism 10 and a lifting mechanism 20 .

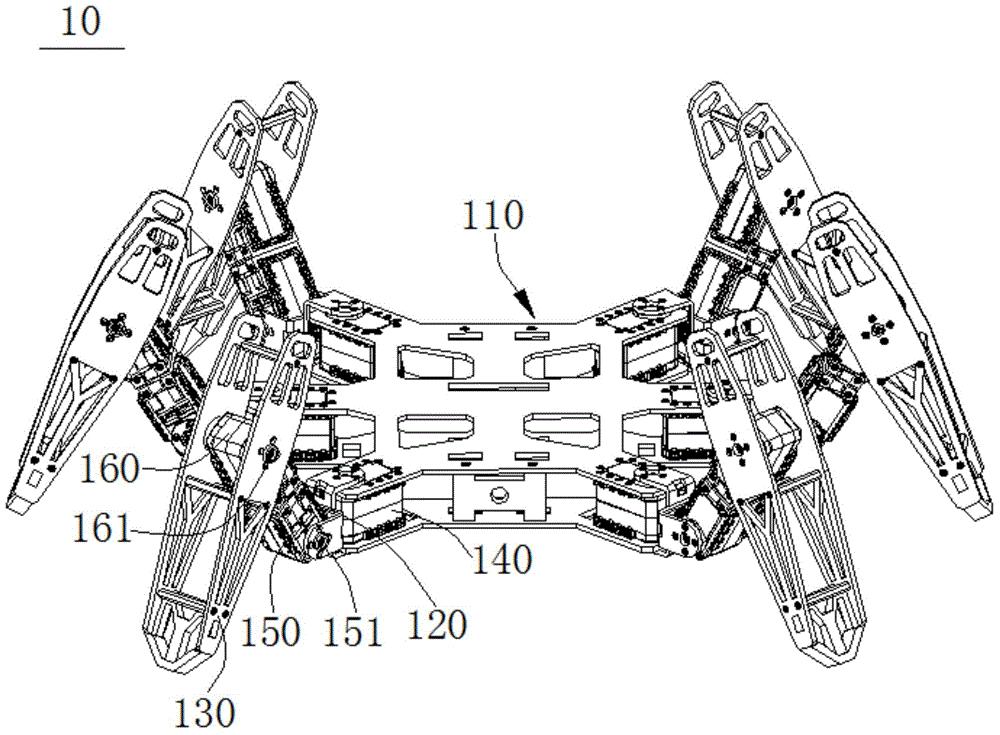

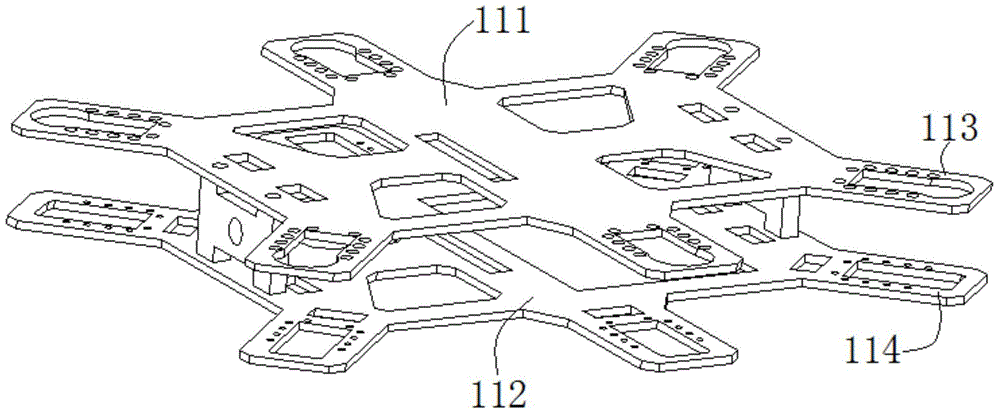

[0034] Please also refer to figure 2 , which is figure 1 The structural diagram of the moving mechanism 10. The moving mechanism 10 includes: a support plate 110 , a connecting portion 120 and a claw 130 . Six first motors 140 are arranged at intervals on a side of the support plate 110 , and the rotation axes of the first motors 140 are perpendicular to the support plate 110 . The connecting part 120 is drivingly connected with the rotating shaft of the first motor 140, the connecting part 120 is drivingly connected with the second motor 150, the rotating shaft 151 of the second motor 150 is perpendicular to the rotating shaft of the first motor 140, and the second motor 150 is fixed with The third motor 160 , the rotation axis 161 of the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com