Grain packaging machine with automatically-adjusted seam height

An automatic adjustment and packaging machine technology, applied in packaging and other directions, can solve the problems that the adjustment position cannot be in place at one time, workers are inconvenient to operate, and time-consuming, etc., to improve the accuracy of stitching, improve stitching efficiency, and avoid labor and time-consuming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

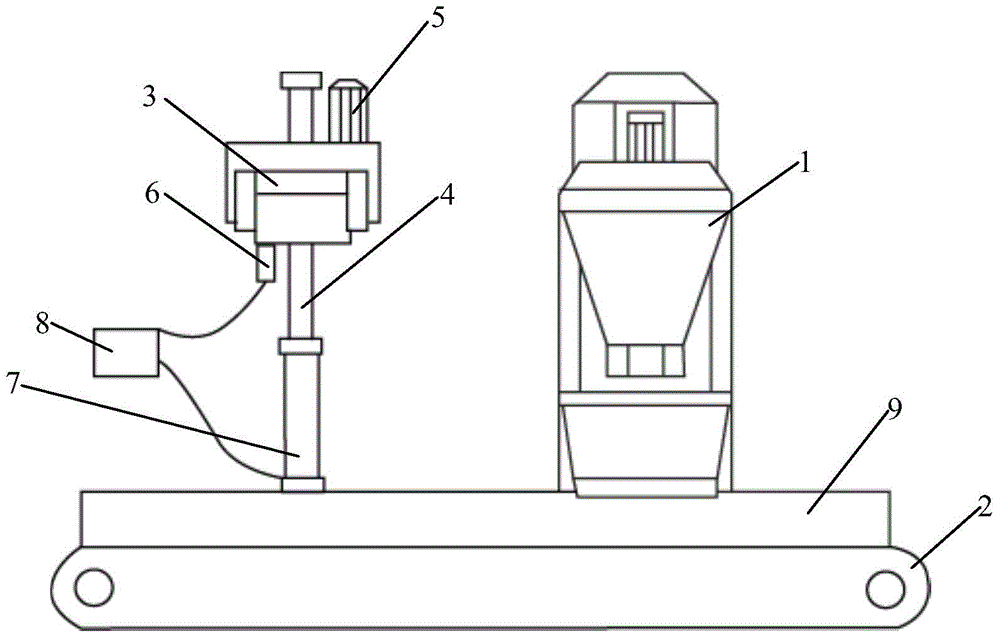

[0013] like figure 1 As shown, the present invention provides a grain packaging machine with automatic seam height adjustment, comprising a packaging machine body 1, a conveying platform 2, a sewing machine 3, a column 4, and a motor 5, the packaging machine body 1, the sewing machine 3 respectively arranged above the conveying platform 2, the bag sewing machine 3 is fixedly connected with the column 4 arranged below the bag sewing machine 3, the bag sewing machine 3 is fixedly connected with the motor 5, and is characterized in that it also includes Infrared sensor 6, lifting cylinder 7, controller 8, described infrared sensor 6 is arranged on the bottom of described sewing machine 3, described lifting cylinder 7 is fixedly connected with described column 4, described lifting cylinder 7 is connected with described controller 8 connected, the controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com