Crawling robot worktable

A technology of crawling robots and workbenches, which is applied in the fields of motor vehicles, transportation and packaging, etc., can solve the problems of low production efficiency, difficulty in meeting mechanization, rapidity, and automation, and achieve the effects of improving work efficiency, saving manpower, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

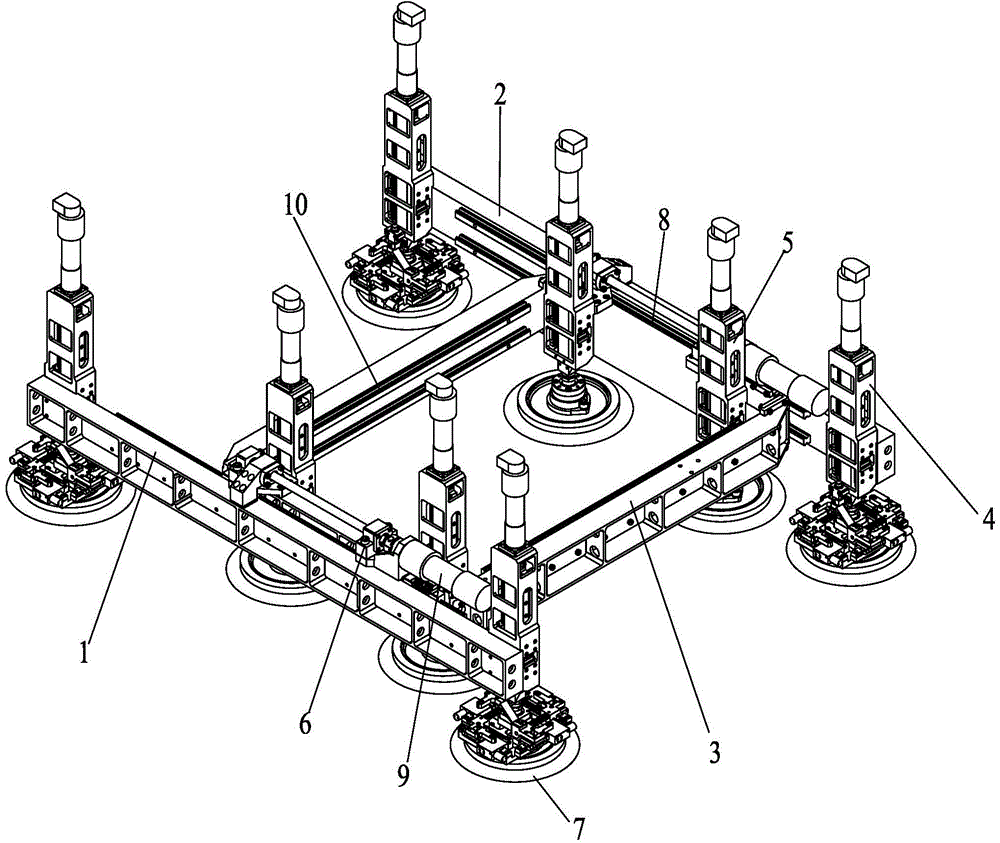

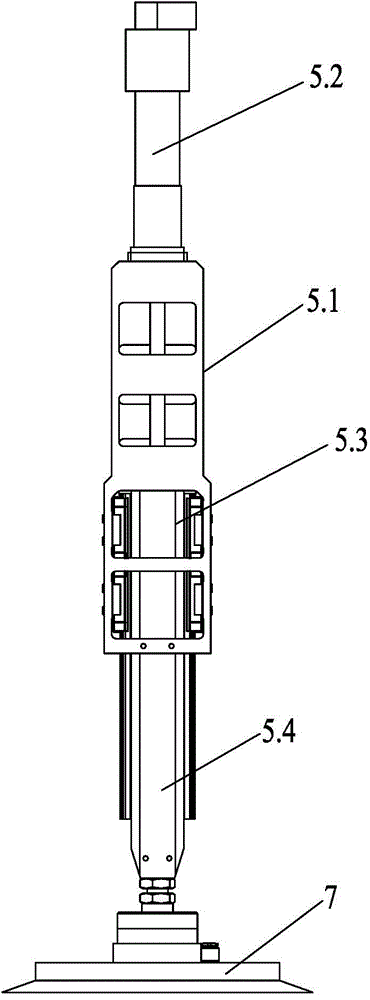

[0011] figure 1 Including the first outer frame 1, the second outer frame 2, the inner frame 3, the outer frame telescopic legs 4, the inner frame telescopic legs 5, the frame 5.1, the telescopic leg motor 5.2, the feed screw 5.3, the telescopic leg guide rail 5.4, Motor seat 6, suction cup 7, guide rail 8, outer frame feed motor 9, slide rail 10, etc.

[0012] Such as figure 1 As shown, the present invention is a workbench for an eight-legged crawling robot, comprising a first outer frame 1 and a second outer frame 2 arranged parallel to each other, and the opposite surfaces of the first outer frame 1 and the second outer frame 2 are A guide rail 8 is respectively fixed on the top, and the rectangular inner frame 3 is slidably connected to the guide rail 8. An inner frame telescopic leg 5 is respectively arranged at the inner four corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com