Embossing roller phase fine-tuning device for steel plate embossing machine

A technology of fine-tuning device and embossing roller, which is applied in decorative arts, embossed decorative parts, etc., can solve the problems of no registration, embossing roller pattern phase difference, phase synchronization gear meshing failure, etc., to achieve reasonable setting and device structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

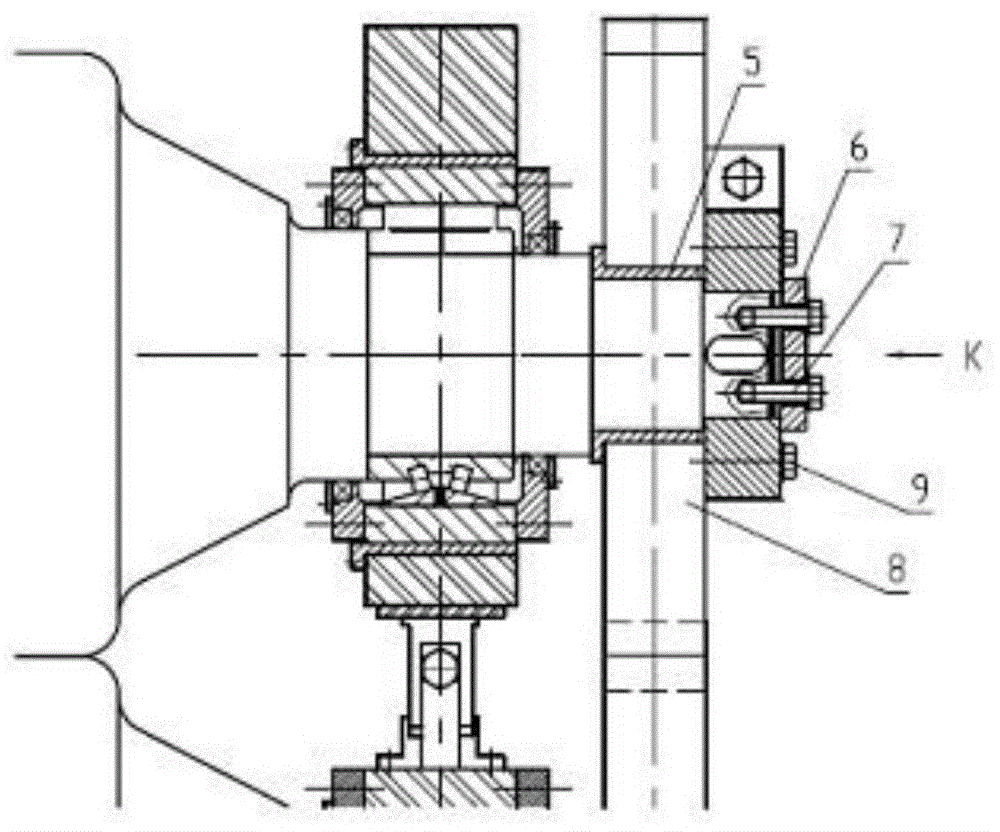

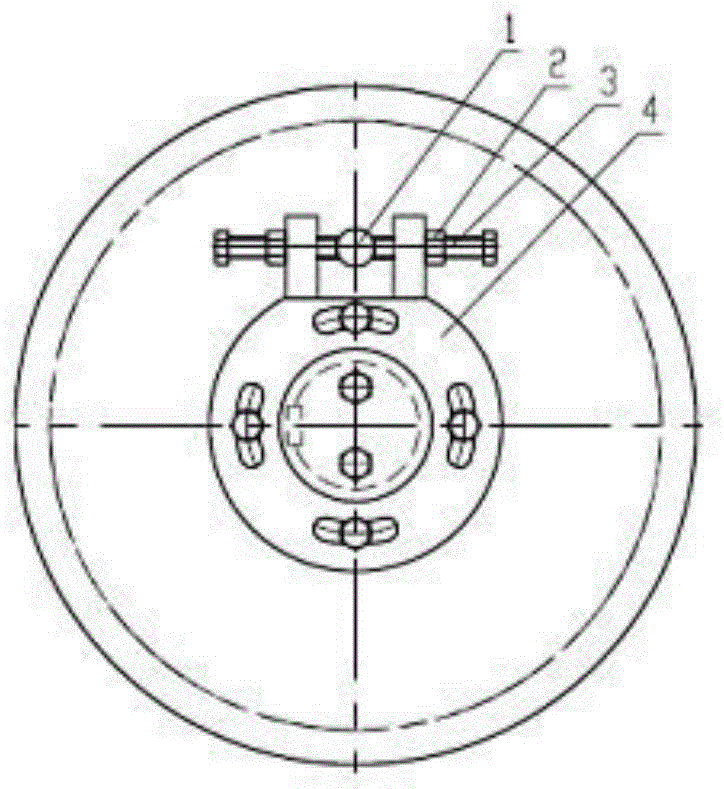

[0015] Embossing roller phase fine-tuning device for steel plate embossing machine, including fixed pin 1, nut 2, bolt 1 3, fine-tuning flange 4, sliding bearing 5, pressure plate 6, bolt 2 7, non-transmission embossing roller phase synchronization gear 8 and the third bolt 9, the fixed pin 1 is threadedly connected with the non-transmission embossing roller phase synchronization gear 8, and the fine-tuning flange 4 is fixedly connected to the end face of the non-transmission embossing roller phase synchronization gear 8 through the third bolt 9 , One end of the fixing pin 1 is provided with threads. The fine-tuning flange 4 is provided with a keyway, an arc-shaped long hole and a threaded hole, and the fine-tuning flange 4 is connected with the embossing roller key. When adjusting the phase of the embossing roller, the fine-tuning flange 4 is driven t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com