Household oil press

A technology for oil presses and home use, applied in presses, manufacturing tools, etc., can solve the problems of low oil extraction rate of oil plants, achieve high oil extraction rate, save oil extraction costs, and be easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

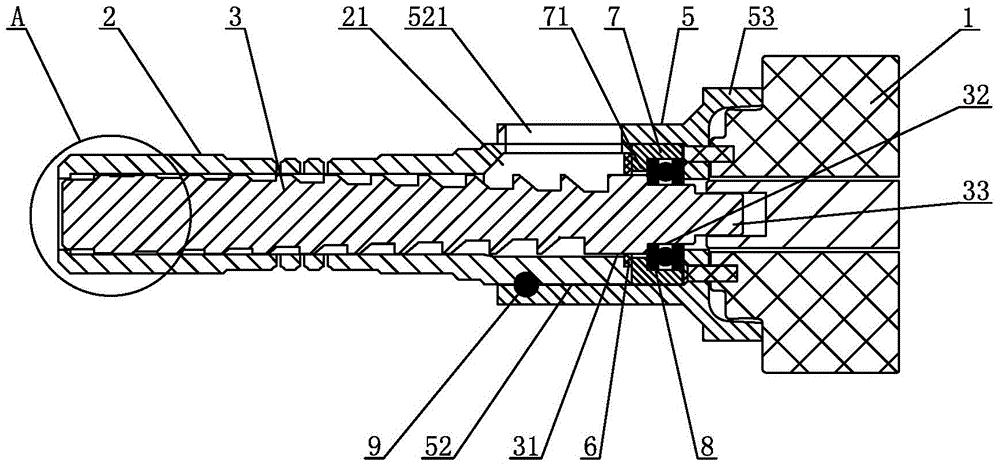

[0029] The present invention will be further described below with reference to the drawings and embodiments.

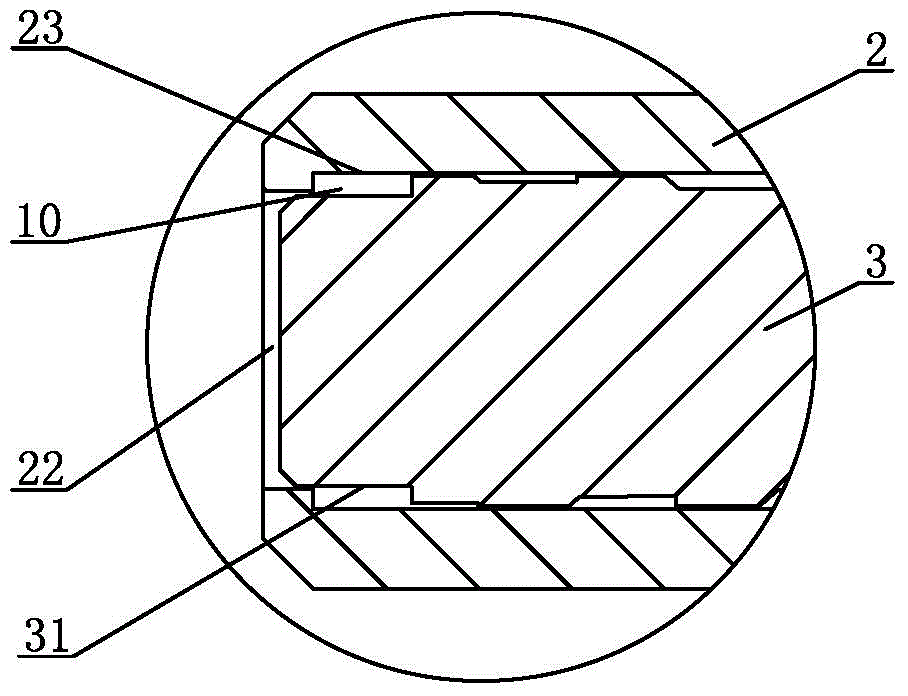

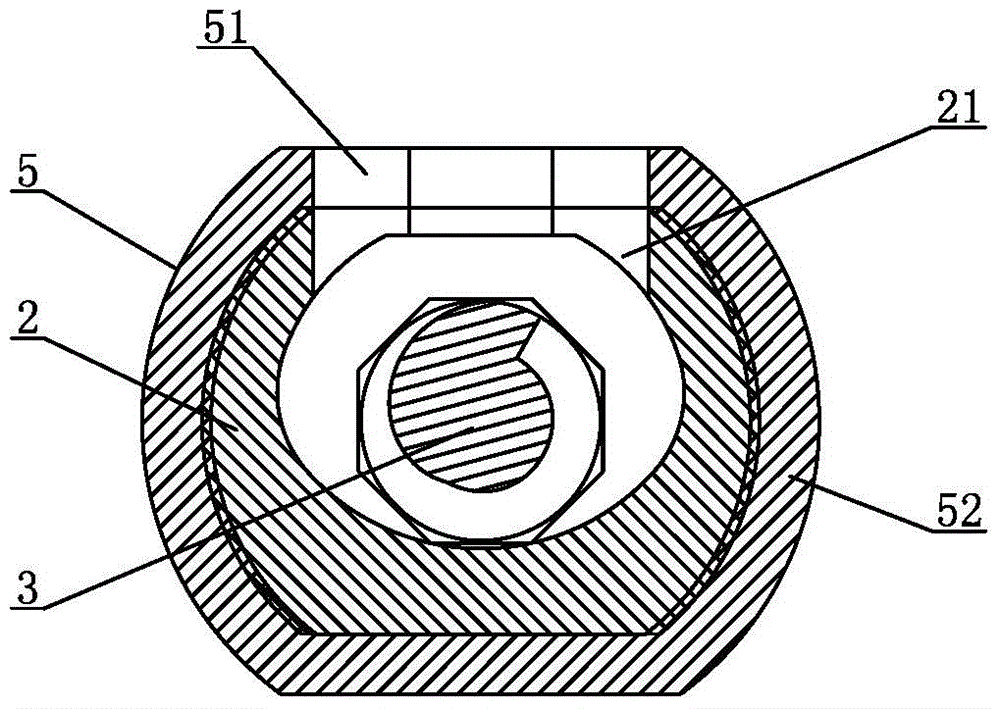

[0030] See Figure 1-Figure 5 , This domestic oil press includes a wave box 1, a press chamber 2 fixed on it, a screw 3 is arranged in the press chamber 2, and the head end of the screw 3 is in transmission connection with the wave box 1, and a feed is provided at the head end of the press chamber 2 The bin 21 and the tail end are provided with a slag discharge hole 22. The tail end of the press chamber 2 and the tail end of the screw 3 form an extrusion cavity 10 for temporarily storing oil and squeezing the oil. The slag hole 22 is in communication, and the size of the extrusion cavity 10 perpendicular to the longitudinal direction of the press chamber 2 is larger than the aperture size of the slag discharge hole 22.

[0031] Further, a press chamber extrusion section 23 is provided at the end of the inner cavity of the press chamber 2, and a screw extrusion section 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com