Method for machining universal ball pedestal

A processing method and technology for universal balls, applied in the field of machinery, can solve the problems of weak connection of universal balls, easy breakage, damage to the rod with high hardness, etc., so as to achieve a simple and easy processing method and easy to implement, and the connection is firm and smooth. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

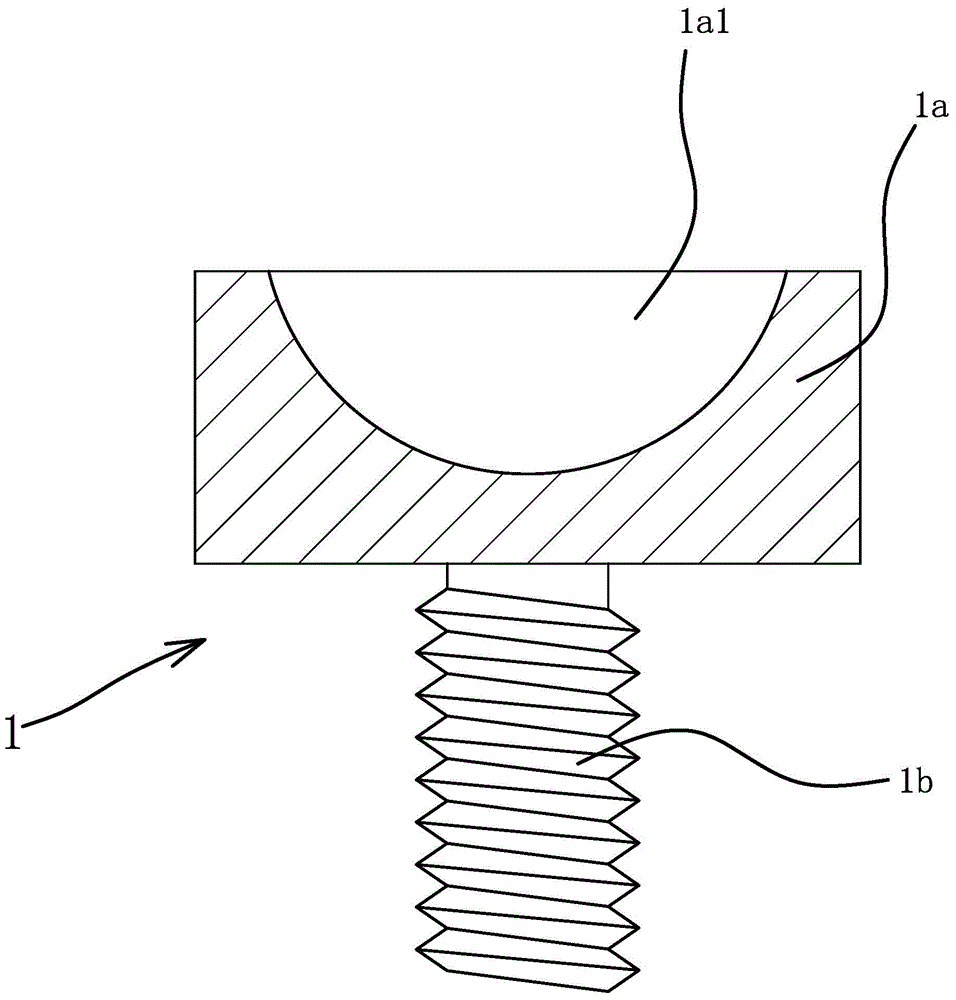

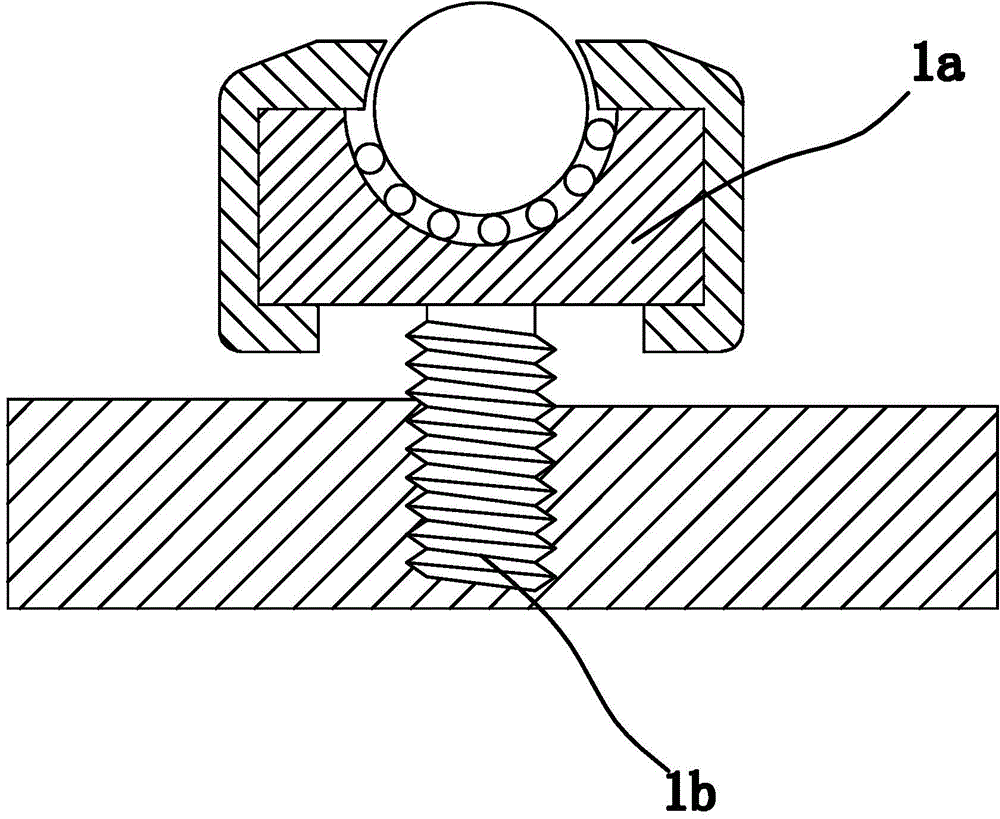

[0057] Such as figure 1 As shown, the universal ball base 1 includes a base head 1a and a base rod 1b that are connected as a whole. The base head 1a is cylindrical, the base rod 1b is rod-shaped, the base rod 1b has threads on the outside, and the base head The outer end of 1a has an aperture groove 1a1 recessed in a spherical surface. The inner end of the base head 1a and the inner end of the base rod 1b are integrally connected.

[0058] The processing method of the universal ball base includes the following steps:

[0059] A. Turning blank: cut off the raw material bar or obtain a set length of the bar blank by metal forging. After the bar blank is clamped on the lathe, the base is processed on the bar blank by turning processing method The head 1a is a semi-finished product.

[0060] After the semi-finished product is turned around and clamped on the lathe, the rod-shaped base rod portion 1b is processed by a turning method. In this embodiment, an additional process is adde...

Embodiment 2

[0071] The processing method of the universal ball base includes the following steps:

[0072] A. Turning blank: Cut off the raw material bar or obtain a set length of the bar blank by metal forging, and then clamp the bar blank on the lathe, and then process the base on the bar blank by turning processing method The head 1a is a semi-finished product.

[0073] After the semi-finished product is turned around and clamped on the lathe, the rod-shaped base rod portion 1b is processed by a turning method. In this embodiment, an additional process is added during the turning process, that is, chamfering the edges of the base head 1a and the base rod 1b. Of course, according to the actual situation, the edges of the base head 1a and the base rod 1b may also be rounded.

[0074] Finally, thread rolling or thread rolling is used to process the external thread on the base rod.

[0075] B. Machining caliber groove: The outer end of the base head 1a is rough turned by a turning method to obta...

Embodiment 3

[0083] The processing method of the universal ball base includes the following steps:

[0084] A. Turning blank: cut off the raw material bar or obtain a set length of the bar blank by metal forging. After the bar blank is clamped on the lathe, the head is processed on the bar blank by turning processing method Part 1a, a semi-finished product is obtained.

[0085] After the semi-finished product is turned around and clamped on the lathe, the rod-shaped base rod portion 1b is processed by a turning method. In this embodiment, an additional process is added during the turning process, that is, chamfering the edges of the base head 1a and the base rod 1b. Of course, according to the actual situation, the edges of the base head 1a and the base rod 1b may also be rounded.

[0086] Finally, an external thread is processed on the base rod 1b by a thread rolling or thread rolling processing method.

[0087] B. Machining caliber groove: The outer end of the base head is rough-turned by a tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com