Hot-line cleaner of silicon rubber insulator

A silicone rubber insulation and live cleaning technology, which is applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of silicone rubber insulators without cleaning tools, etc., to solve live cleaning and ensure a safe distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

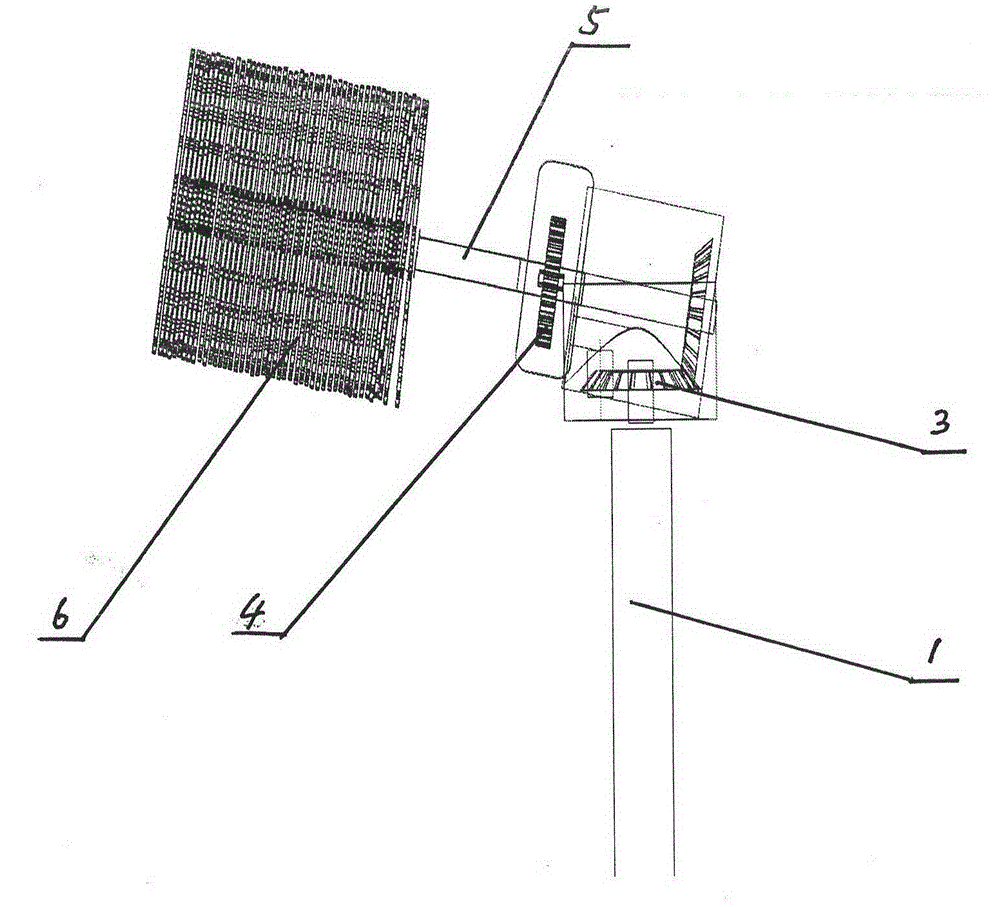

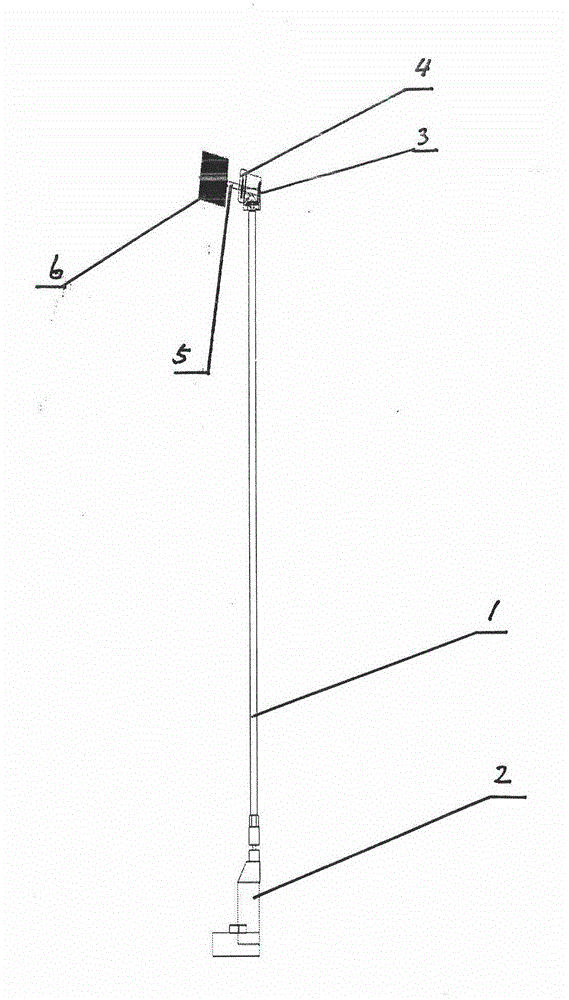

[0011] Such as Figure 1-Figure 3 As shown, the lower end of the transmission insulating rod 1 of the silicone rubber insulator live cleaner is connected to the hand-held electric drill 2 through the occlusal structure; the upper end of the transmission insulating rod 1 is connected in turn through the bevel gear transmission assembly 3 and the flat gear transmission assembly 4 to drive two nylon transmission shafts 5, two nylon transmission shafts 5 are respectively fixed inlaid with bristles in the circumference to form the cleaning brush head 6. During use, utilize the power of the hand-held electric drill 2 to drive the cleaning brush head 6 to rotate sequentially through the bevel gear transmission assembly 3 and the flat gear transmission assembly 4. The bristles of the cleaning brush head 6 rotate and act on the dirt on the surface of the silicone rubber insulator, so as to achieve the purpose of cleaning the silicone rubber insulator. It can be seen from the above emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com