Mobile spray coating system

A technology of moving a carrier and an air supply system, applied in the direction of spraying devices, etc., can solve the problems of inability to spray, trouble spraying, and high labor intensity in the spraying production line, and achieve the effect of avoiding external interference and pollution, reducing volume, and facilitating spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

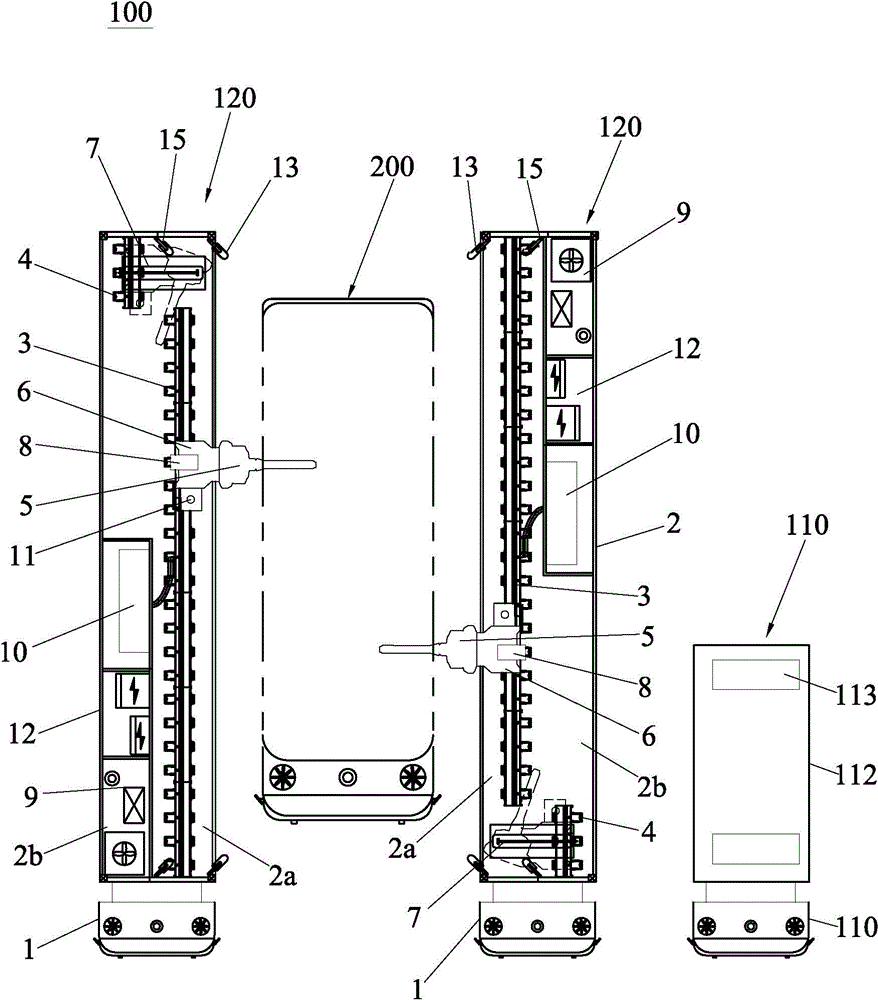

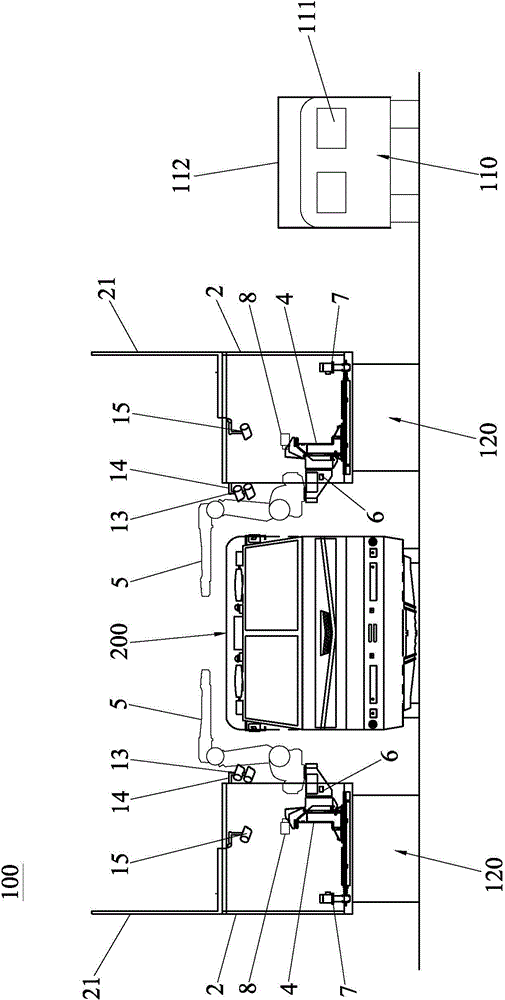

[0021] Such as figure 1 As shown, the mobile spraying system 100 of the present invention includes a mobile control unit 110 and two mobile execution units 120, and the two mobile execution units 120 are symmetrically arranged on both sides of the large workpiece 200, so that the two mobile execution units 120 can be The two sides of the large workpiece 200 are sprayed at the same time, which effectively improves the spraying efficiency.

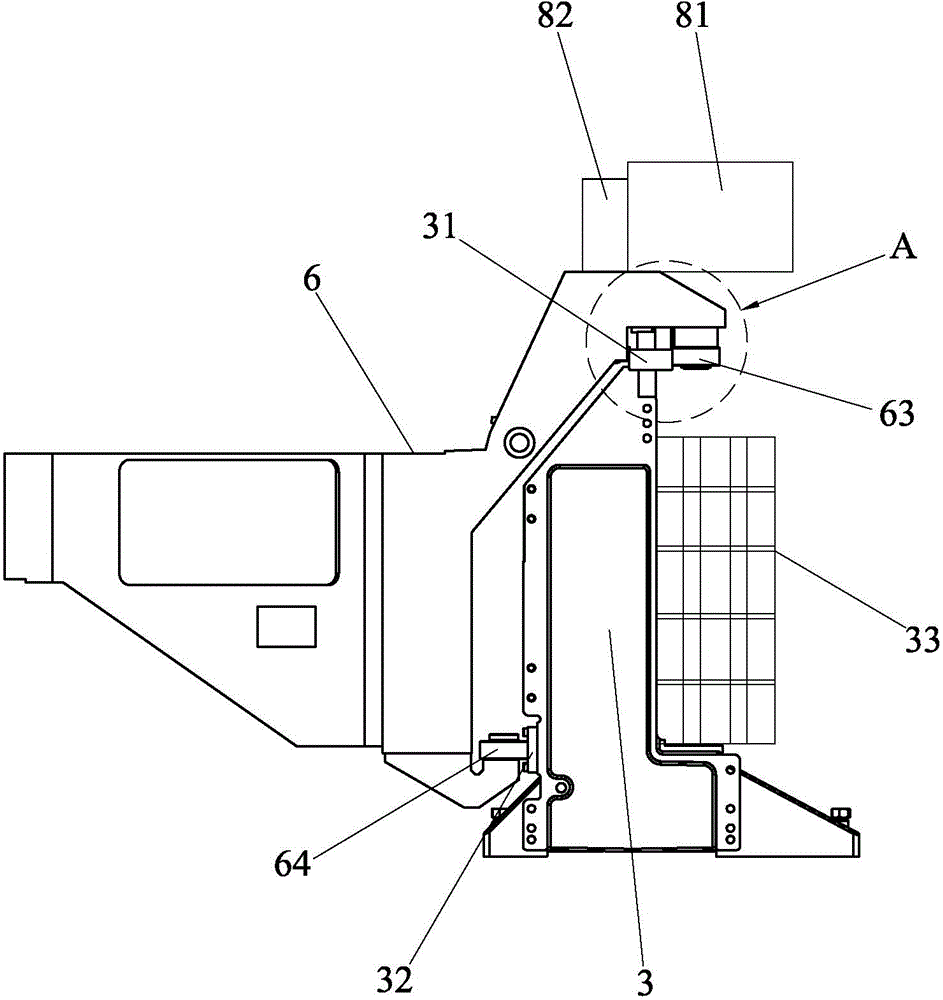

[0022] see again figure 1 , figure 2 , the mobile execution unit 120 includes a first mobile carrier 1, a first container 2, a first guide rail 3 placed in the first container 2, a second guide rail 4, a spraying robot 5, a cart 6, and a translation mechanism 7. Driving mechanism 8, air supply system 9, pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com