Decolorizing adsorbent for polyolefin purification and preparation method thereof

A polyolefin and adsorbent technology, applied in the field of polyolefin decolorizer and its preparation, can solve the problems of obvious effect of aluminum, and achieve the effects of increasing macropores, prolonging service life, and inhibiting initial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

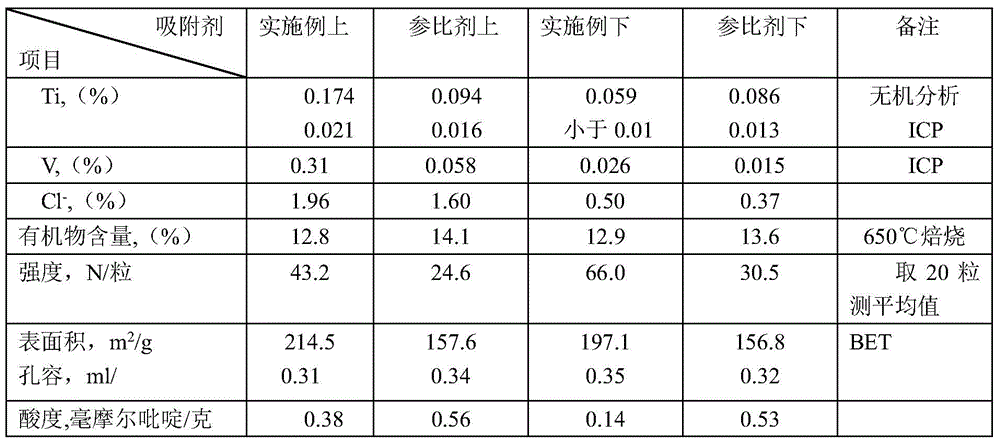

Embodiment 1

[0025] Take ×-rho alumina, add 10% (based on the weight content of the final adsorbent) silica gel and 5% metal-organic framework (MOF) promoter with a pore volume of 1.0ml / g, and then use conventional rotation to form a ball The method is to put it into a closed container after being formed, and keep it healthy for 80 hours in the presence of water vapor at 160°C. The ×-ρ alumina is basically converted into alumina monohydrate. After 5 hours, the adsorbent of the present invention was obtained.

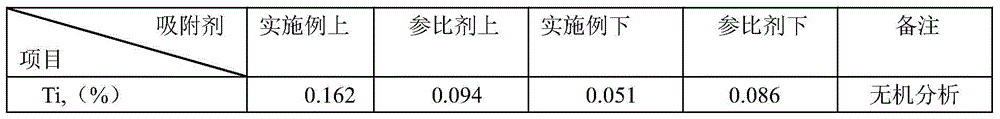

[0026]

Embodiment 2

[0028] 10% metal-organic framework (MOF) promoter was added, and other conditions were the same as in Example 1.

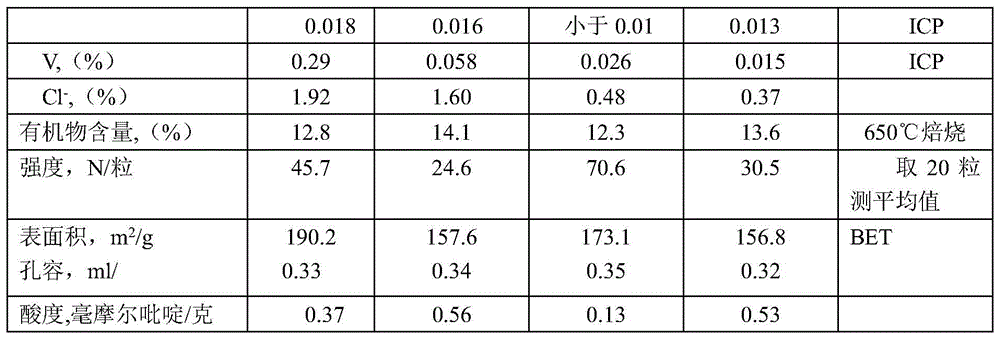

[0029]

Embodiment 3

[0031] Add 1% metal-organic framework (MOF) accelerator, and other conditions are the same as in Example 1.

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com