Near-infrared cutoff filter

A cut-off filter, near-infrared technology, applied in instruments, optical components, optics, etc., to achieve the effect of incident angle-dependent suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] Hereinafter, the near-infrared cut filter of the present invention will be described with reference to the drawings.

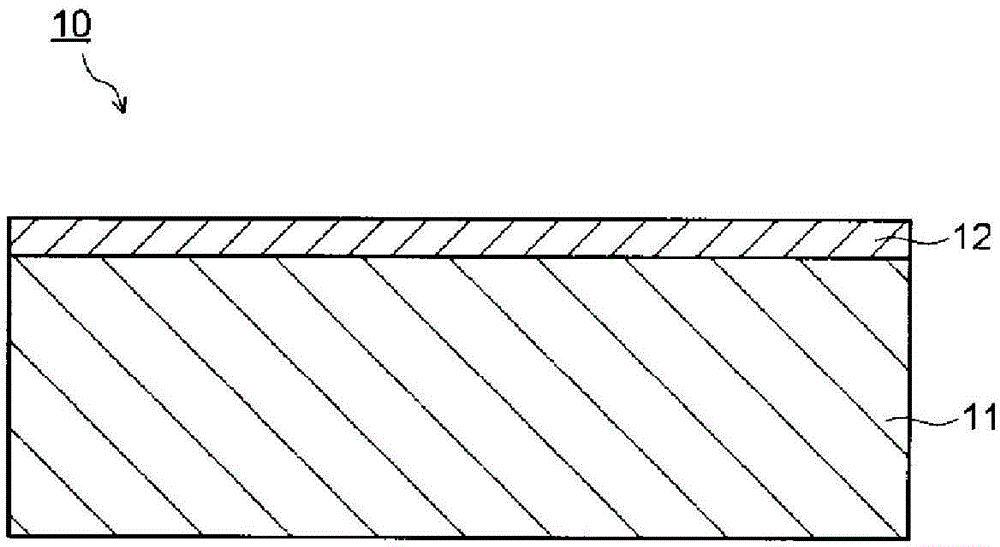

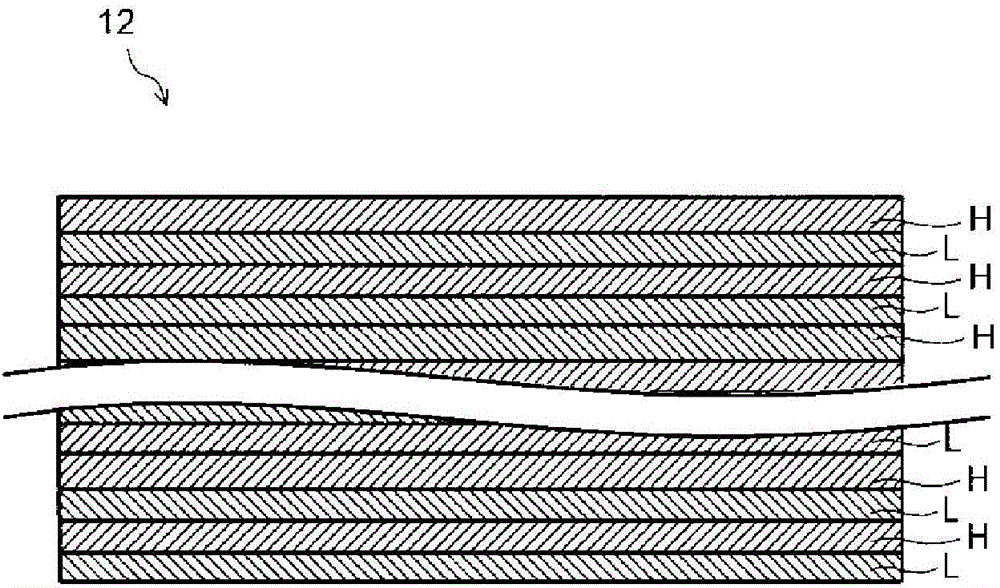

[0045] figure 1 It is a cross-sectional configuration diagram of a near-infrared cut filter 10 (hereinafter, IRCF 10) according to the embodiment. Such as figure 1 As shown, the IRCF 10 includes a transparent substrate 11 and an optical multilayer film 12 provided on at least one main surface of the transparent substrate 11. It should be noted that the optical multilayer film 12 may be provided on one main surface of the transparent substrate 11 or may be separately provided on each main surface of the transparent substrate 11.

[0046] (Transparent substrate 11)

[0047] The material of the transparent substrate 11 is not particularly limited as long as it can transmit at least light in the visible wavelength region. Examples of materials for the transparent substrate 11 include crystals such as glass, crystal, lithium niobate, and sapphire, and poly(ethyle...

Embodiment 1~4

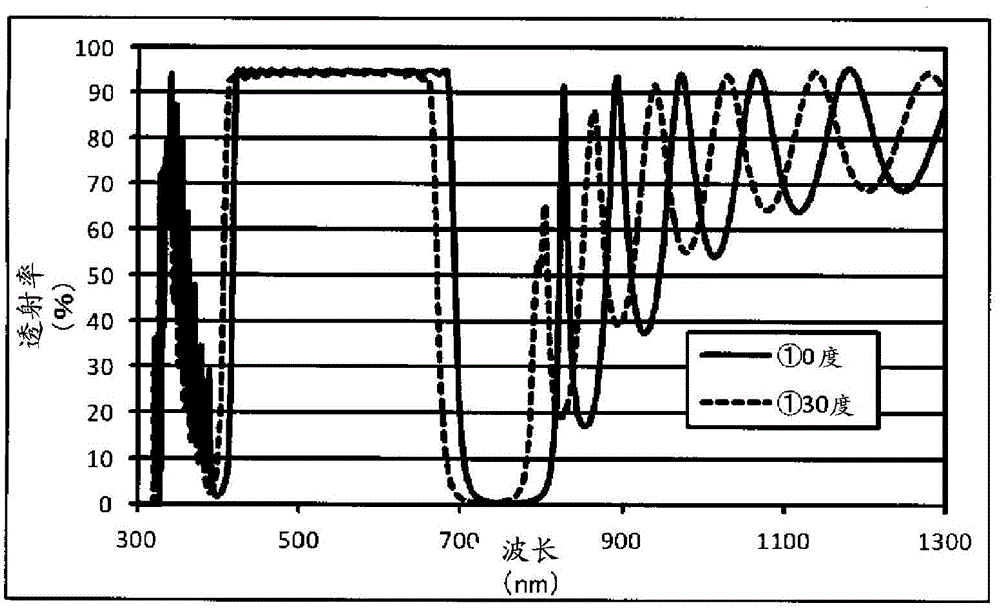

[0149] First, Examples 1 to 4 will be described. In Examples 1 to 4, titanium oxide (TiO 2 ) As the material of the high refractive index film, silicon oxide (SiO 2 ) As a material for low refractive index films. It should be noted that titanium oxide (TiO 2 ) The refractive index at a wavelength of 500nm is 2.47, making silicon oxide (SiO 2 ) The refractive index at a wavelength of 500nm is 1.48, which simulates the spectral characteristics. Below, the film conditions of Examples 1 to 4 are shown in Tables 1 to 4, and the simulation results of Examples 1 to 4 are shown in Figure 6-9 . In addition, the "film thickness" in Tables 1 to 4 is the physical film thickness. In addition, the "value of the coefficient" is a coefficient indicating that the physical film thickness is several times the QWOT.

Embodiment 1

[0151] [Table 1]

[0152] Number of layers

Membrane material

Film thickness d[nm]

The value of the coefficient

Number of layers

Membrane material

Film thickness d[nm]

The value of the coefficient

1

TiO 2

106.18

2.0981168

28

SiO 2

46.10

0.5458240

2

SiO 2

83.64

0.9902976

29

TiO 2

100.77

1.9912152

3

TiO 2

12.68

0.2505568

30

SiO 2

27.77

0.3287968

4

SiO 2

41.87

0.4957408

31

TiO 2

15.92

0.3145792

5

TiO 2

77.08

1.5231008

32

SiO 2

43.47

0.5146848

6

SiO 2

42.00

0.4972800

33

TiO 2

100.99

1.9955624

7

TiO 2

22.14

0.4374864

34

SiO 2

31.26

0.3701184

8

SiO 2

43.76

0.5181184

35

TiO 2

15.13

0.2989688

9

TiO 2

79.74

1.5756624

36

SiO 2

41.80

0.4949120

10

SiO 2

33.03

0.3910752

37

TiO 2

100.29

1.9817304

11

TiO 2

24.18

0.4777968

38

SiO 2

32.90

0.3895360

12

SiO 2

45.71

0.5412064

39

TiO 2

14.89

0.2942264

13

TiO 2

83.08

1.6416608

40

SiO 2

41.68

0.4934912

14

SiO 2

27.51

0.3257184

41

TiO 2

100.98

1.9953648

15

TiO 2

24.45

0.4831320

42

SiO 2

34.72

0.411084...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com