A platform unit for combined sensing of pressure, temperature and humidity

A platform and pressure technology, applied in the field of platform units, can solve problems such as pressure, temperature and humidity unmet needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Example 1: Sensing temperature and humidity

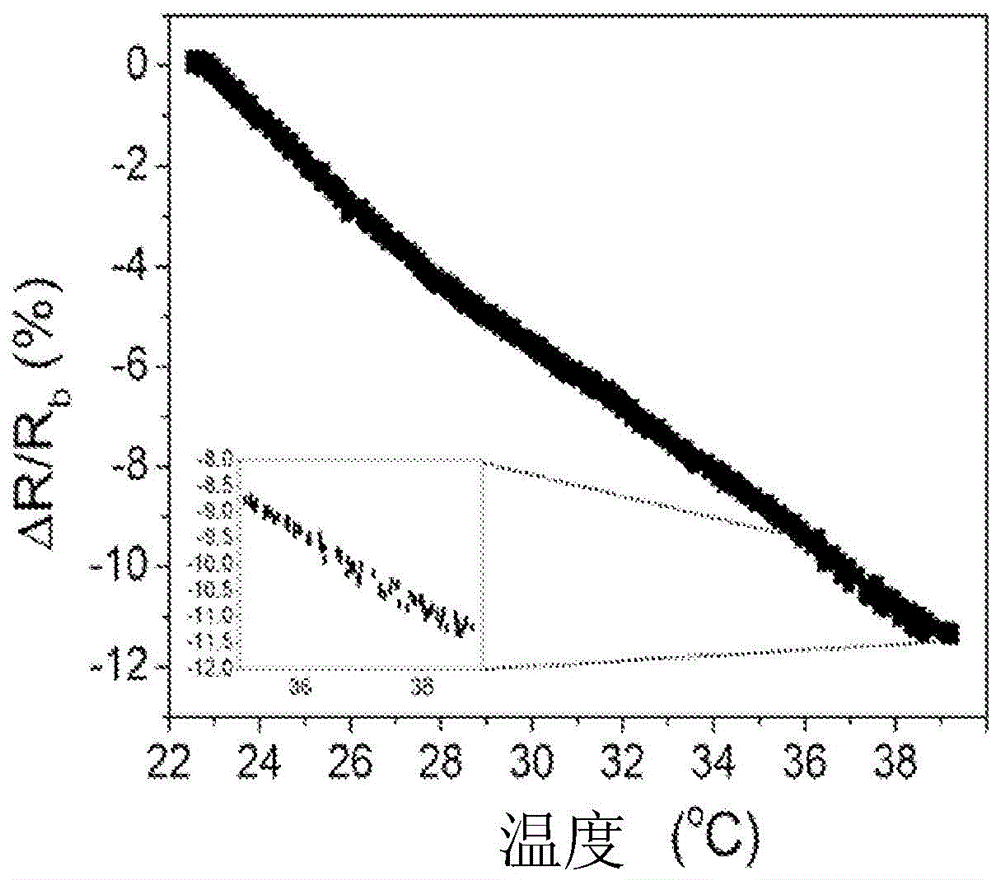

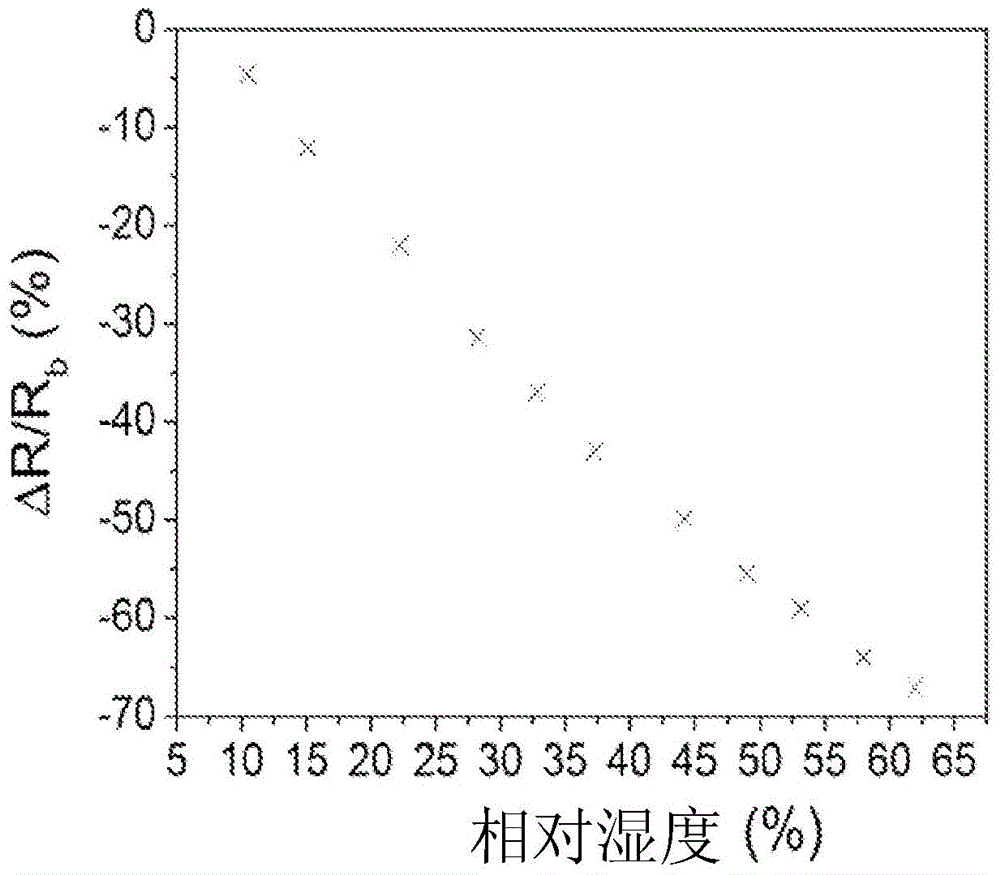

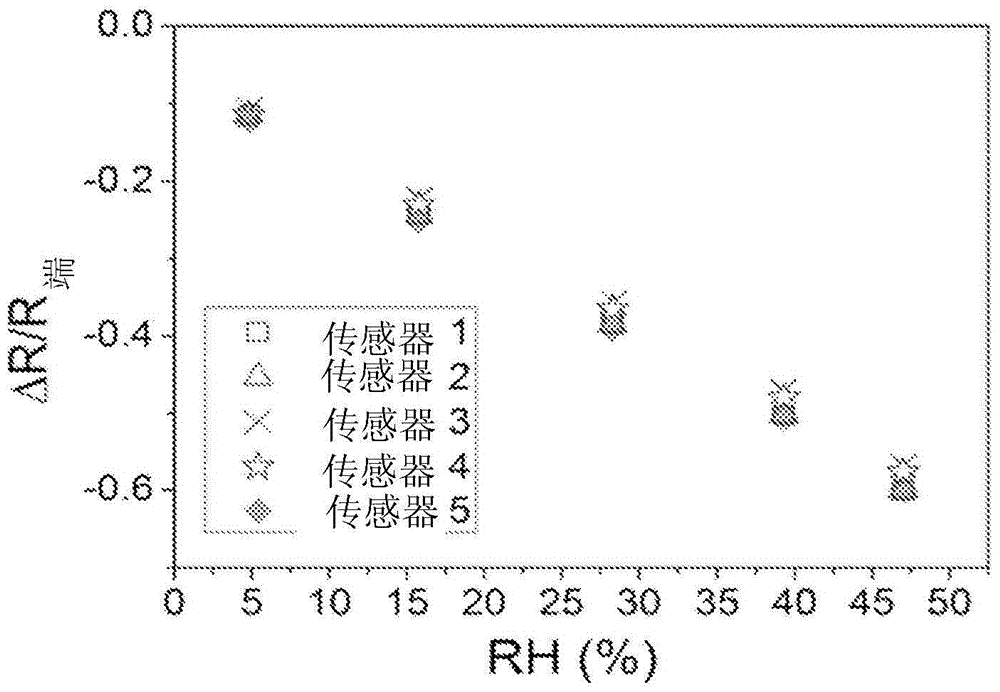

[0139] Examine the possibility of integrating temperature and humidity sensing capabilities within an MCNP-based touch platform. For this purpose, a nitro-4-trifluoro-methylbenzenethiol (NTMBT) MCNP sensor was placed in a vacuum chamber with a controlled environment. Change temperature or relative humidity (RH) in a stepwise fashion and monitor the corresponding ΔR / R b . Figure 1A gives the ΔR / R of the sensor at increasing temperature b . ΔR / R b It is linear and decreases by 1% for every 1.33°C increase in temperature, which makes this sensor sensitive enough to monitor temperature fluctuations in the surrounding environment. Zoom-in in the temperature regime of 35–39 °C shows that the sensitivity of the NTMBT-MCNP-based sensor is high enough to act as a human body thermometer capable of accurately detecting fluctuations as small as 1 °C or the presence of heat sources near artificial or electronic skin without touch...

Embodiment 2

[0141] Example 2: Effects of Stretching and Bending on Flexible MCNP Sensors

[0142] Examination of gold coated with 3-ethoxythiophenol ligand (ETP-MCNP) on flexible polyethylene terephthalate (PET) substrates by three-point bending test under bending and tensile conditions Nanoparticle pressure sensors. All tests were performed at a room temperature of 20°C ± 1°C and a relative humidity (RH) level of 50% ± 3%. Figure 3F-3G Loaded and unloaded curves of the ETP-MCNP strain sensor on PET substrate are given. The relative resistance response (ΔR / R b , where R b is the baseline resistance with no load applied to the sensor, and ΔR is the R b and the resistance change when a load is applied to the sensor). After stepwise changing the bending level of the PET substrate, the positive or negative change in resistance was linear. When the ETP-MCNP film was placed on the top side of the PET substrate, bending the substrate resulted in the compression of the ETP-MCNP film, whi...

Embodiment 3

[0147] Example 3: Effect of Substrate on Morphology of MCNP Layers and on Related Sensing Properties

[0148] The relative response of the sensors is proportional to the offset (for a particular bending facility). Therefore, the response of the flexible sensor increases when a larger offset is introduced. A certain load sensitivity range is required since large deflections can lead to irreversible changes both to the flexible substrate as well as to the MCNP layer. In this way, high loads can be measured using a thick substrate with a high Young's modulus, and small loads can be measured using a thin substrate with a low Young's modulus.

[0149] The relationship between the properties of the substrate and the MCNP-based load sensor was explored by depositing ETP-MCNP films on the following substrates: (i) substrates with similar composition (e.g., same polymer) but different thicknesses; and (ii) ) substrates of different composition (eg, different polymers) but similar t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com