Method for realizing two kinds of luster, plastic casing and terminal

A plastic shell and glossy technology, which is applied to the parts of cabinets/cabinets/drawers, the process for producing decorative surface effects, decorative arts, etc., can solve the problem of glossiness and single color, glossy and matte surfaces To achieve a better texture and sharper contrast than other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

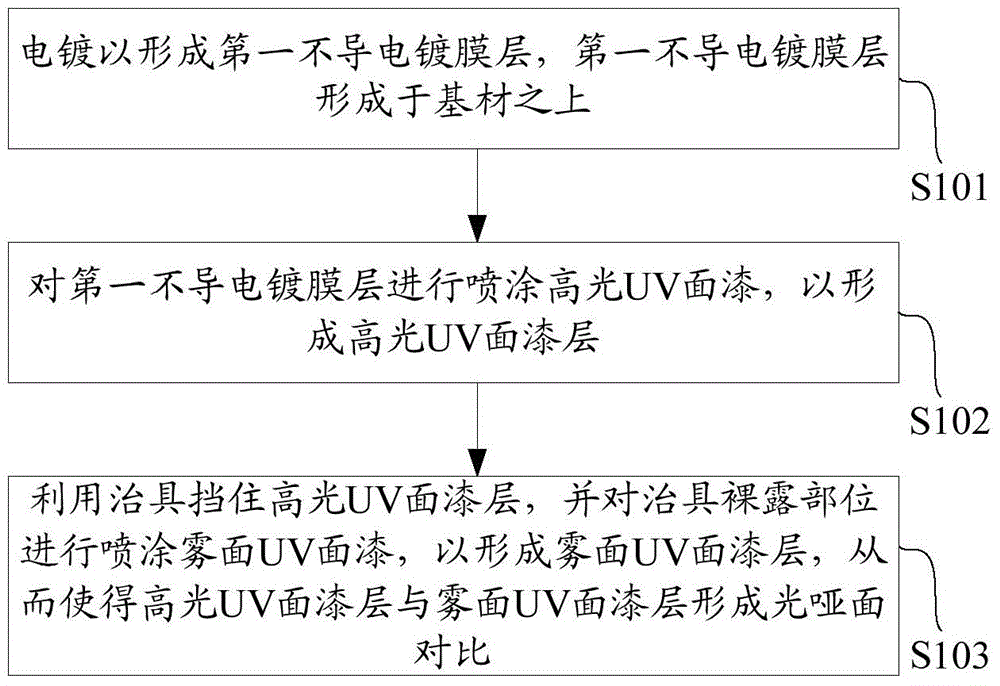

[0029] like figure 1 as shown, figure 1 It is a schematic flow chart of the first embodiment of the method for realizing double gloss in the present invention. The method can realize a smooth and matte surface of the product, making the product texture better.

[0030] The method includes the following steps:

[0031] Step S101 : electroplating to form a first non-conductive coating layer, and the first non-conductive coating layer is formed on the substrate.

[0032] In step S101, it can be carried out by water plating or NCVM process. The NCVM process is preferably used in this embodiment. The NCVM process can make a metal appearance effect and beautify the surface of the workpiece, and the formed first non-conductive The thickness of the coating layer is less than 0.3 μm, such as 0.1 μm or 0.2 μm. The first non-conductive coating layer has no c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com