Electric heating element

An electric heating element, a heating element technology, applied in the direction of the shape of the heating element, etc., can solve the problems of increasing the outer diameter and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

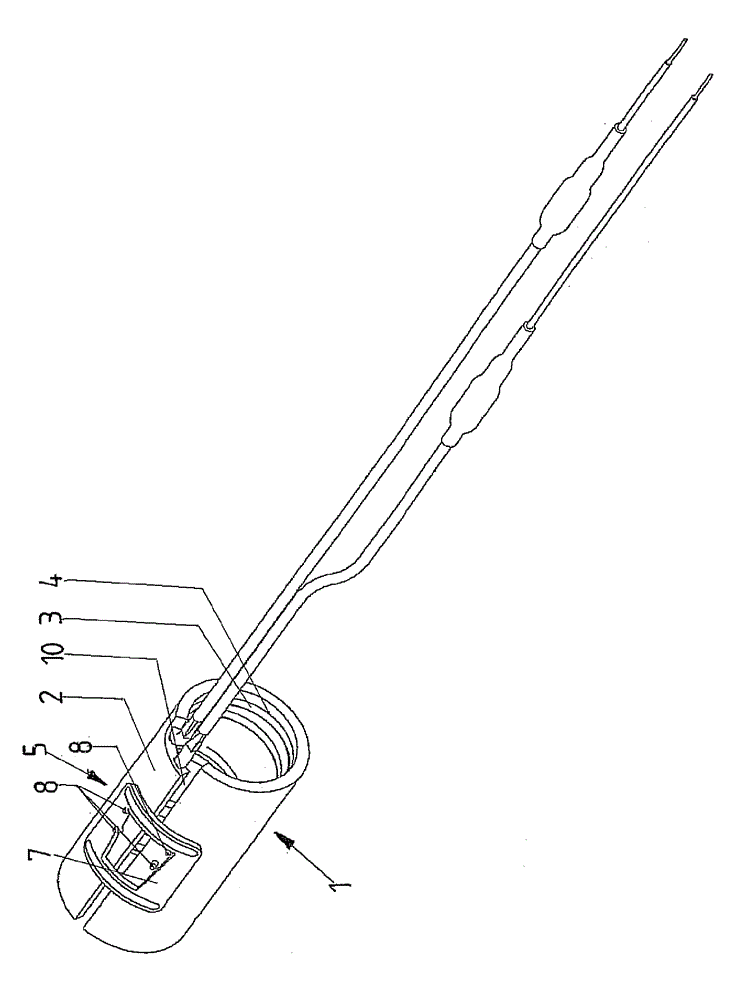

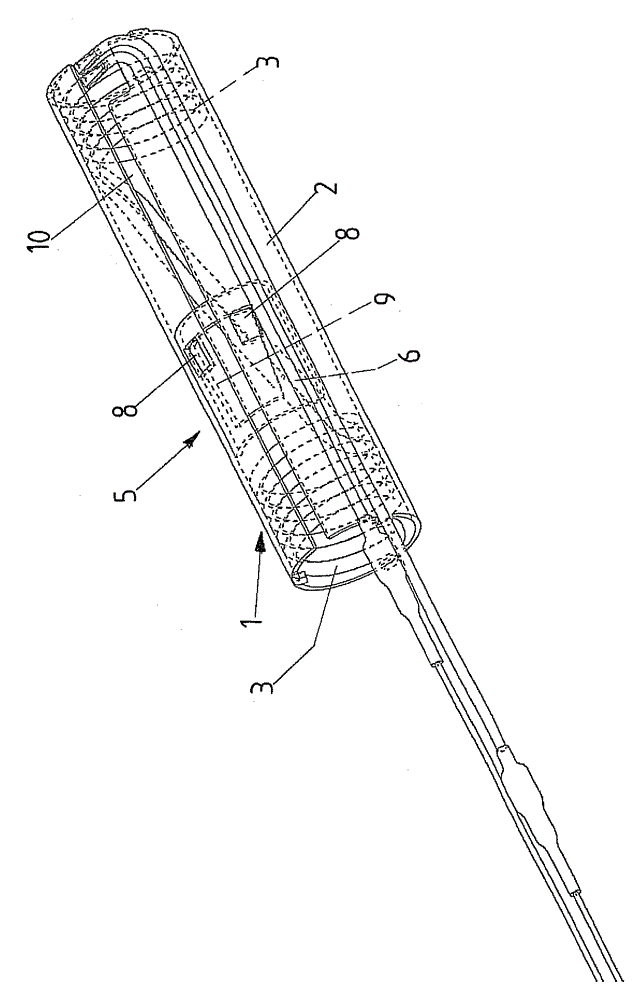

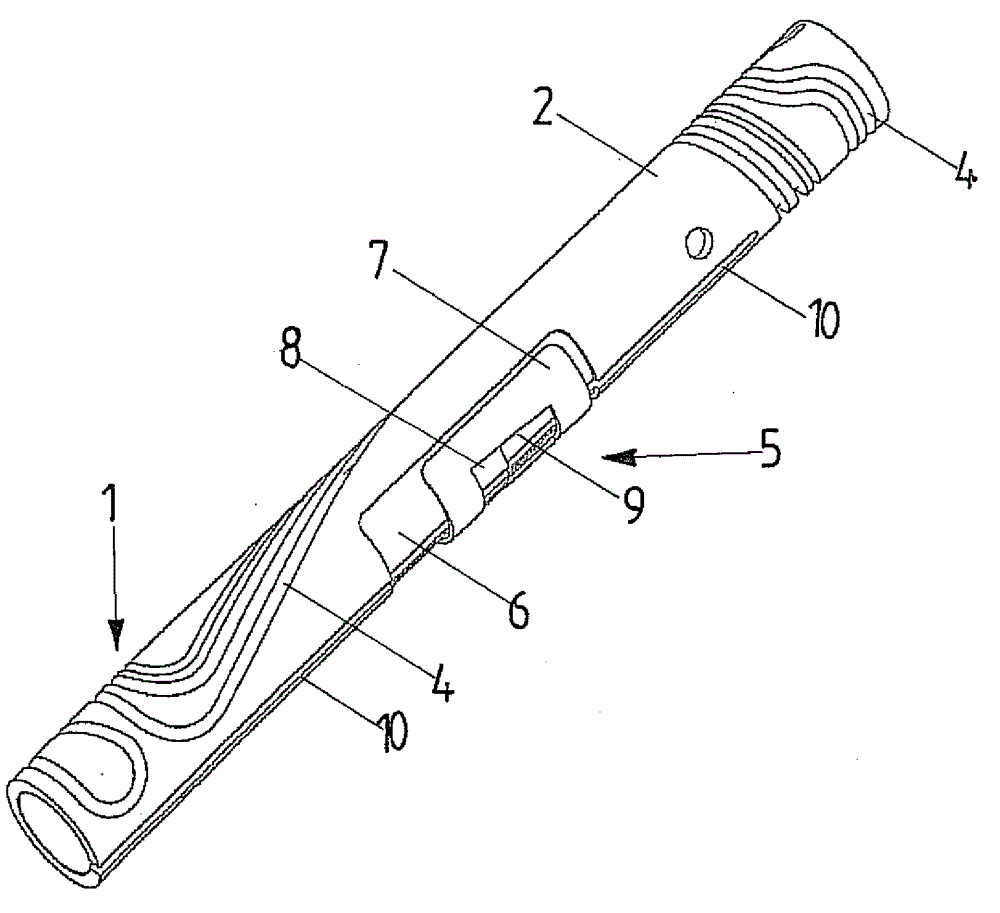

[0038] according to figure 1 The embodiment of FIG. 1 shows a heating element according to the invention having a heating body arranged externally on the shell of the respective heating body and an external wedge latch. Figure 7 and 8 An embodiment of a heating element is shown with a heating body arranged inside the housing and an external wedge-shaped latch. according to eg Figures 1 to 6 In the above-mentioned embodiment, the heating body is embedded in the material of the shell tube, and in accordance with Figure 11 and 12 The same is true in the embodiment of , but the heating body is arranged inside the shell, while the wedge-shaped latch is arranged outside. in accordance with Figure 5 and 6 In an embodiment, the heating body is embedded in the shell. in accordance with Figure 7 and8 with in accordance with Figure 9 and 10 In the embodiment, the heating body is installed on the inner side of the shell of the heating element, while the wedge-shaped latch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com