Watertight Sealed Electrical Connector Assemblies

A technology for electrical connectors and waterproof sealing, which is applied to parts, connections, electrical components, etc. of connecting devices, can solve problems such as poor waterproof and sealing performance, and achieve the effect of solving poor waterproof and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

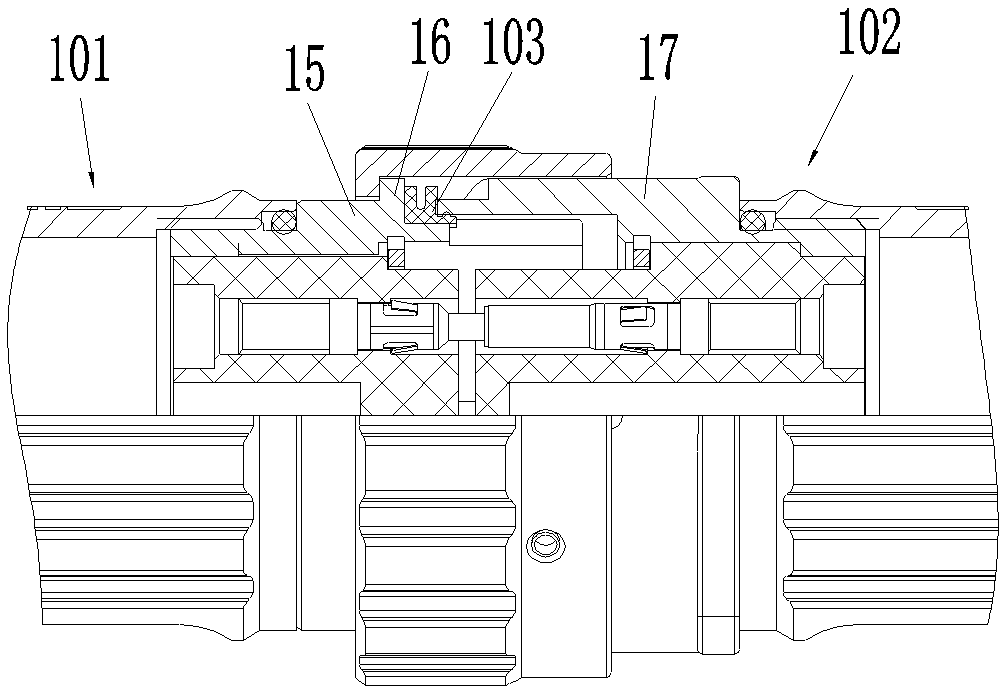

[0015] Embodiments of waterproof sealed electrical connector assemblies, such as Figure 1-3 As shown, the waterproof and sealed electrical connector assembly includes a plug 101 and a socket 102, each of which has a front end as a plugging end.

[0016] The plug 101 includes a plug housing 15. The front part of the plug housing is provided with an insertion section for being inserted into the socket housing and a sealing baffle 16 is provided at the rear end of the insertion section. The plug housing 15 is also provided with a sealing edge. Ring groove, the sealing ring groove is located at the front side of the sealing baffle and the sealing rubber ring 103 is installed therein, and the lower part of the front side of the sealing baffle 16 constitutes the rear side wall of the sealing ring groove.

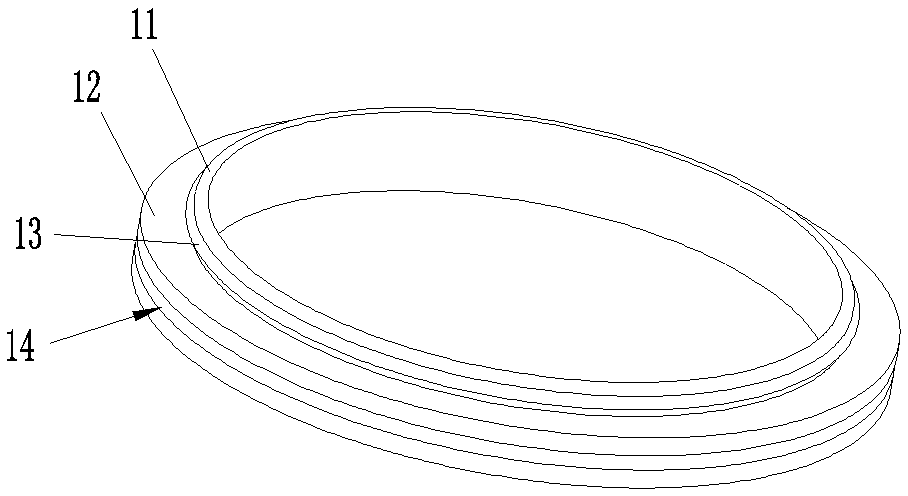

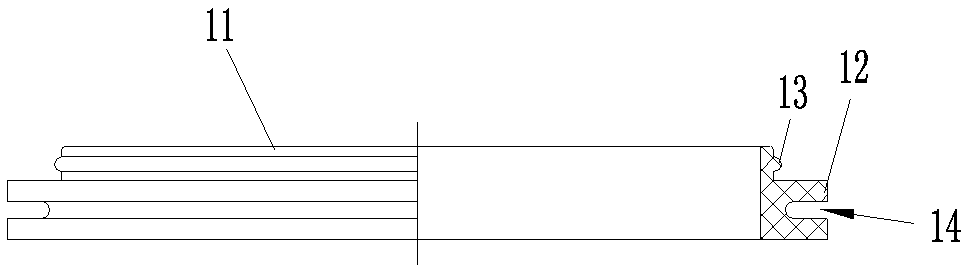

[0017] The sealing rubber ring 103 includes a radial sealing part 11 and an end face sealing part 12 , wherein the radial sealing part 11 and the end face sealing part 12 are of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com