Contactor wire terminal component structure

A component structure and contactor technology, which is applied in the direction of relays, electrical components, electromagnetic relays, etc., can solve the problems of inconvenient wiring of static contacts, difficulty in accurately controlling the range of wiring frames, troublesome wiring of static contacts, etc., and achieve simple structure , low cost, convenient wiring and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

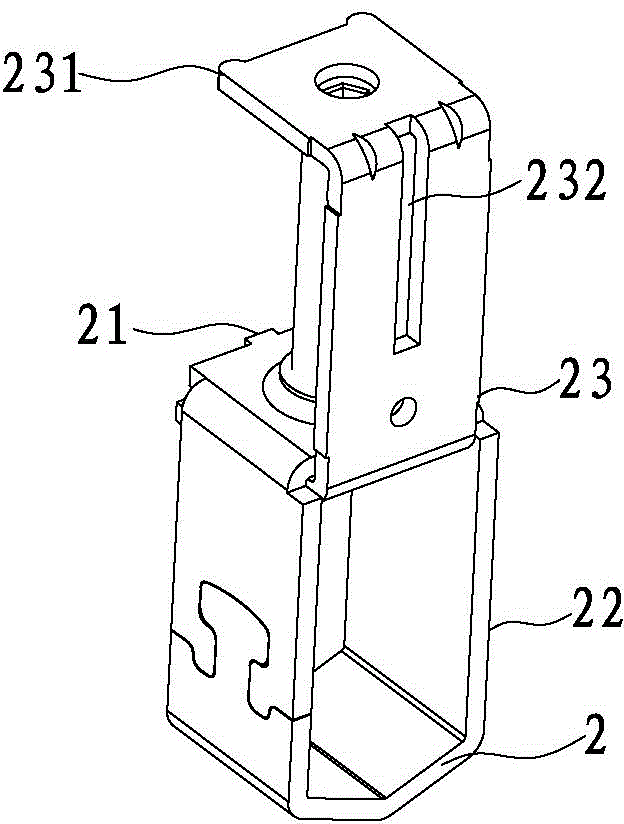

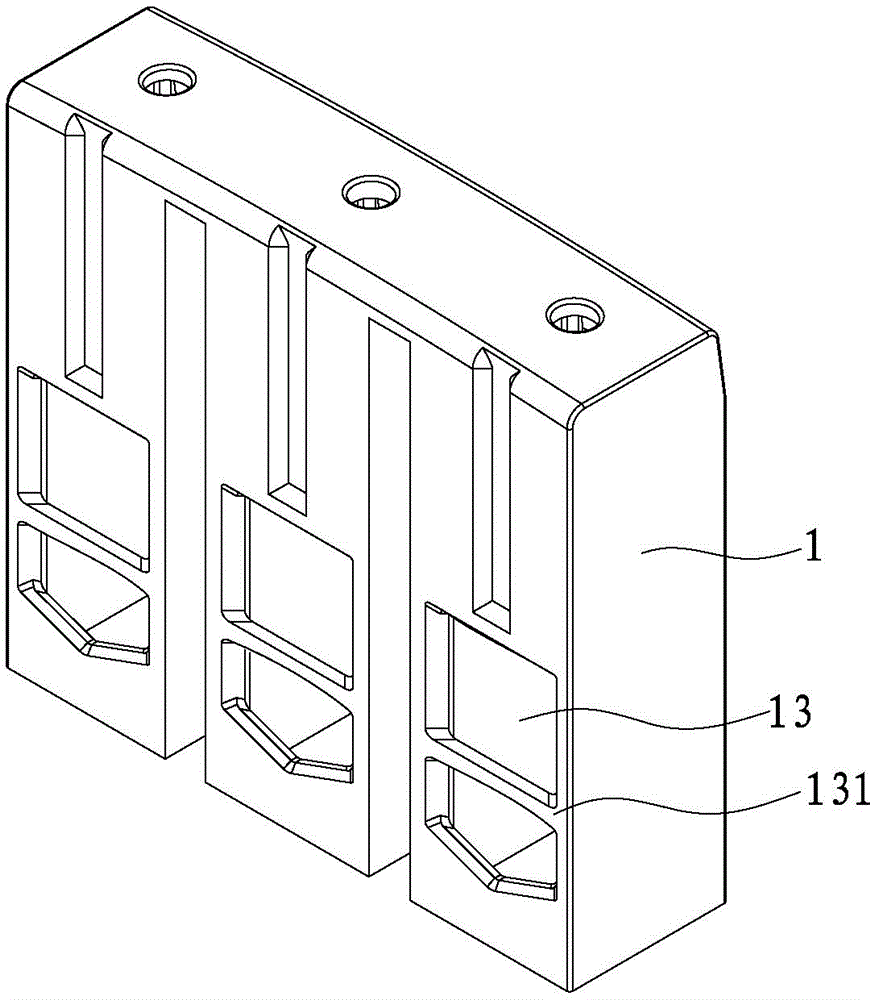

[0049] refer to Figure 1 to Figure 13 As shown, a contactor terminal assembly structure disclosed by the present invention is installed on the contactor body, including a terminal module 1 and a terminal frame 2 .

[0050] Terminal block module 1 is installed on the body shell 3, such as Figure 10 and Figure 13 As shown, the wiring terminal module 1 forms at least one installation cavity 11. In this embodiment, there are three installation cavities 11, one end of the installation cavity 11 is closed, and the other end is open.

[0051] One side wall of the installation cavity 11 of the terminal module 1 is provided with a perforation 12 for the static contact 4 to pass through, and a receiving surface for the static contact 4 is provided on the perforation 12 to reduce the possibility of rotation of the terminal frame 2 after it is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com