Vertical winding machine for transformers with amorphous alloy three-dimensional wound iron cores

A technology of three-dimensional winding core and vertical winding machine, which is applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc. Iron core electromagnetic performance and other problems, to achieve the effect of eliminating stress, improving winding efficiency, and reducing the turnover process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

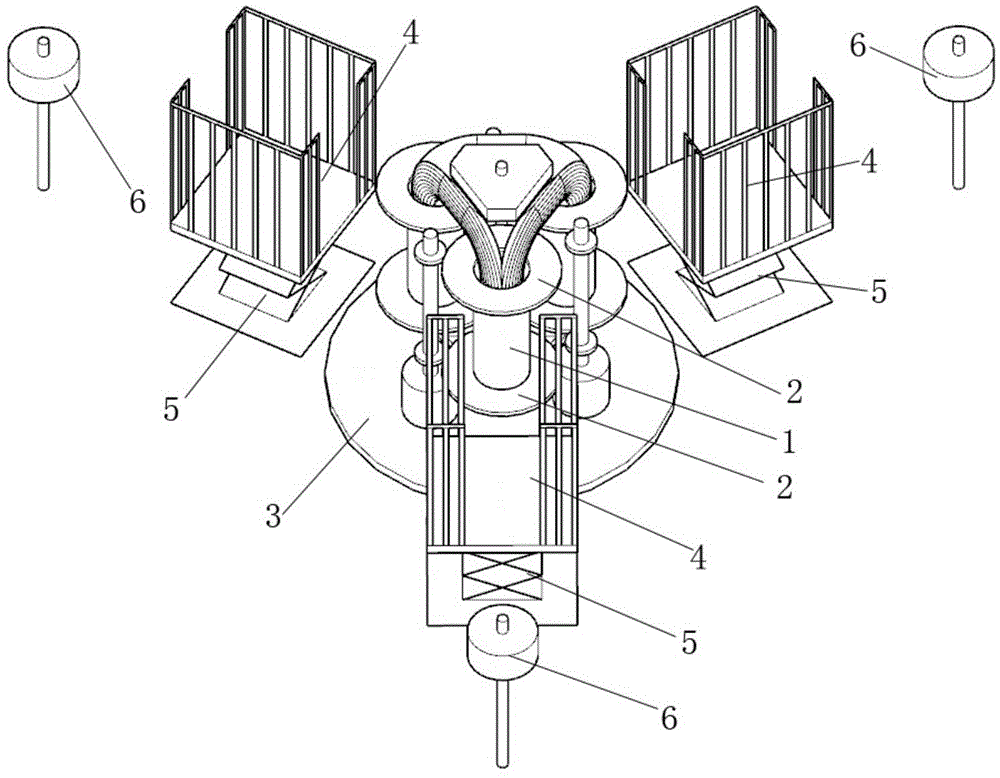

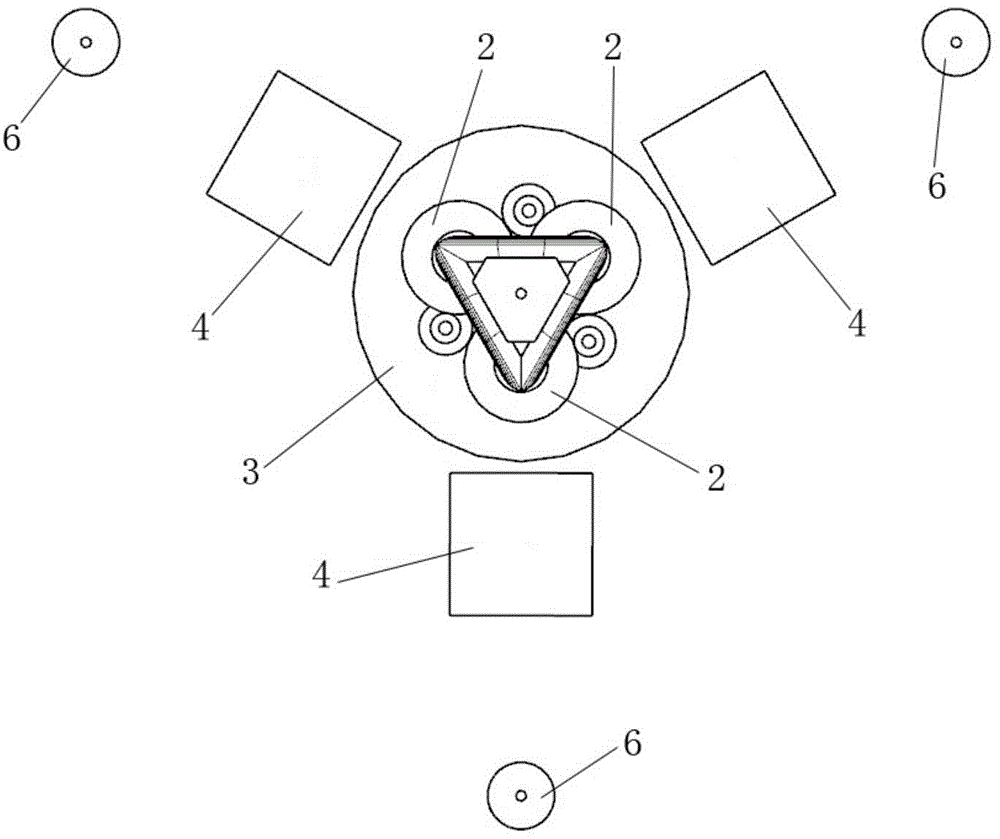

[0014] Such as figure 1 , figure 2 As shown, the present invention includes a coil mold 1, a rotating gear 2, a fixed platform 3, a workbench 4, an elevator 5, and a wire wheel 6.

[0015] The main function of the coil mold 1 is to support the binding force of the wire when the coil is wound, avoiding the direct force on the iron core, so as to avoid the decrease of the electromagnetic performance of the iron core due to the binding stress of the wire during the winding process. The coil mold 1 can be a rigid detachable mold 1, or a specially designed insulating part that will eventually be a part of the transformer.

[0016] There are 6 rotating gears 2 in the present invention, two coils for each phase, distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com