Automatic paper output device based on test strip

A test strip and automatic technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of high packaging cost of test strips, easy cross-contamination of test strips, inconvenient access to test strips, etc., and achieve the effect of preventing cross-contamination and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

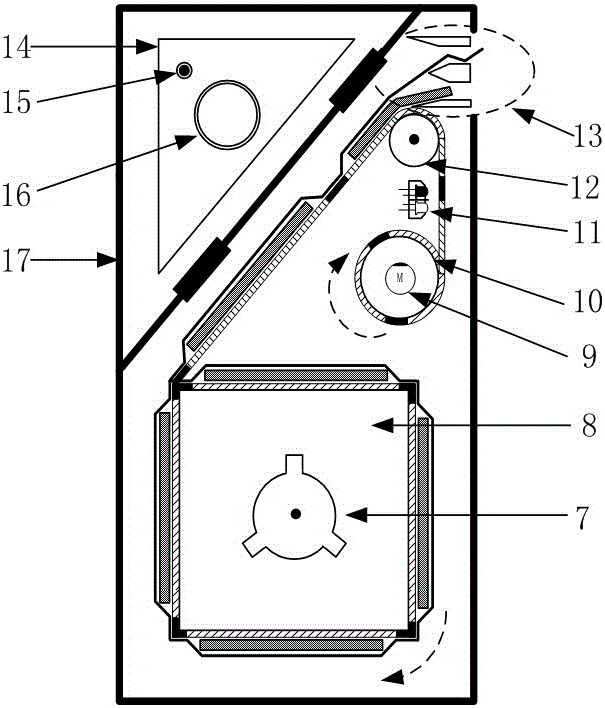

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] like image 3 As shown, the housing 17 of the device of the present invention is divided into two chambers, one of which is equipped with a special-shaped rotating shaft 7, a test paper disc 8, a motor 9, a nylon belt guide plate 10, a guide wheel 12, a mark detection device 11 and Separating the guide mechanism 13, the test paper disc 8 with a special-shaped hole in the center is set on the special-shaped rotating shaft 7, and the special-shaped hole is matched with the special-shaped rotating shaft 7, and the shape of the special-shaped hole is as follows: image 3 As shown, three bumps are arranged at equal intervals along the peripheral surface.

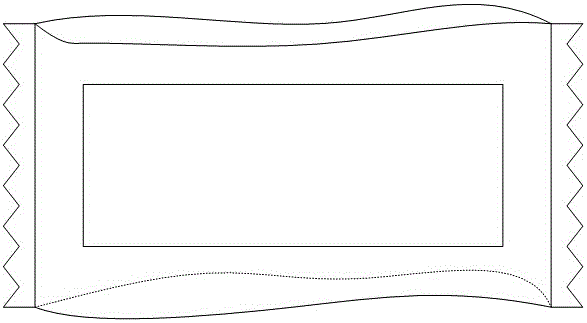

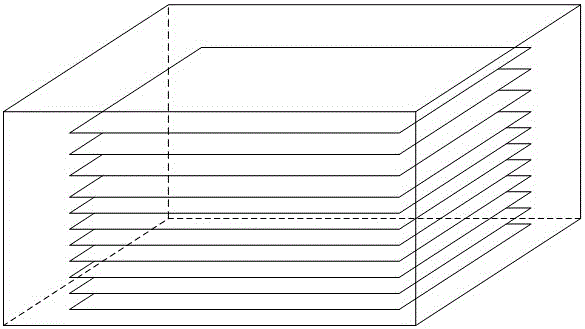

[0026] One end of the test paper strip 1 is wound on the test paper disc 8, and the other end of the test paper strip 1 is wound around the guide wheel 12 and then wound on the nylon belt guide disc 10, and the nylon b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com