Lever type pressure sensor

A pressure sensor and lever-type technology, applied in the field of sensors, can solve the problems of poor sensing accuracy, sensor corrosion, and inability to accurately sense pressure, and achieve the effect of overcoming poor detection accuracy and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following description, for the purpose of illustration rather than limitation, specific details such as specific structures are provided only for the purpose of allowing those skilled in the art to thoroughly understand the present invention. However, it should be clear to those skilled in the art that the present invention can also be implemented in other embodiments without these specific details. In other cases, detailed descriptions of well-known devices, circuits, and methods are omitted to avoid unnecessary details obscuring the focus of the present invention.

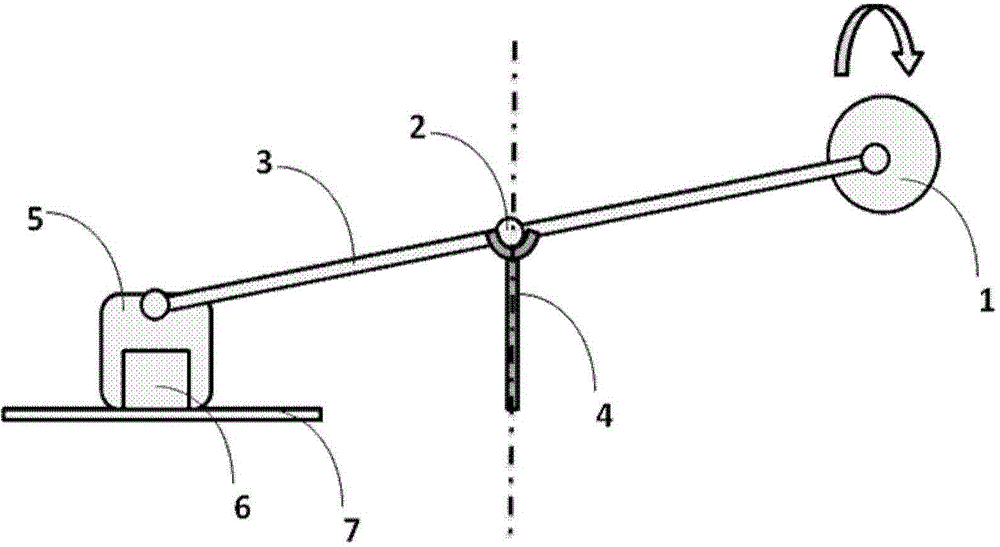

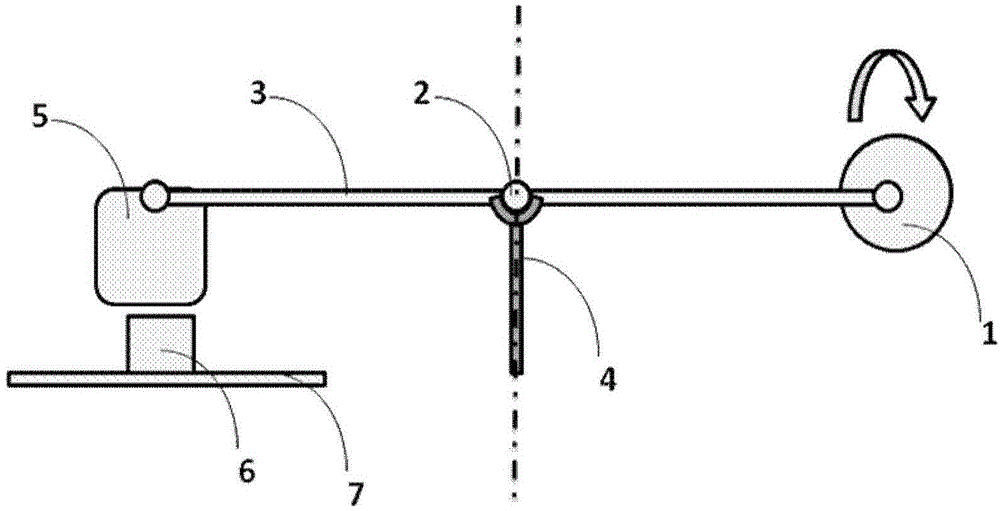

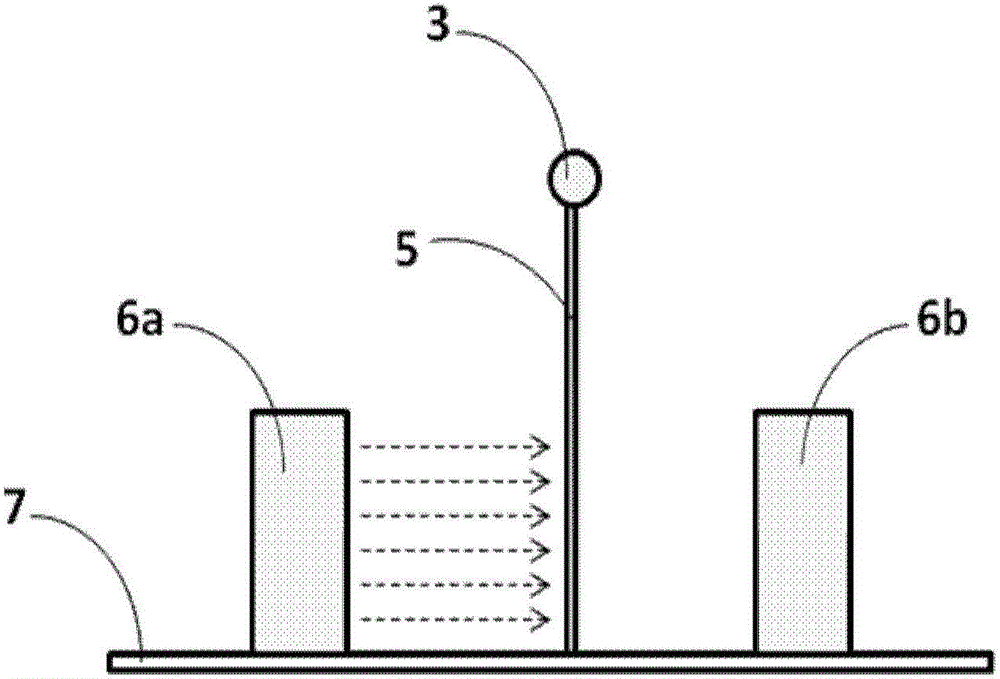

[0021] figure 1 The schematic diagram of the structure of the lever-type pressure sensor of the present invention is shown. As shown in the figure, the lever-type pressure sensor includes: a lever 3; a pressure receiving member connected to the first end of the lever 3 and configured to drive the first end of the lever 3 to move when pressure is applied; And a displacement sensing component, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com