Electric control type pressure reduction water conveying valve

A water delivery valve and electronic control technology, applied in valve details, diaphragm valves, safety valves, etc., can solve problems such as affecting the water flow pressure reduction effect, damage to the water flow pressure reducing valve, and large volume of the pressure reducing valve, and achieve good sealing performance. and elasticity, preventing pressure instability, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

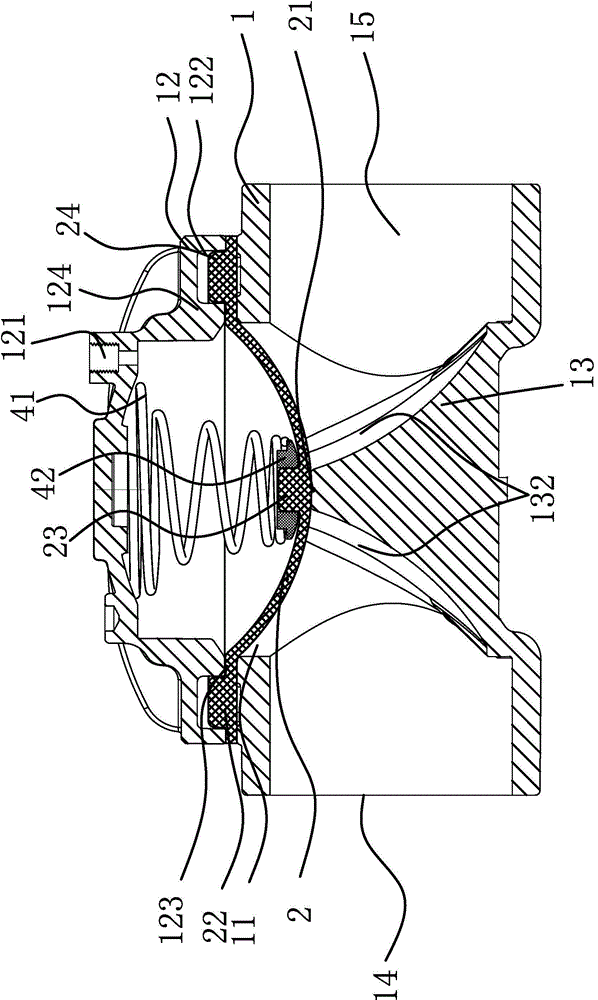

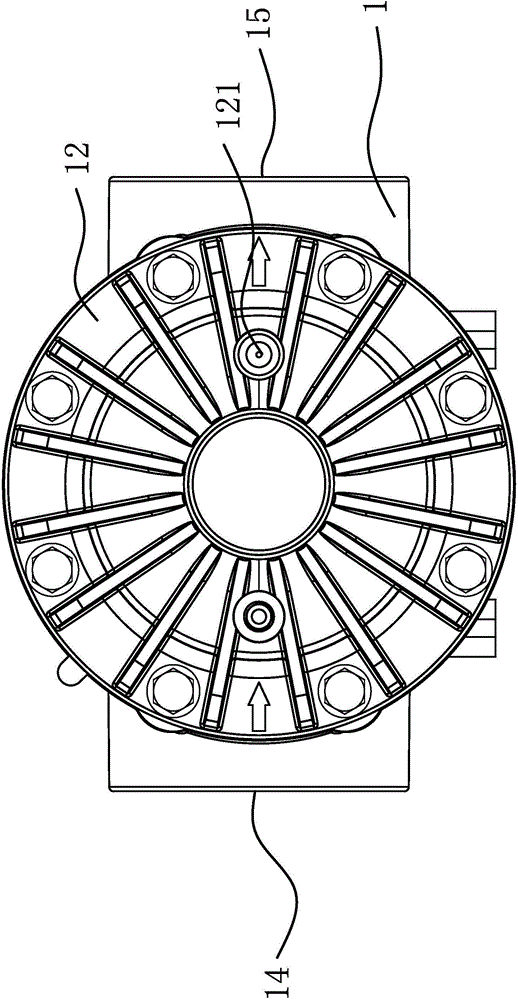

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0027] like figure 1 and figure 2 As shown, the present invention includes a valve body 1 with a cover 11 and an arched valve cover 12 installed on the cover 11, the outer edge of the cover 11 extends along the vertical axis of the cover 11 to form a cover plate 111, the valve The outer edge of the cover 12 extends along the direction perpendicular to the axis of the valve cover 12 to form a fixed part 124, which is installed on the cover plate 111, and the inner surface of the valve body 1 protrudes to form a sealing platform 13, and the sealing platform 13 is on the cover 11. Just below the valve cover 12 and the valve body 1, a cup 2 is installed. The outer edge of the cup 2 extends along the direction perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com