Acinetobacter and microbial flocculant prepared by fermenting same

A microbial flocculant, microbial flocculation technology, applied in the direction of microorganisms, microorganisms, microorganism-based methods, etc., can solve problems such as death, increased soil aluminum content, and impact on human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

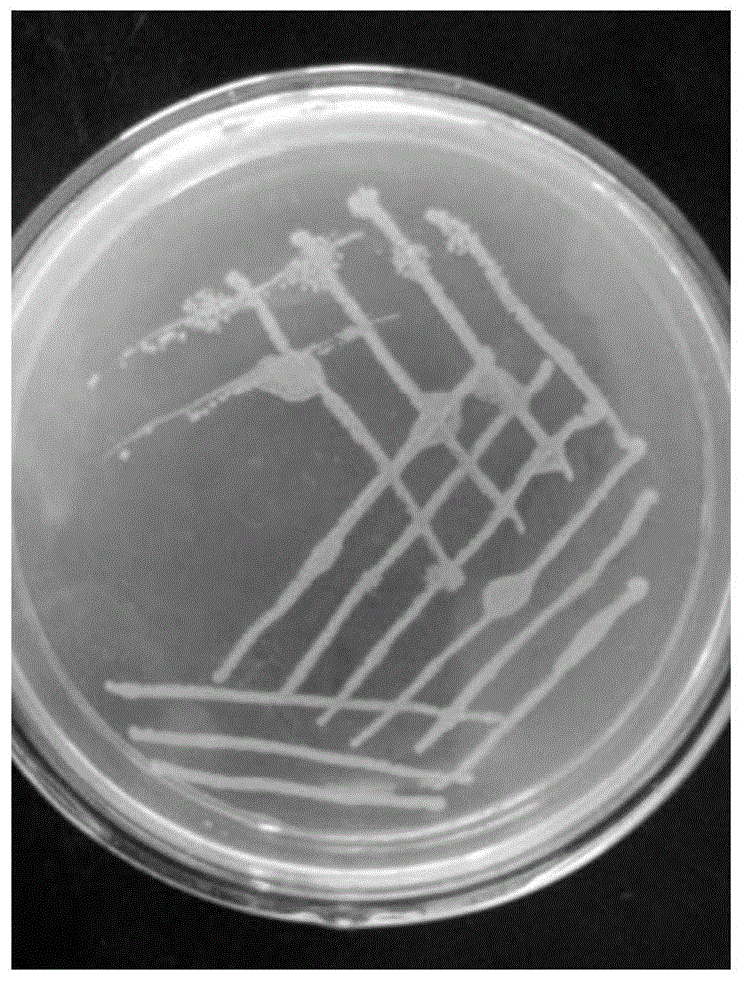

[0060] 1. Isolation and purification of Acinetobacter of the present invention

[0061] The Acinetobacter of the present invention is obtained from the waste water of Jiangsu Hanyi Molding Co., Ltd. by means of a plate streaking method.

[0062] Isolation of flocculating bacteria: inoculate the obtained wastewater into the beef extract peptone liquid medium, and incubate at a constant temperature of 37°C for 24h. Dip a small amount of bacterial solution with an inoculation needle and draw a line on the beef extract peptone agar plate, and observe the growth of the colony regularly. Then, single colonies were picked by plate streaking method, and transferred to the slant of beef extract peptone agar for storage for later use.

[0063] Screening of Acinetobacter that produces microbial flocculants: screening by the flocculation effect of kaolin suspension.

[0064] (1) Primary screening: Inoculate each single colony picked out into a large amount of fermentation medium, and cu...

Embodiment 2

[0078] Bacteria seed liquid culture: pick a small amount of bacteria from the slant of the beef extract peptone agar medium of Acinetobacter lophi FL-2, inoculate it into the beef extract peptone liquid medium, and cultivate it at a constant temperature of 37°C for 24 hours, which is the seed liquid , wherein the bacterial concentration in the seed liquid is 1.5×10 6 individual / mL.

[0079] Large amount of liquid fermentation: inoculate the seed liquid into a large amount of fermentation medium (100mL of fermentation medium in a 250mL Erlenmeyer flask) at a ratio of 3%, and cultivate at 30°C for 72h on a shaking table at 160r / min.

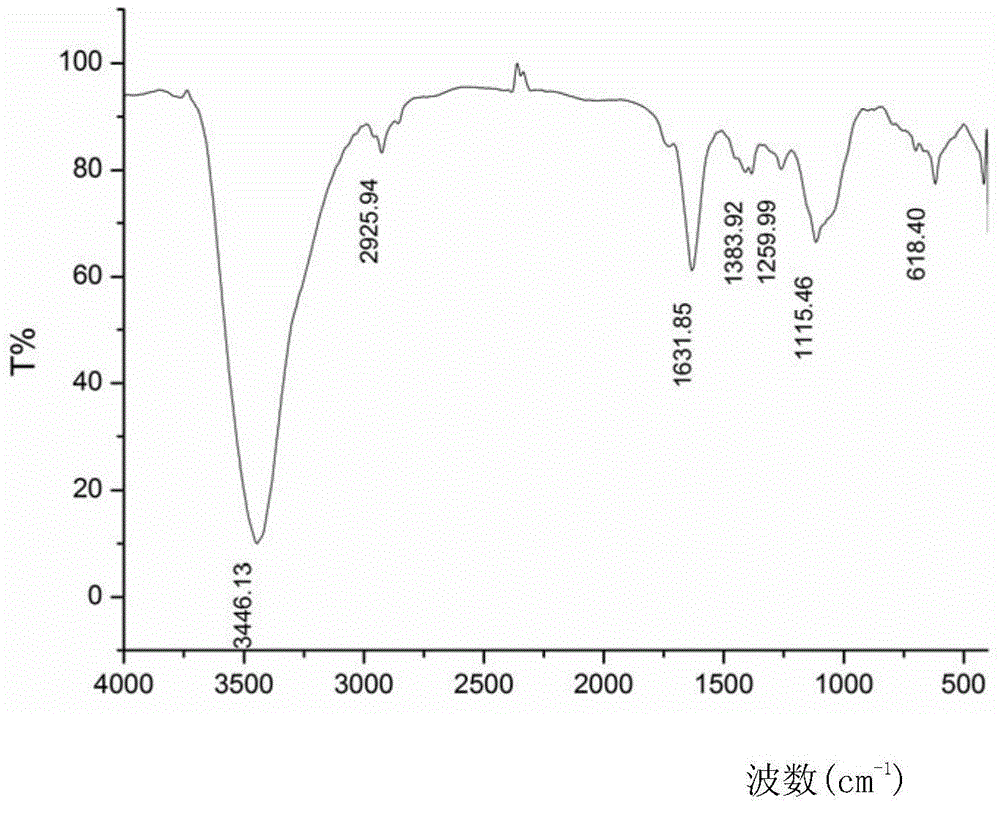

[0080] Centrifuge the fermented liquid obtained in a high-speed refrigerated centrifuge at 8000r / min for 20min at 4°C to obtain a supernatant, add twice the volume of absolute ethanol pre-cooled at 4°C to the supernatant, and let stand at 4°C Overnight, then centrifuge under the same centrifugation conditions, pour off the supernatant, dialyze the...

Embodiment 3

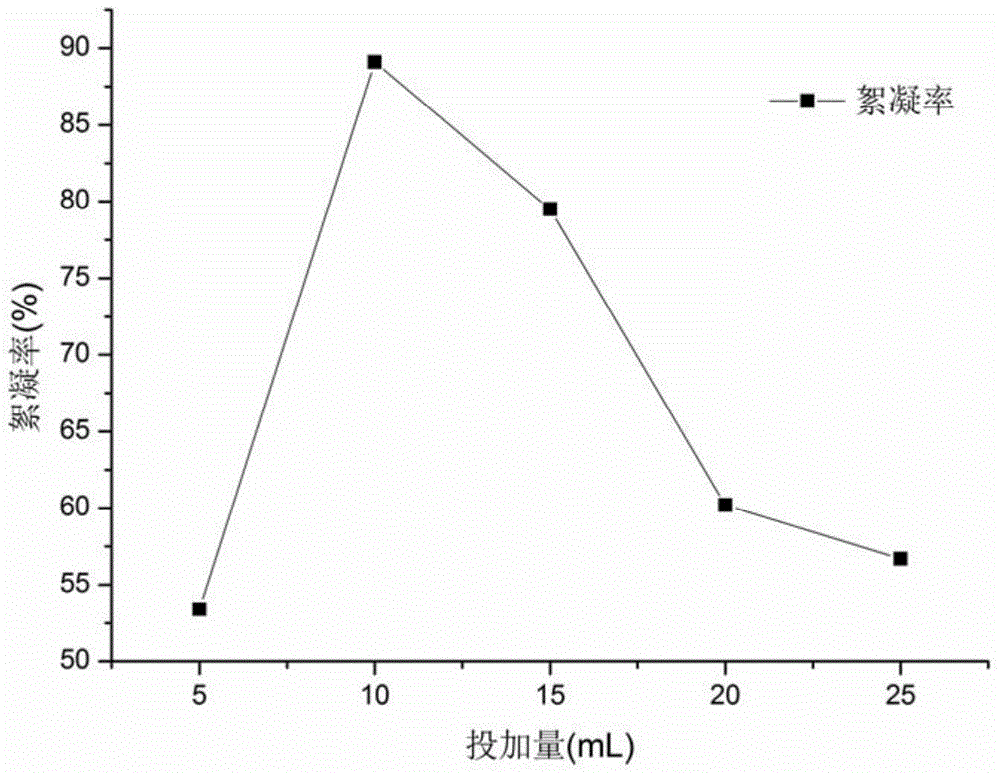

[0082] This example provides the flocculation experiment of the microbial flocculant produced by Acinetobacter lophi FL-2 on paint mist wastewater.

[0083] 1. Preparation of simulated paint mist wastewater

[0084] Take a daily plastic beverage bottle, add 100mL of tap water, adjust the pH to 12 with 1mol / L NaOH solution, then drip 6 drops of paint with a straw, shake vigorously, and the simulated paint mist wastewater is obtained.

[0085] 2. Preparation of microbial flocculant solution and auxiliary cation solution

[0086] As described in Example 2, the fermentation broth of the present invention cultured on a shaker at 160 r / min at 30° C. for 72 hours was prepared, which was directly used as a medicament for the flocculation test.

[0087] In addition, prepare 1% Na + 、K + , Mg 2+ , Ca 2+ 、Cu 2+ , Fe 3+ , Al 3+ NaCl, KCl, MgSO 4 , CaCl 2 , CuCl 2 , FeCl 3 、Al 2 (SO 4 ) 3 solution as an auxiliary cation solution.

[0088] 3. Experimental design and results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com