Pyrotechnic composition mixing mechanism

A technology of pyrotechnic powder and mixing cylinder, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve the problem that the mixing quality or efficiency of pyrotechnic powder cannot meet actual needs, and achieves the effect of taking into account the mixing efficiency and mixing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

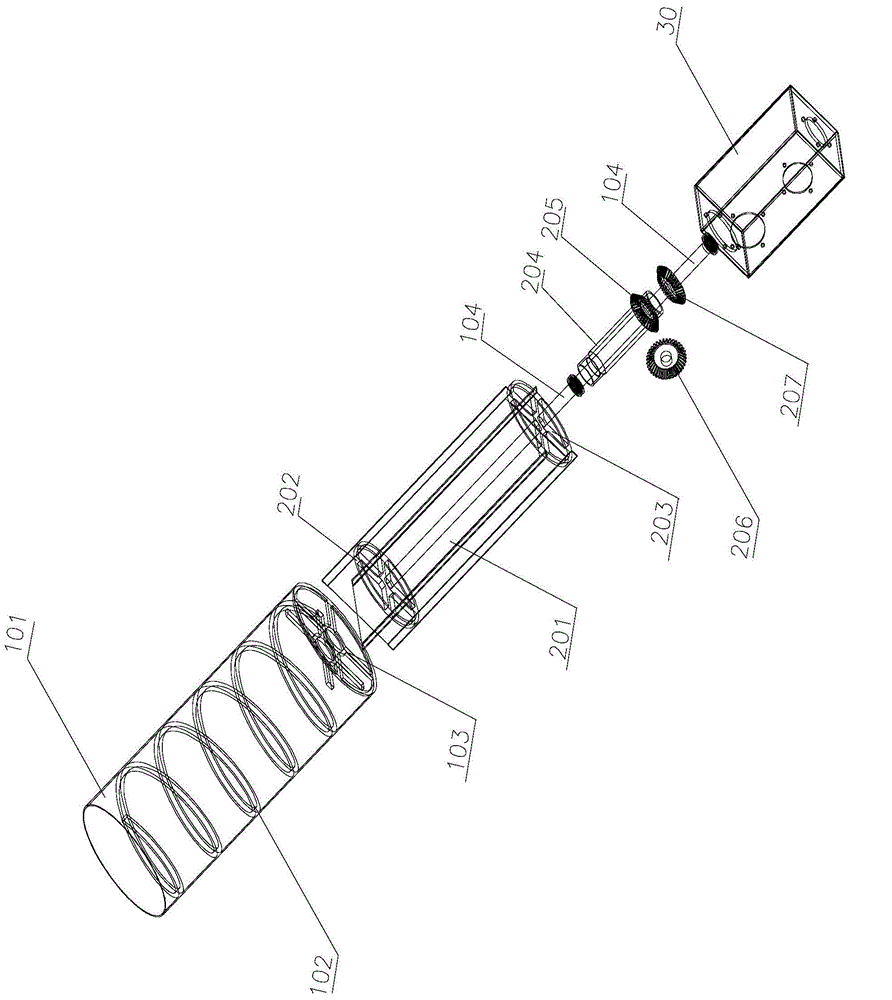

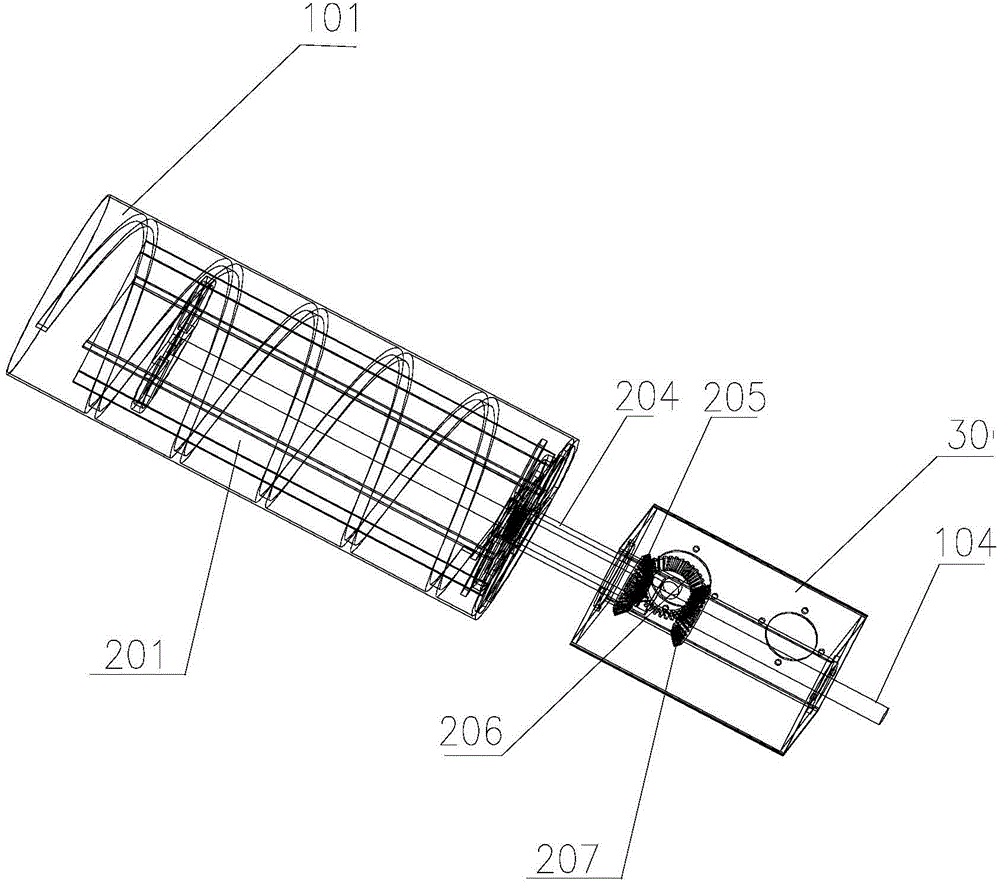

[0018] Referring to accompanying drawing, reflect a kind of specific structure of the present invention, the mixing mechanism of described pyrotechnic powder comprises the mixing cylinder 101 of tilting device, and described mixing cylinder 101 high end is provided with feed inlet, and low end is provided with discharge port, and mixing cylinder 101 101 is connected to the driving device and rotates with the central axis of the cylinder; the inner cavity of the mixing cylinder 101 is provided with a screen mechanism composed of four screen pieces 201 crossed and intersected, and the screen pieces 201 divide the cylinder cavity along the axial direction of the cylinder: sieve The length direction of the mesh pieces 201 is distributed along the axial direction of the mixing cylinder 101, the width direction of the screen pieces 201 is distributed along the radial direction of the mixing cylinder 101, and one side of the length direction of each screen piece 201 is fixed to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com