System and method for monitoring perpendicularity of tower crane

A monitoring system, verticality technology, applied in the direction of cranes, load hanging components, transportation and packaging, etc., can solve the problems of verticality error, manufacturing and installation error, etc., to achieve convenient operation, prevent tipping accidents, good promotion and application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

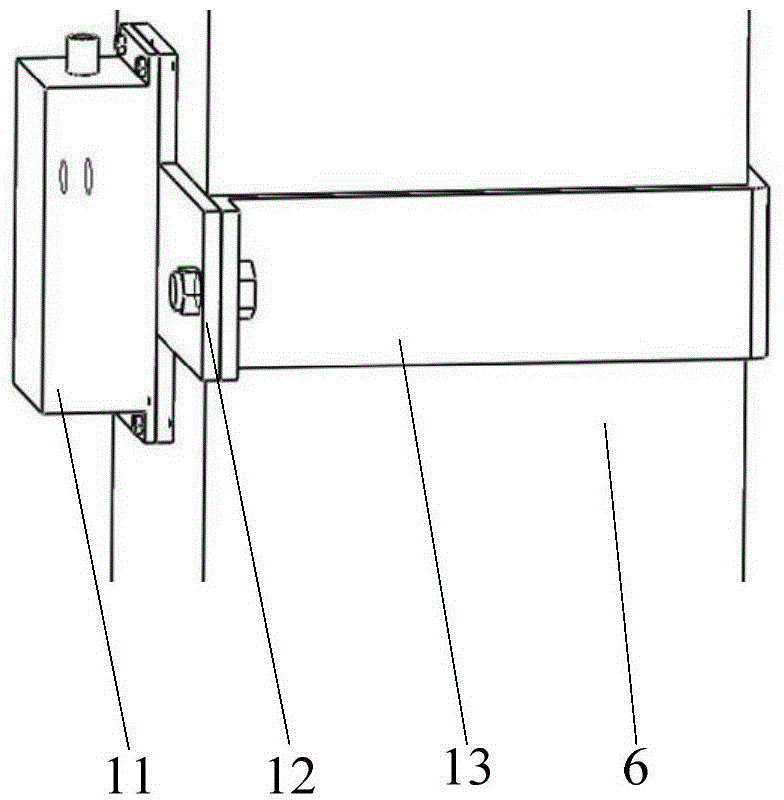

[0021] Such as figure 1 As shown, a tower crane verticality monitoring system includes an inclination measuring device 1 installed on the slewing tower body 6;

[0022] The rotation angle measuring device 2 installed on the upper support 9 of the tower crane; the display alarm device 3 installed on the operation panel in the driver's cab 10 . The inclination measuring device is composed of an inclination sensor 11 , a cross fixing plate 12 and a fixing frame 13 . The inclination sensor 11 is fixed on the cross fixing plate 12 by 4 screws, and the cross fixing plate 12 and the fixing frame 13 are fixed on a main chord of the tower crane slewing tower body 6 by using 2 bolts and nuts. At this time, the contact surface of the inclination sensor 11 and the cross fixing plate 12 should be perpendicular to the measuring surface, and the inclination sensor 11 is fixed on the uppermost end of a main chord of the slewing tower body 6 (generally in the height plane of the root hinge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com