a loading and unloading vehicle

A technology of loading and unloading trucks and bottom plates, which is applied in the directions of loading/unloading, transportation and packaging, etc. It can solve the problems of easy trampled goods, low work efficiency, loss, etc., and achieve the effects of reduced labor intensity, improved efficiency, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

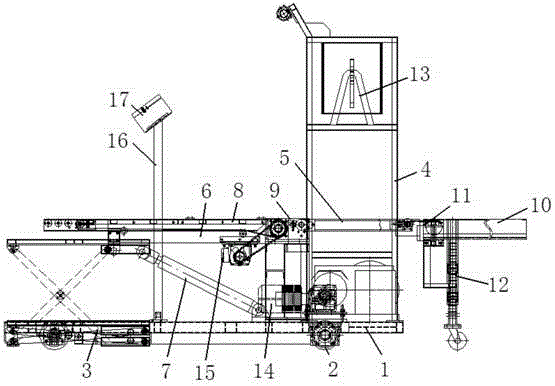

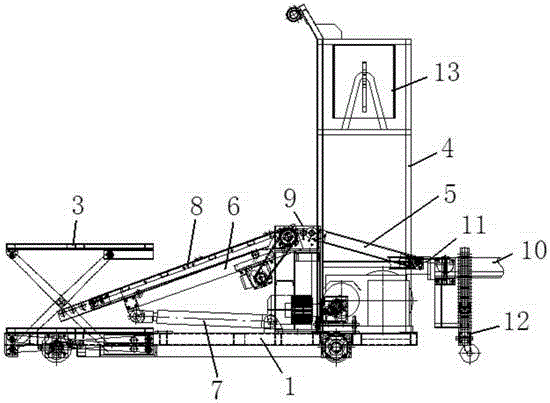

[0025] See attached picture:

[0026] The loading and unloading truck includes a bottom plate 1, wheels 2 are installed on the lower end of the bottom plate 1, and a lifting platform 3 is provided on the left side of the bottom plate 1; a support frame 4 is installed on the right side of the upper end of the bottom plate 1, and a short conveyor belt conveyor 5 is provided in the middle of the support frame 4 , the driving roller at the left end of the short belt conveyor 5 is rotatably installed on the support frame 4, the driven roller at the right end is suspended, the left side of the short belt conveyor 5 is provided with a supporting plate 6, and the right end of the supporting plate 6 is rotatably installed on the supporting frame 4 Above, the left end of the lower end surface of the pallet 6 and the bottom plate 1 are hingedly installed with the piston rod and the base of the lifting cylinder 7 respectively, and a long belt conveyor 8 is installed above the pallet 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com