Wind structure of automobile skylight

A technology for sunroofs and vehicles is applied in the field of windshield structures of vehicle sunroofs, which can solve the problems of increasing the overall cost, increasing the manufacturing cost, and being prone to failures, so as to reduce the frequency of failures, reduce the overall cost, and improve the height of the windshield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further understand the characteristics, characteristics and technical content of the present invention, please refer to the following detailed description and drawings related to the present invention, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

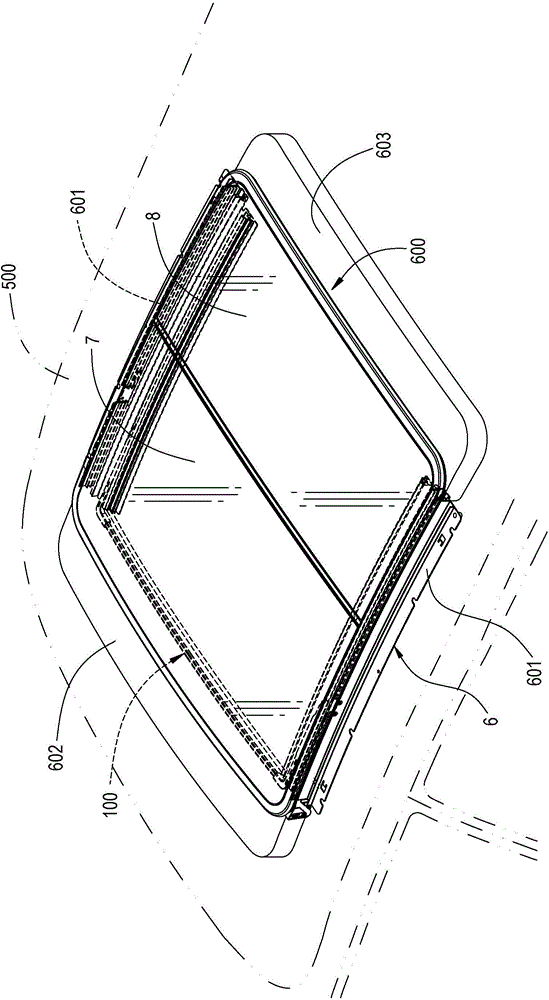

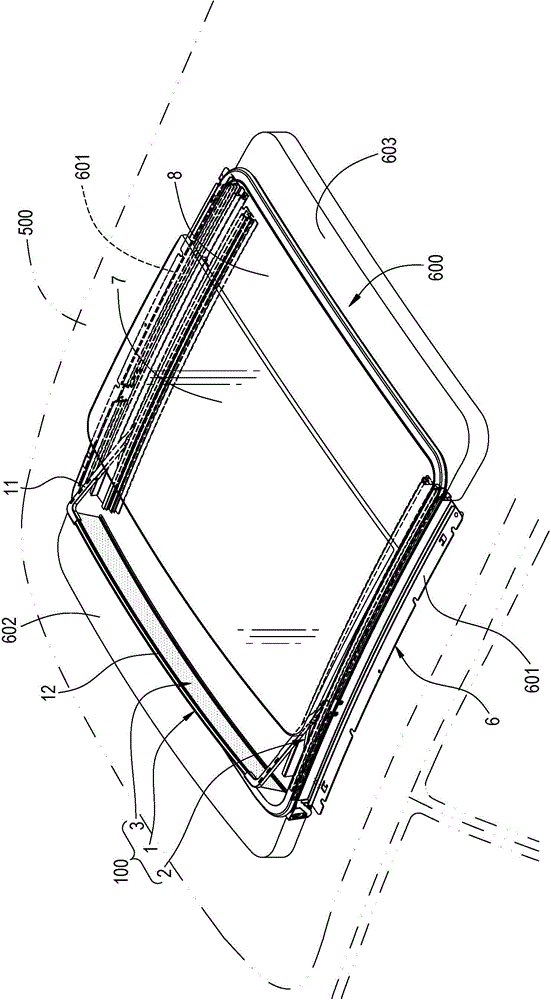

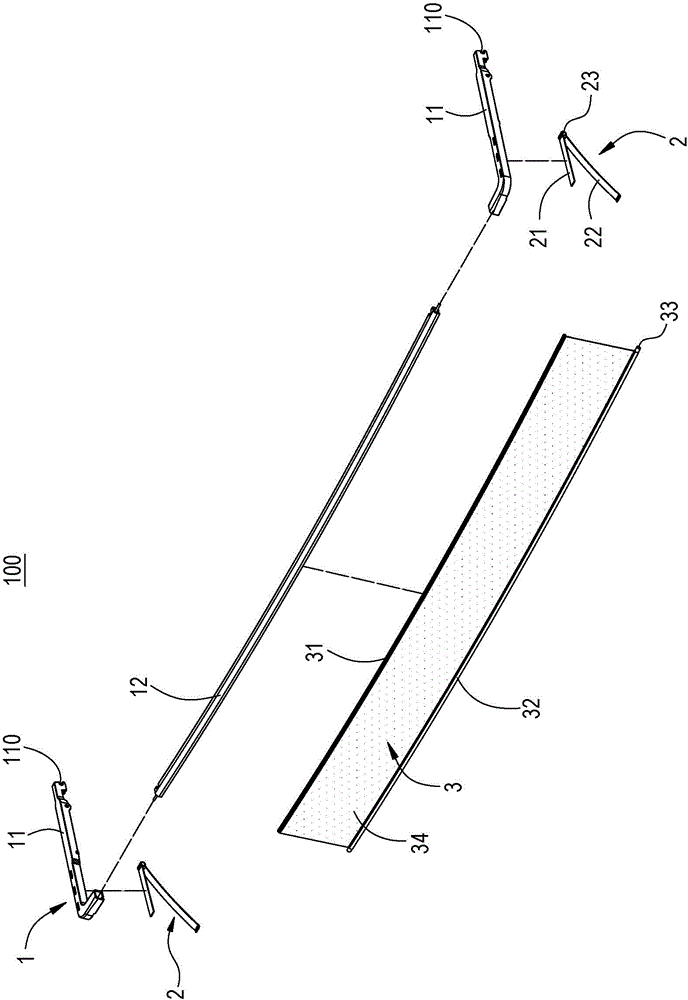

[0070] The invention provides a windshield structure for a sunroof for a vehicle, such as figure 2As shown, in order to be used in the vehicle sunroof 600, the vehicle sunroof 600 is mounted on the roof 500 of the vehicle, and the vehicle sunroof 600 includes a frame 6 (including two side frames 601, connected to the two side frames 601) provided on the roof 500. The front connecting block 602 between one end and the rear connecting block 603 connected between the other ends of the two side frames 601) and the moving mechanism (not marked) provided in the frame 6, a movable glass can be installed in the frame 6 to form A traditional single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com