Systems for the manufacture of cavities

A product and cavity technology, which is applied in the field of systems for manufacturing products with a cavity, can solve the difficulties in processing, installation, disassembly and maintenance, increase the difficulty of mandrel stability and precise positioning, and the length of the mandrel and mandrel is long, etc. problem, to achieve the effect of simple and reliable adjustment method, uniform and accurate wall thickness, and guaranteed rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

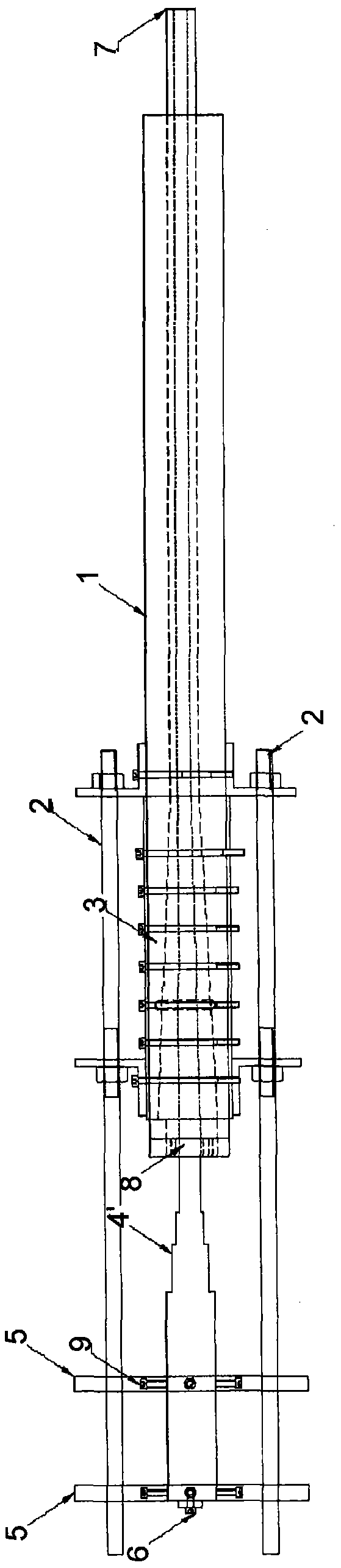

[0038] figure 2 is a side view of the first preferred embodiment of the system for manufacturing cavity products of the present invention. Except for the shape of the mandrel, the basic structure of this embodiment is the same as figure 1 Much the same as shown. Such as figure 2 As shown, the system starts from figure 2Starting from the left side, there are a mandrel fixing and adjusting device 5 , a stepped mandrel 4 ′, a fiber impregnation system 3 and a mold 1 . In this embodiment, the fiber impregnation system 3 can be a low-pressure injection box, and the inlet pressure of the injected resin is 0.001-0.1 MPa. Alternatively, the fiber impregnation system 3 can also be a high-pressure injection box, and the inlet pressure of the injected resin is 0.1-15 MPa. The mandrel fixing and adjusting device 5 , the injection box and the mold 1 are each firmly connected to the mold base 2 by at least one fastener, wherein the mandrel fixing and adjusting device 5 is movable al...

no. 2 example

[0043] image 3 is a side view of the second preferred embodiment of the system for manufacturing cavity products of the present invention. Except for the shape of the mandrel, the basic structure of this embodiment is the same as figure 1 and 2 Much the same as shown. Such as image 3 As shown, the system starts from image 3 Arbor fixing and adjusting device 5, tapered mandrel 4", fiber impregnation system 3 and mold 1 are arranged from the left side of the . In this embodiment, fiber impregnation system 3 can be a low-pressure injection box, and the inlet of the injected resin The pressure is 0.001~0.1MPa. Or, the fiber impregnation system 3 can also be a high-pressure injection box, and the inlet pressure of the injected resin is 0.1~15MPa. The mandrel fixing and adjusting device 5, the injection box and the mold 1 are each fastened by at least one The parts are firmly connected to the formwork 2, wherein the mandrel fixing and adjusting device 5 is movable along the ...

no. 3 example

[0048] Figure 4 is a top view of the third preferred embodiment of the system for manufacturing cavity products of the present invention. Except for the shape of the mandrel, the basic structure of this embodiment is the same as Figures 1 to 3 Much the same as shown. Such as Figure 4 shown, from Figure 4 From the left side, the mandrel fixing and adjusting device 5 , variable cross-section mandrel group 40 , fiber impregnation system 3 and mold 1 are arranged. In this embodiment, the fiber impregnation system 3 can be a low-pressure injection box, and the inlet pressure of the injected resin is 0.001-0.1 MPa. Alternatively, the fiber impregnation system 3 can also be a high-pressure injection box, and the inlet pressure of the injected resin is 0.1-15 MPa. The mandrel fixing and adjusting device 5 , the injection box and the mold 1 are each firmly connected to the mold base 2 by at least one fastener, wherein the mandrel fixing and adjusting device 5 is movable along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com