An automatic device for adding a lining to a fiber bag and a method

A technology of automatic equipment and fiber bags, applied in the field of automation equipment, can solve the problems of low production efficiency, difficulty in satisfying mass production, high process cost, etc., and achieve the effect of improving production and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

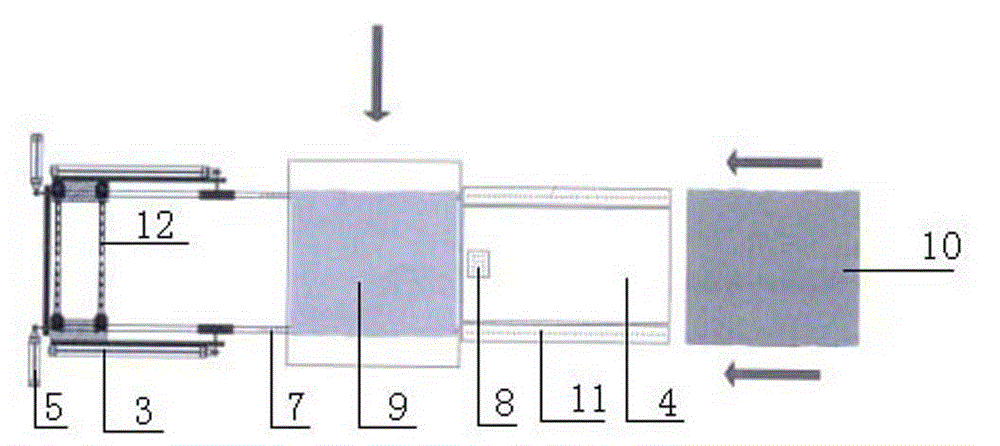

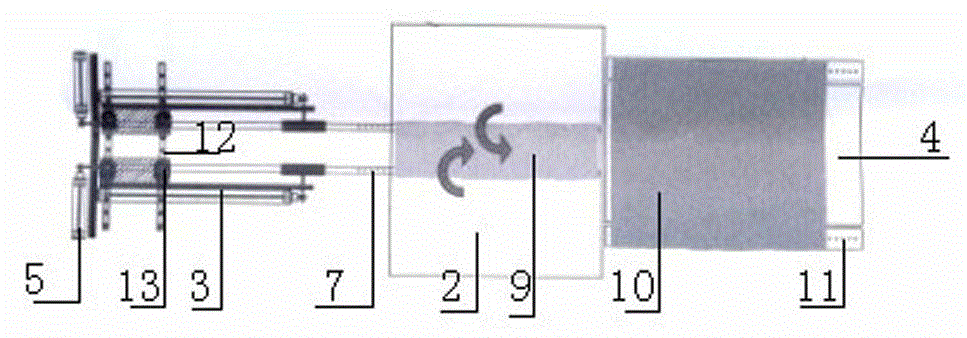

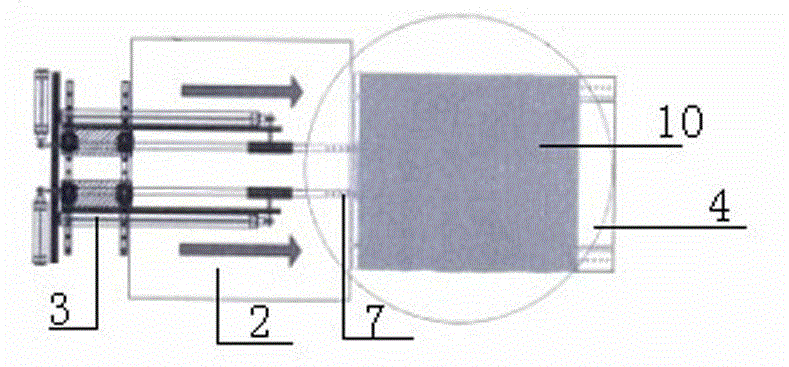

[0017] Such as Figure 1-6 as shown, The present invention provides a kind of automatic equipment and method for adding liner for fiber bag, described equipment: comprise automatic movement system 1, liner table 2, frame 3, vacuum suction workbench 4, wherein automatic movement system 1 is controlled by pneumatic piston The device 5 is driven by the rubber conveyor belt 6, and the pneumatic piston device 5 is connected to the vacuum pump, and the vacuum pump provides its driving power; the inner lining table 2 provides a temporary platform for the inner lining bag 9; the frame 3 is made of stainless steel Two porous vacuum tubes 7 are arranged on the frame 3, and the porous vacuum tubes 7 are connected to a vacuum pump, and the driving power is provided by the vacuum pump; the vacuum suction table 4 is in the same direction as the inner lining table 2, and there is a Air suction system 8, air suction system 8 is connected with vacuum pump, and air suction system 8 draws a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com