Rotary die cutting device

A technology of rotary mold and cutting knife mold, which is applied in metal processing and other directions, can solve the problems of axial back and forth movement, reduce production efficiency, complex assembly process, etc., achieve the effect of preventing axial back and forth movement and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

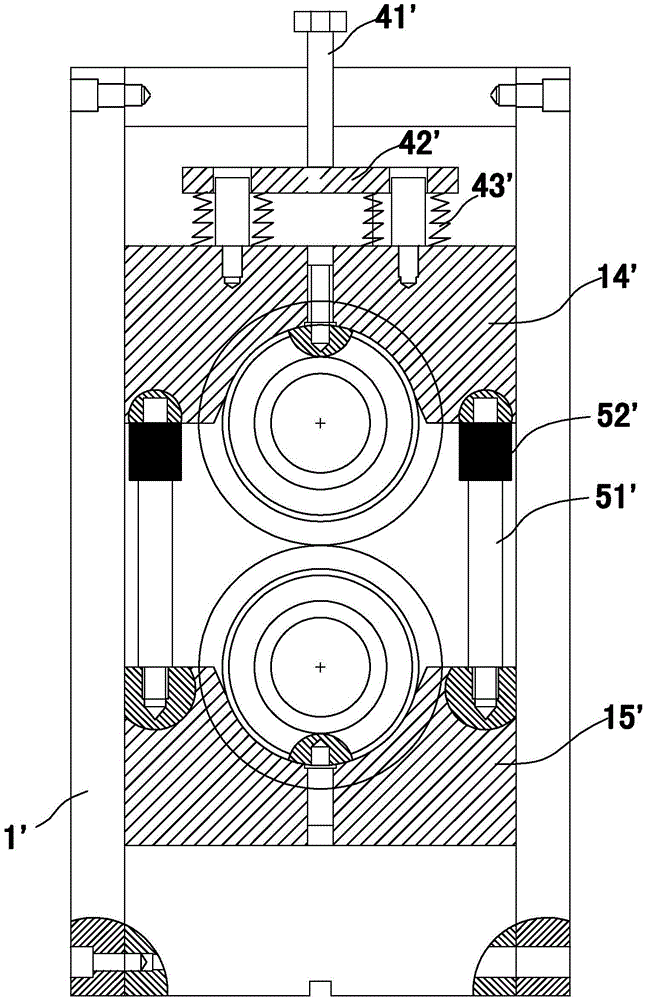

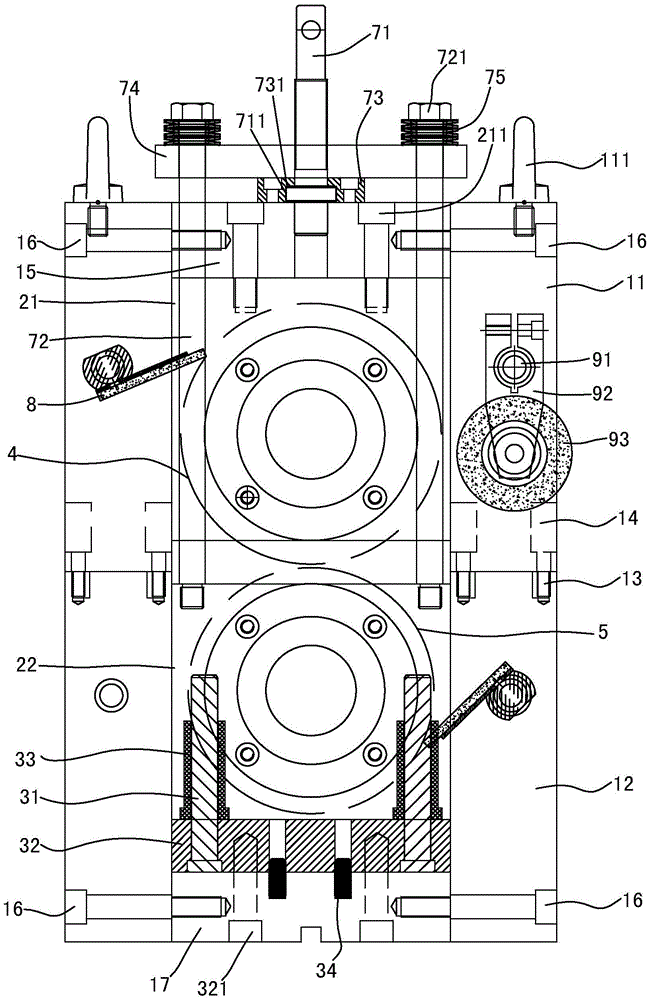

[0024] like Figure 3 to Figure 6, the embodiment of the present invention discloses a rotary die-cutting device, which includes a knife holder, two upper bearing seats 21 and two lower bearing seats 22, and the knife holder includes two upper inverted U-shaped frames 11 arranged at intervals and two lower bearing seats arranged at intervals. U-shaped frames 12, each of the inverted U-shaped frames 11 is respectively arranged on the top of each lower U-shaped frame 12, and the two are connected by bolt locking. 12. The specific connection method is: four threaded holes 13 are correspondingly provided around the upper surface of the U-shaped pins of each lower U-shaped frame 12, and four threaded holes 13 are respectively arranged around the upper surface of the U-shaped pins of each upper inverted U-shaped frame 11. The positions corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com