A spray cap press head suitable for powder content

A content and powder technology, which is applied in the field of spraying caps and pressing heads, can solve the problems that the powder content cannot be sprayed and affects the use effect, etc., and achieve better spraying effect, large spraying pressure and rotating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

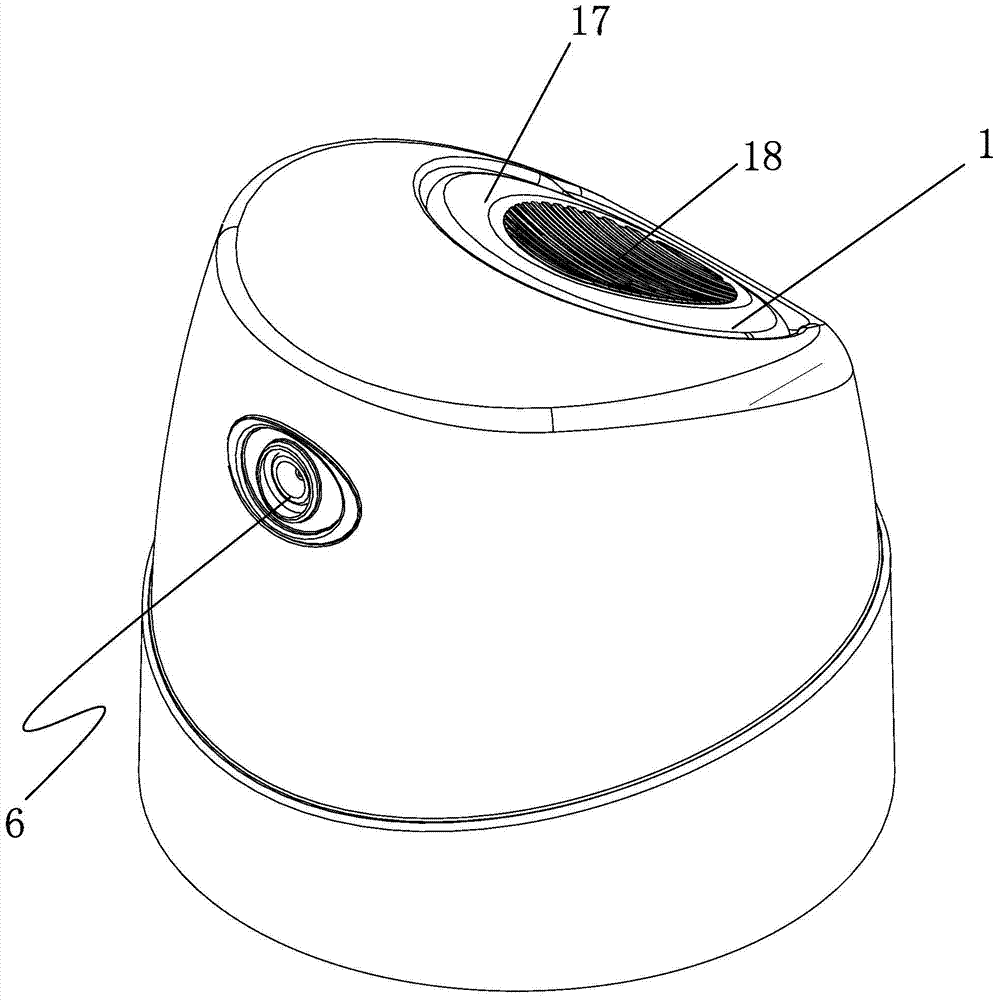

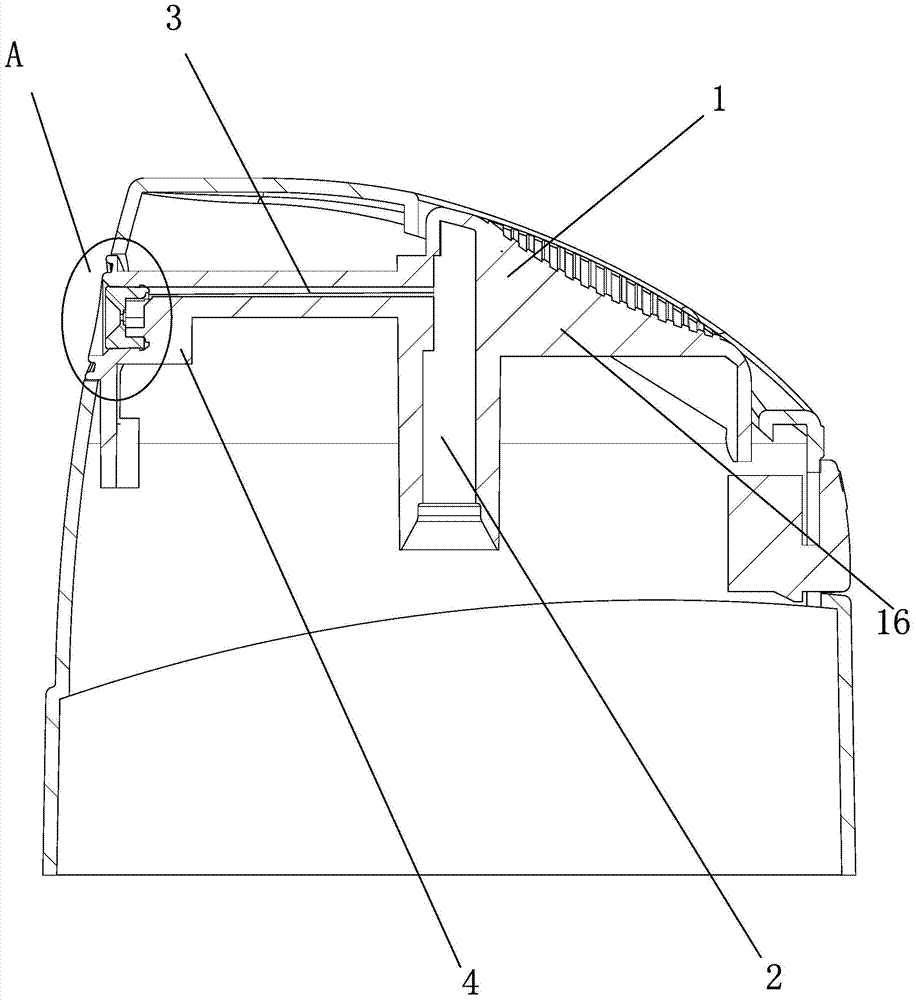

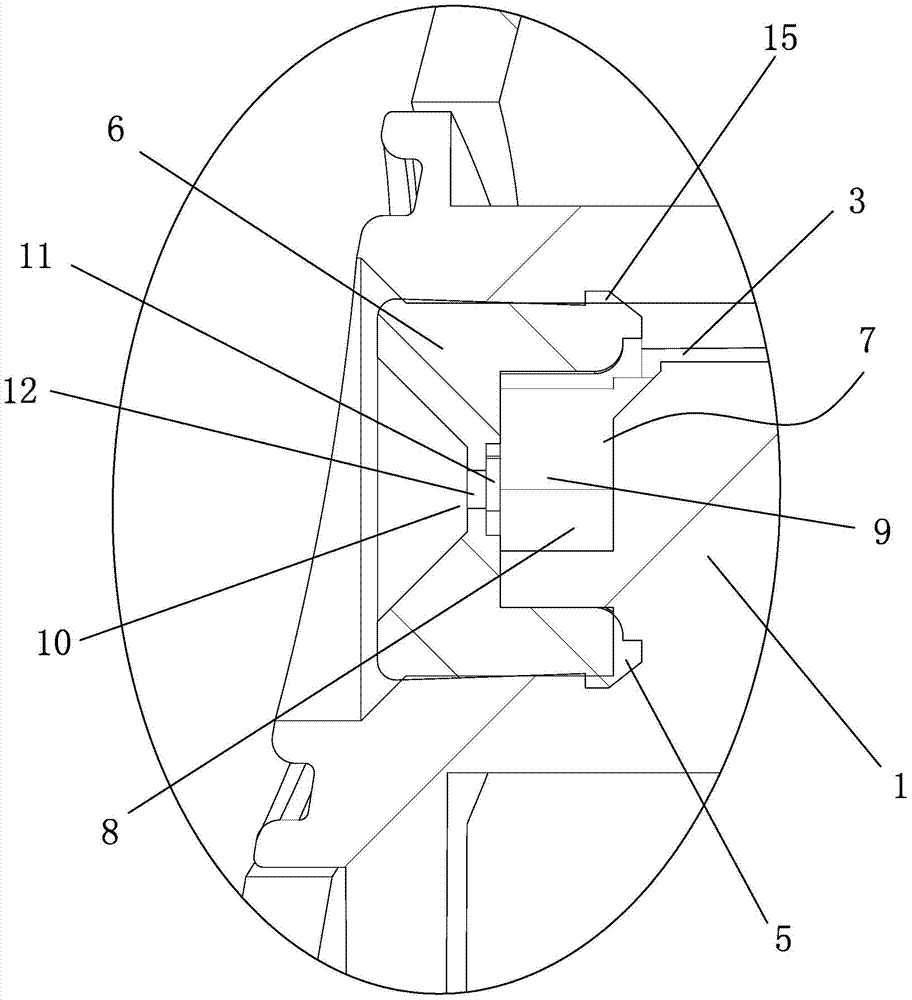

[0024] Such as Figures 1 to 6 The illustrated spray cap press head suitable for powder-type content includes a press head seat 1, a liquid inlet channel 2 is provided under the press head seat 1, and a liquid inlet channel 2 is provided on the press head seat 1. The liquid outlet channel 3 connected with the liquid inlet channel 2 is provided with a connecting part 4 at the front end of the liquid outlet channel 3, and a connecting slot 5 is arranged in the connecting part 4, and the connecting slot 5 and the The liquid outlet channel 3 is connected, and a nozzle mist point 6 is provided in the connecting slot 5, and a nozzle mist point 6 is provided between the nozzle mist point 6 and the bottom of the connecting slot 5 to enable the powder content to flow smoothly from the nozzle mist point 6. The buffer structure 7 that is sprayed ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com