Magnetic heat power generation device

A technology of magnetothermal power generation and hard magnetism, which is applied in the direction of thermoelectric devices, generators/motors, and electrical components that utilize thermal changes in magnetic permeability, can solve problems such as unreasonable structures, and achieve improved adjustability and improved assembly Efficiency and structural stability, the effect of changing the accuracy of the dwelling station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

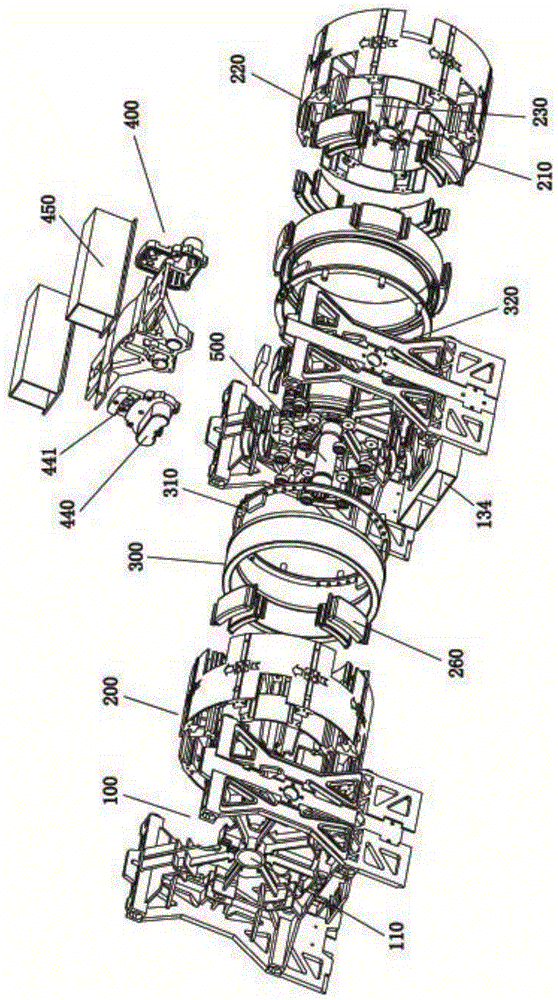

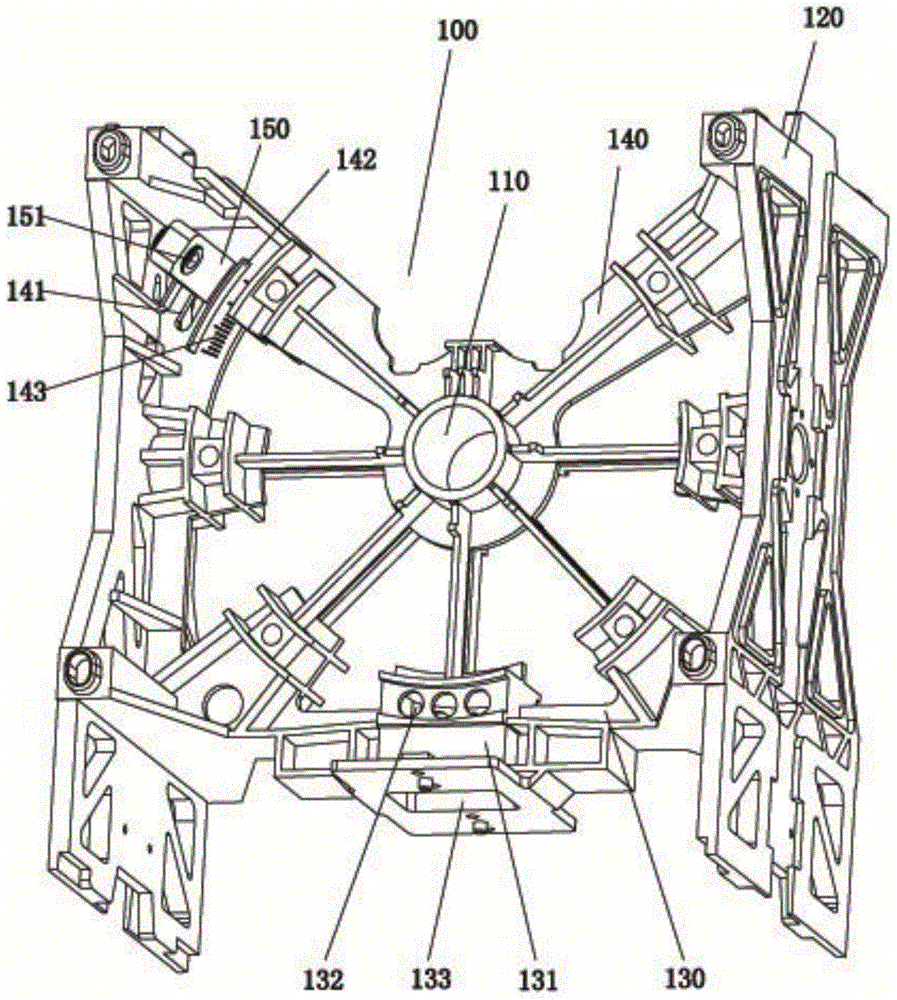

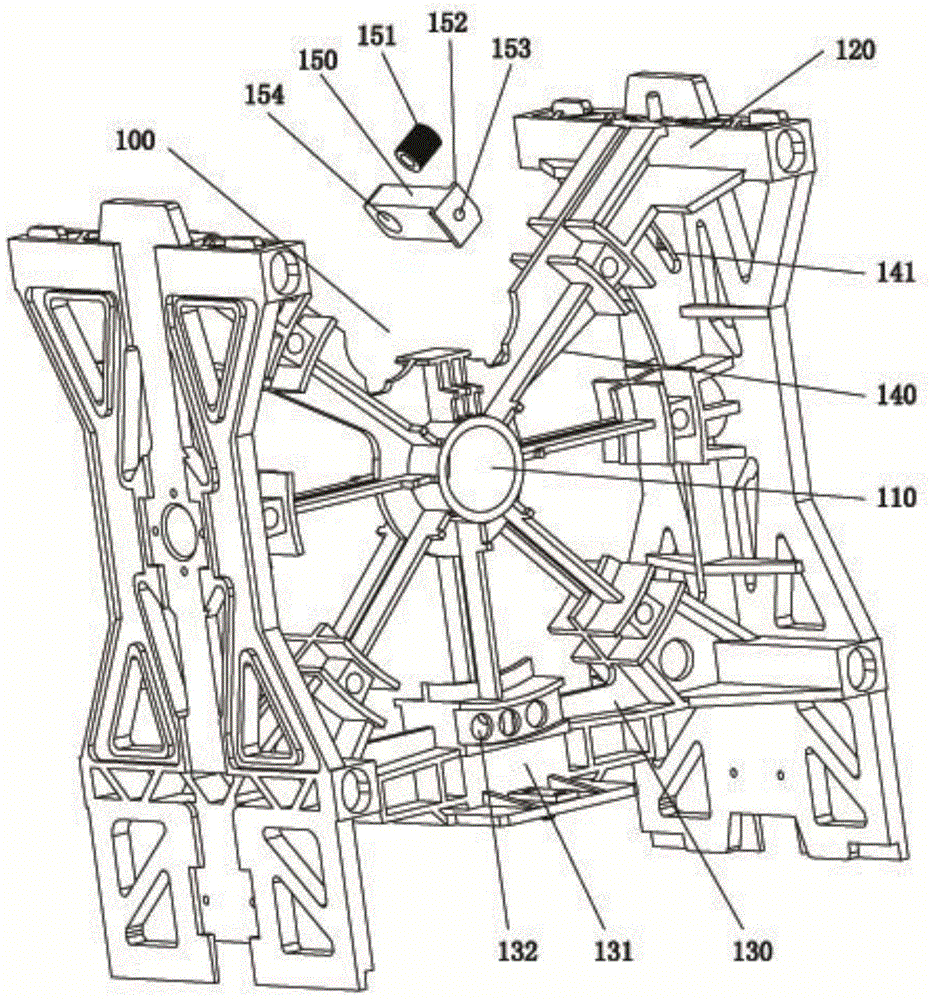

[0031] Such as figure 1 As shown, a magneto-caloric power generation device according to the present invention includes at least one magneto-caloric power generation unit, and the magneto-caloric power generation unit includes two main supports 100, a rotor 200, a stator 300 and a heating and cooling device 400 that are connected and arranged correspondingly. , the main support 100 is provided with a shaft seat A110, and the rotor 200 is provided with a shaft seat B210, an accommodation space is formed between the two main supports 100, the rotor 200 is located in the accommodation space, and the power shaft 500 passes through two The axle seat A110 and the axle seat B210 are arranged so that the rotor 200 is rotatably arranged in the accommodation space, the two stators 300 are fixedly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com