Assembly fixture for motor brush carrier

A technology for assembling tooling and brush assembly, which is used in electromechanical devices, manufacturing motor generators, and electrical components to reduce ablation accidents, improve assembly accuracy, and improve carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

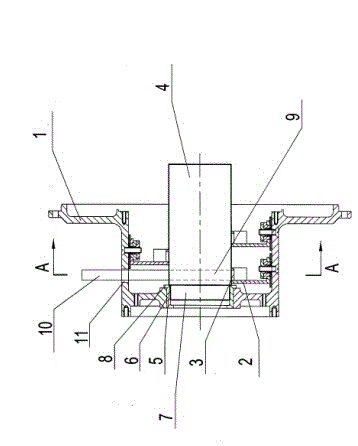

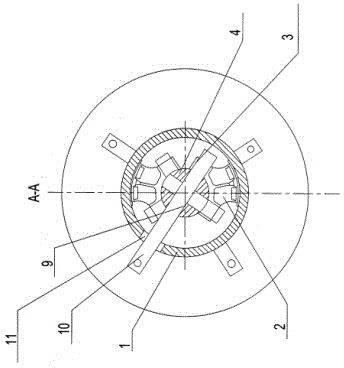

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

[0011] An assembly tool for a motor brush holder, including a motor end cover 1 and a brush holder 2, on which the motor end cover 1 is respectively provided with a relief hole 11 and an end cover bearing chamber 6, and on the brush holder 2 is provided with a brush Assembly hole 3, a cylindrical stepped end shaft 7 is provided at one end of the brush positioning mandrel 4, a through hole 9 is provided on the brush positioning mandrel 4, and the cylindrical stepped end shaft 7 is set in the end cover bearing chamber 6 , the inner spigot end surface 8 on the end cover bearing chamber 6 is connected with the cylindrical step facade 5, and the brush positioning rod 10 passes through the relief hole 11 and the through hole 9 in turn, and then connects with the brush assembly hole 3. Together.

[0012] A plurality of through holes are respectively arranged on the brush positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com