Method for adjusting the critical speed of high-speed combined rotor of micro turbojet engine

A turbojet engine and critical speed technology, which is applied in the direction of engine testing, electric speed/acceleration control, machine/structural component testing, etc., can solve the problem of increasing the space and weight of the aircraft, and not calculating the sensitivity of the combined rotor critical speed , reduce reliability and other issues, to avoid numerical instability, reduce blindness, and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

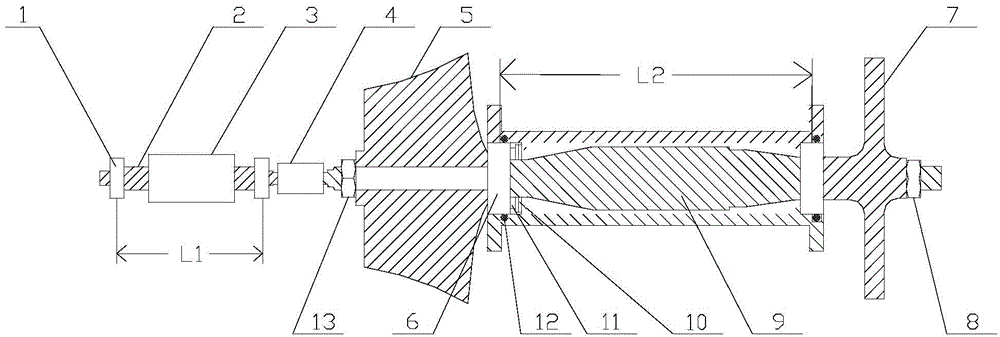

[0031] Such as figure 1 As shown, select a micro-turbojet engine for use in the present embodiment, the rated speed is 106000r / min, and the working speed is 85000r / min-100000r / min.

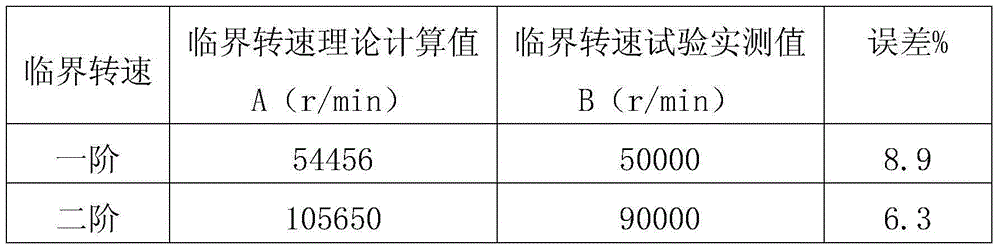

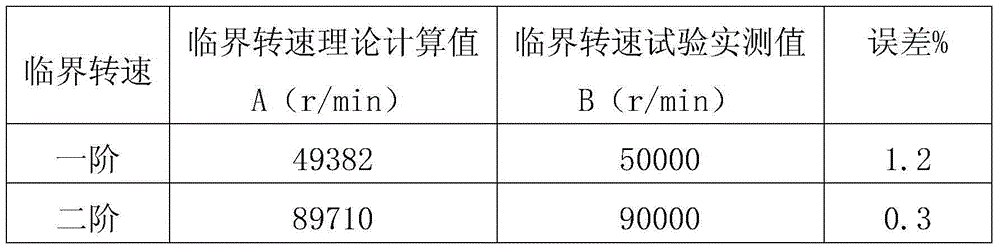

[0032] a. Based on the finite element calculation model, test the critical speed of the combined rotor within the working speed, and define it as the theoretical calculation value of the critical speed A, and define the measured value of the critical speed test of the combined rotor as B; by △=|(A-B) / B|×100% to get the error value △, judge whether the range of the error value △ is 0-5%, if it is, there is no need to adjust the finite element calculation model, if not, it is necessary to correct the finite element calculation model, and finally make the error The value Δ is within 0-5%.

[0033] The calculation results are shown in Table 1:

[0034]

[0035] Table 1

[0036] The difference between the theoretical calculation value A of the critical speed of the rotor critical speed and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com