Control method for textile manufacturing machine

A control method and a technology for manufacturing machines, which are applied to textiles, papermaking, textiles, looms, etc., can solve the problems of being unfavorable to automated production, low production efficiency, and excessive cutting of cloth, so as to facilitate automated production, save cloth, and ensure The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

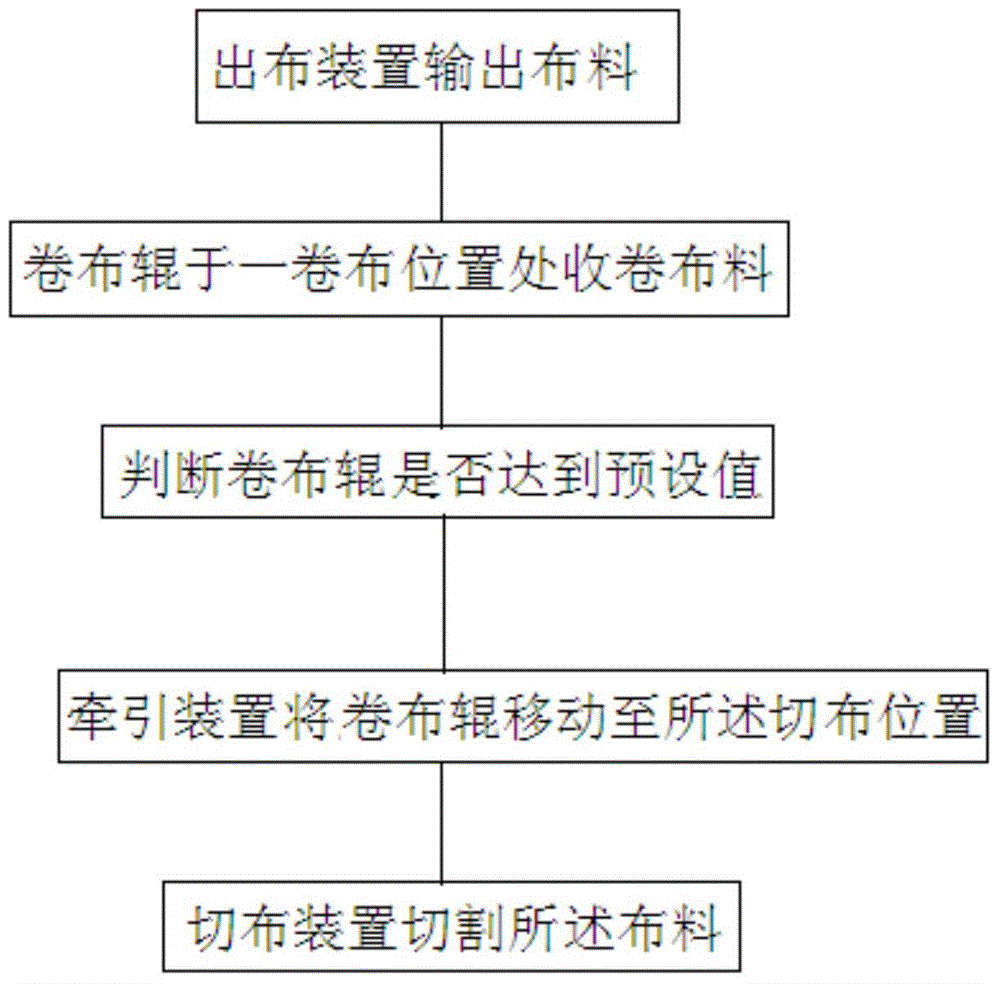

[0034] Such as figure 1 As shown, a control method for a textile manufacturing machine, which includes a cloth discharging device and a cloth winding roller, the cloth discharging device is mechanically connected to the cloth winding roller, and the cloth discharging device is used to output the cloth to the cloth winding roller Cloth, also includes the following steps:

[0035] Step 1, controlling the cloth output device to output the cloth,

[0036] Step 2. Control the cloth rolling roller to wind up the cloth at a cloth position,

[0037] Step 3, judging whether the thickness of the cloth rolling roller reaches the preset value, if it reaches the preset value, execute step 4, if it does not reach the preset value, execute step 2,

[0038] Step 4, controlling a traction device to move the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com