Hydraulic tool car

A hydraulic tool and hydraulic cylinder technology, which is applied in vehicle components, vehicle maintenance, vehicle maintenance/repair, etc., can solve the problems of increasing battery replacement time, motor stall, and no positioning device, etc., and achieves the effect of reliable structure and anti-sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

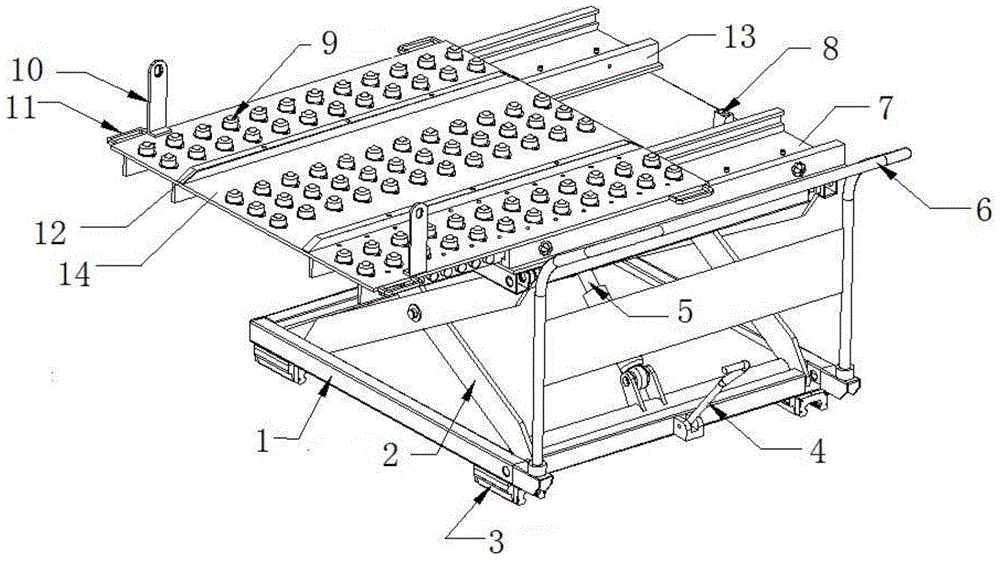

[0035] Embodiment 1: a kind of hydraulic tool cart, its structure is as Figure 1-2 Shown: includes:

[0036] A main frame 1, four traveling sliders 3 are installed at the bottom of the main frame 1, and the traveling sliders 3 can bear relatively large heavy loads and partial loads;

[0037] The lifting plate 7 connected with the main body frame 1 through the lifting mechanism;

[0038] The bearing plate 14 that is slidingly connected with the lifting plate 7 is divided into three sliding areas by the left limiting plate 12 and the right limiting plate 19, any sliding area is provided with universal balls 9, located at Locking blocks 10 are respectively arranged on the sliding areas on both sides, and the locking blocks 10 have locking holes. When replacing the battery, spring telescopic rods extend out from both sides of the battery box and insert them into the locking holes to lock and fix the battery box so that the battery box is not easy to slide on the universal ball....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com