An automatic nail-piercing device compatible with 1-4 pole circuit breakers

A circuit breaker and automatic threading technology, which is applied in the field of automatic assembly, can solve problems such as unqualified product quality, increased production costs, and low production efficiency, and achieve the effects of improving speed and efficiency, increasing working speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

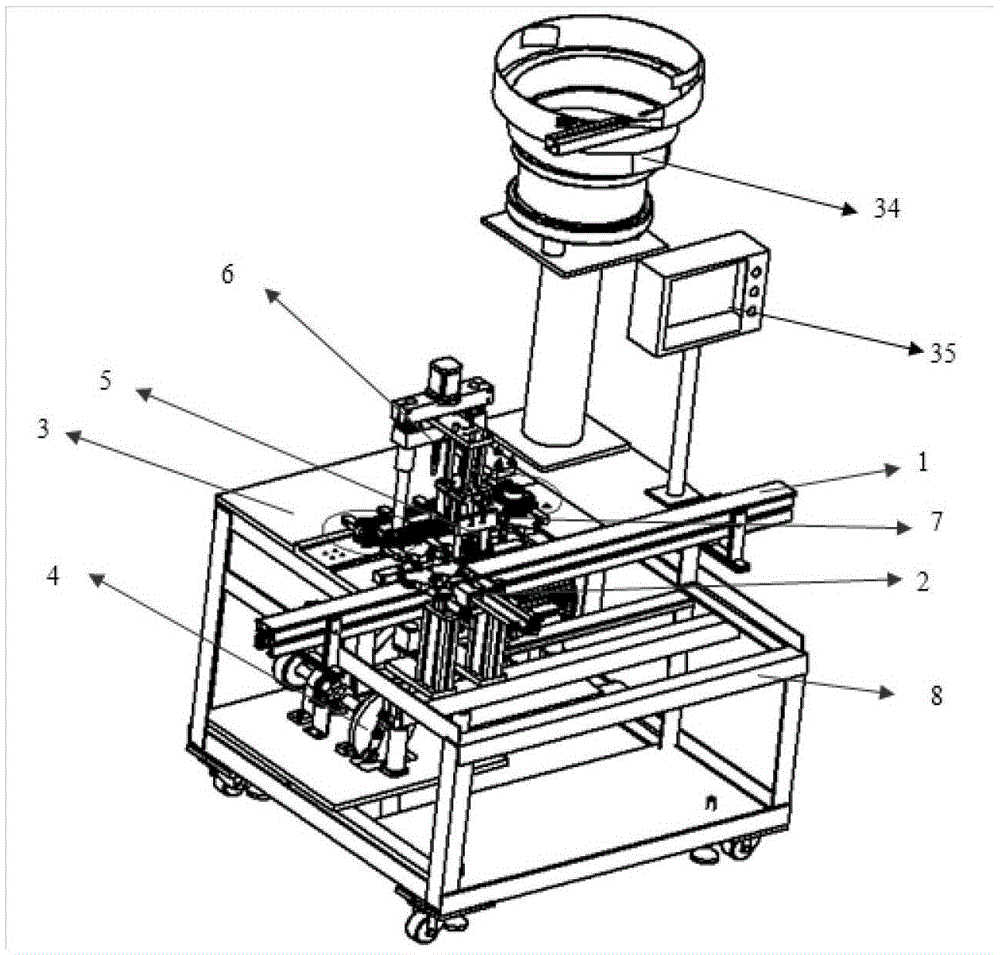

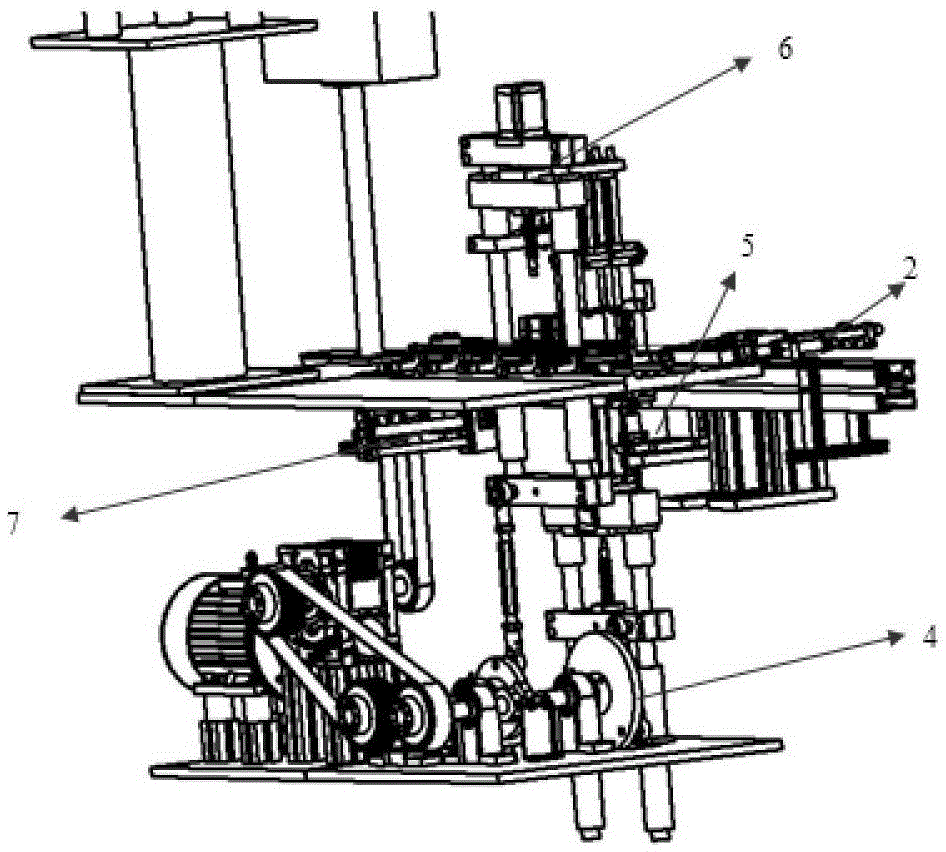

[0034] Such as Figure 1-8 As shown, the present invention provides an automatic nail-piercing device compatible with a 1-4 pole circuit breaker, which includes a conveyor belt 1, a feeding mechanism 2, a table top mechanism 3, a nail-piercing guide mechanism 4, a nail falling mechanism 5, and a nail pressing mechanism 6. Unloading mechanism 7 and frame 8;

[0035] The conveyor belt 1 is used to convey the workpieces to be nailed. The conveyor belt 1 adopts the form of a chain plate assembly line, which is compatible with the production lines of most production enterprises. The front is a manual assembly workbench, and the rear flows to the automatic riveting equipment; the feeding mechanism 2 Set on the side of the conveyor belt 1;

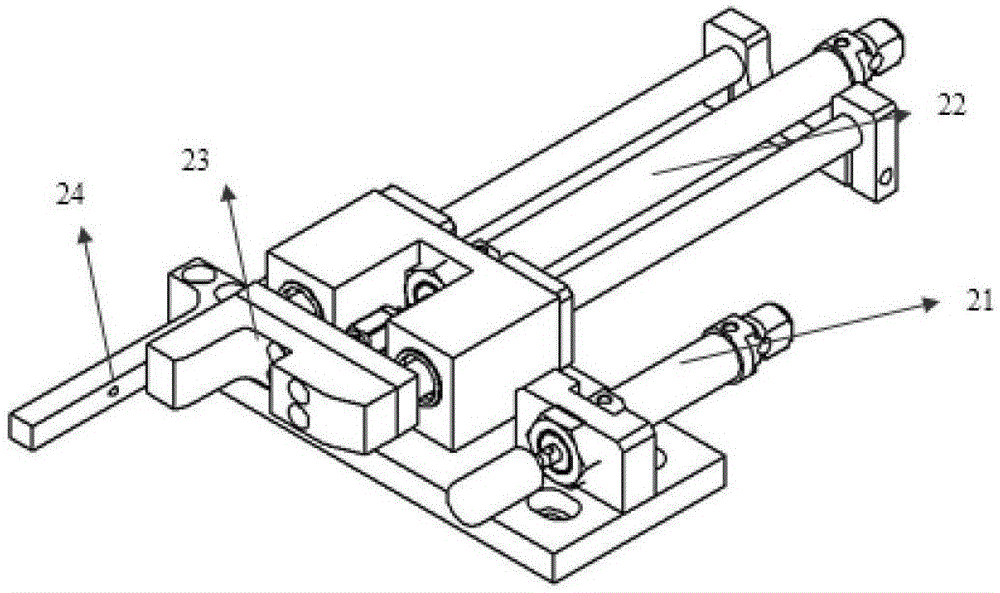

[0036] The feeding mechanism 2 includes a feeding spacer cylinder 21, a feeding feeding cylinder 22, a feeder 23, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com