Filling method for filter material

A filling and filtering technology, which is applied in separation methods, chemical instruments and methods, loose filter material filters, etc., can solve the problems of slow filling speed and easy contamination of the upper end of the central tube in the threaded barrel, and achieve fast filling. , The effect of preventing the filter material from contaminating the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

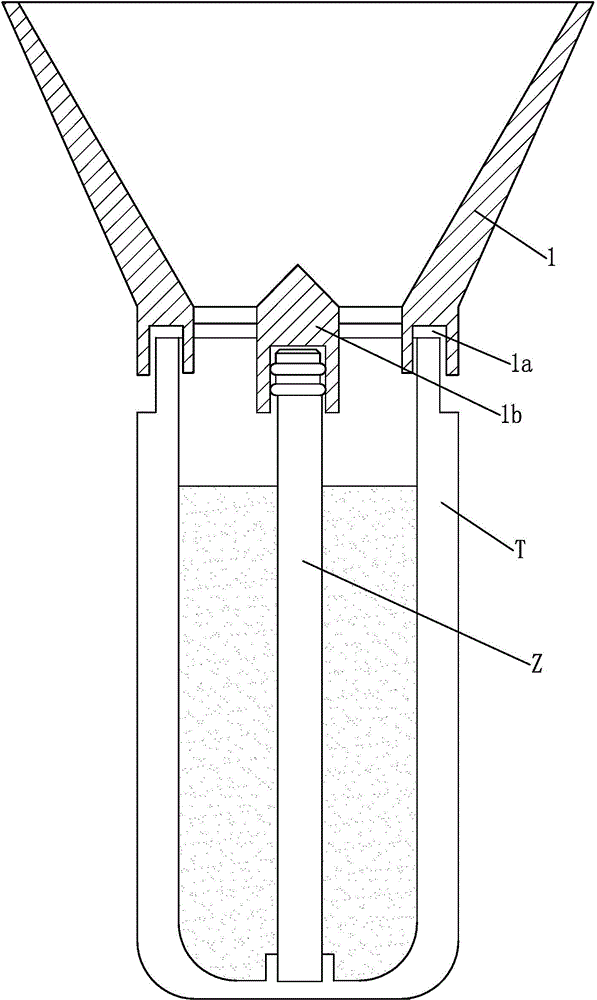

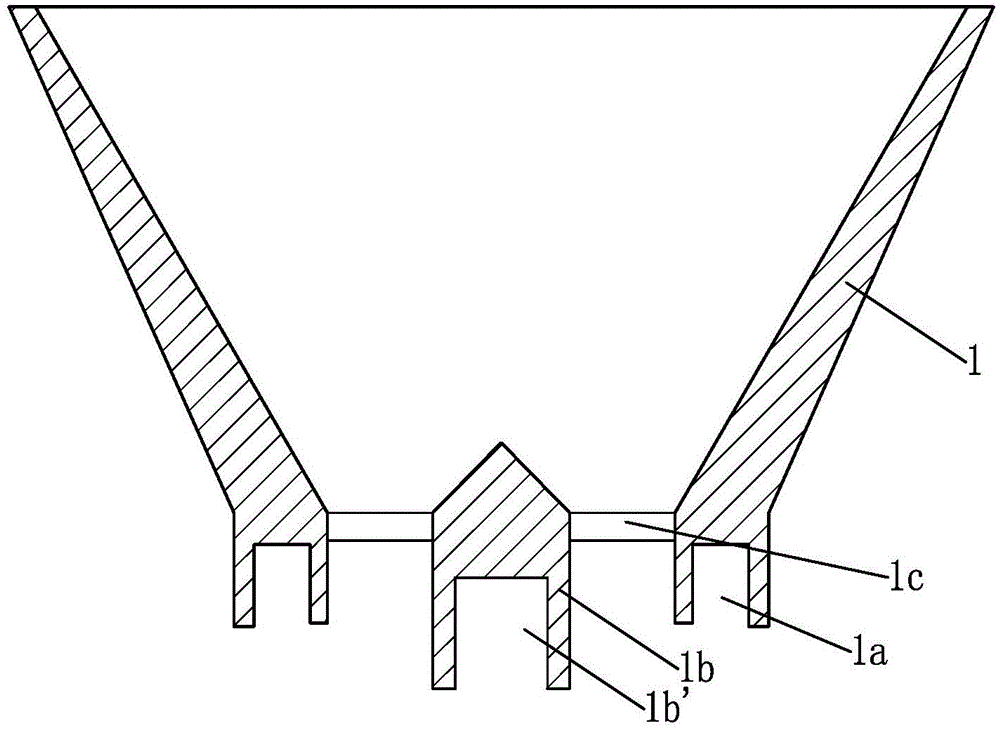

[0018] Such as figure 1 , 2 Shown, a kind of filter material filling method is characterized in that comprising the steps:

[0019] Step a: first place the cylinder T vertically;

[0020] Step b: Select a filler with a suitable size and specification. The body 1 of the filler is a funnel-shaped structure, and the bottom surface of the body 1 is provided with an annular groove 1a. The axis of the annular groove 1a is aligned with the axis of the body 1. Heart lines coincide. Moreover, the depth of the annular groove 1a is 2-5mm, and can be further preferably 3 and 4mm, and the depth dimension should ensure that the filler is firmly supported on the threaded connection at the upper end of the upper cylinder S.

[0021] The center of the body 1 is provided with a protective post 1b, the lower part of which is exposed outside the main body 1, and the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com