Separation and collection system and method for solid pollutants in solid-liquid mixed solution

A solid-liquid mixing and collection system technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems that screen technology cannot be directly applied to sewage treatment and disposal, river dredging projects, and high equipment costs to achieve separation and The collection effect is excellent, the cost is low, and the effect of solving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

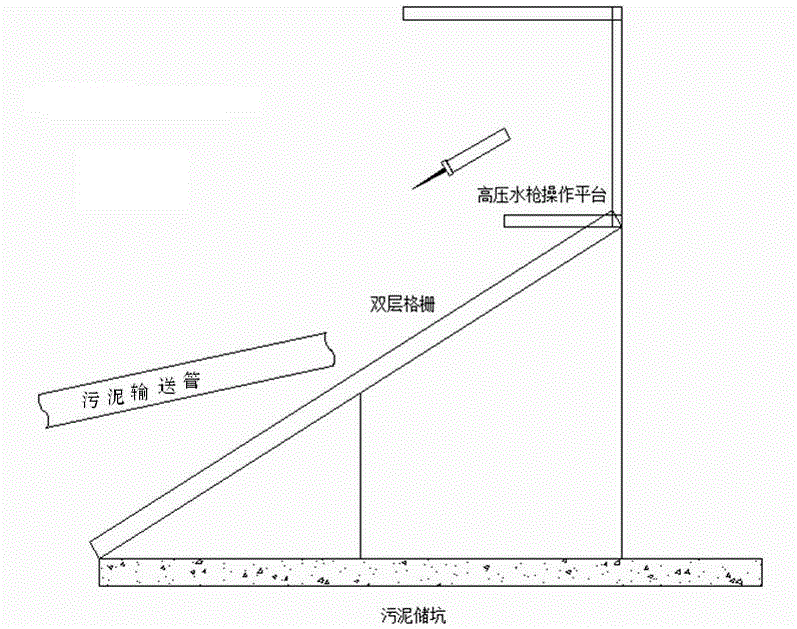

[0038] See figure 1 , a system for separating and collecting solid pollutants in a solid-liquid mixture according to this embodiment, including a screen surface, a mesh surface fixing device, and a sieving garbage collection subsystem. Among them, the mesh surface of the screen adopts a square mesh structure, which is divided into two layers. The upper layer of the screen mainly plays the role of intercepting pollutants, and the lower layer of the screen mainly plays a supporting role; The fixing device is mainly composed of a supporting structure, a fixing slot of the screen mesh, a fixing slot of a high-pressure water gun and a dynamic support. The mesh surface fixing slot fixes the lower screen, the upper screen and the supporting structure are fixed with iron wires, and the inclination angle of the screen surface is freely adjusted through the dynamic support, and the inclination angle for commonly used wastewater filtration is usually selected as 20 o to 30 o The sievi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com