Touch panel and method for manufacturing the same

一种触摸板、基板的技术,应用在数据处理的输入/输出过程、仪器、电数字数据处理等方向,达到改进总体可见性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

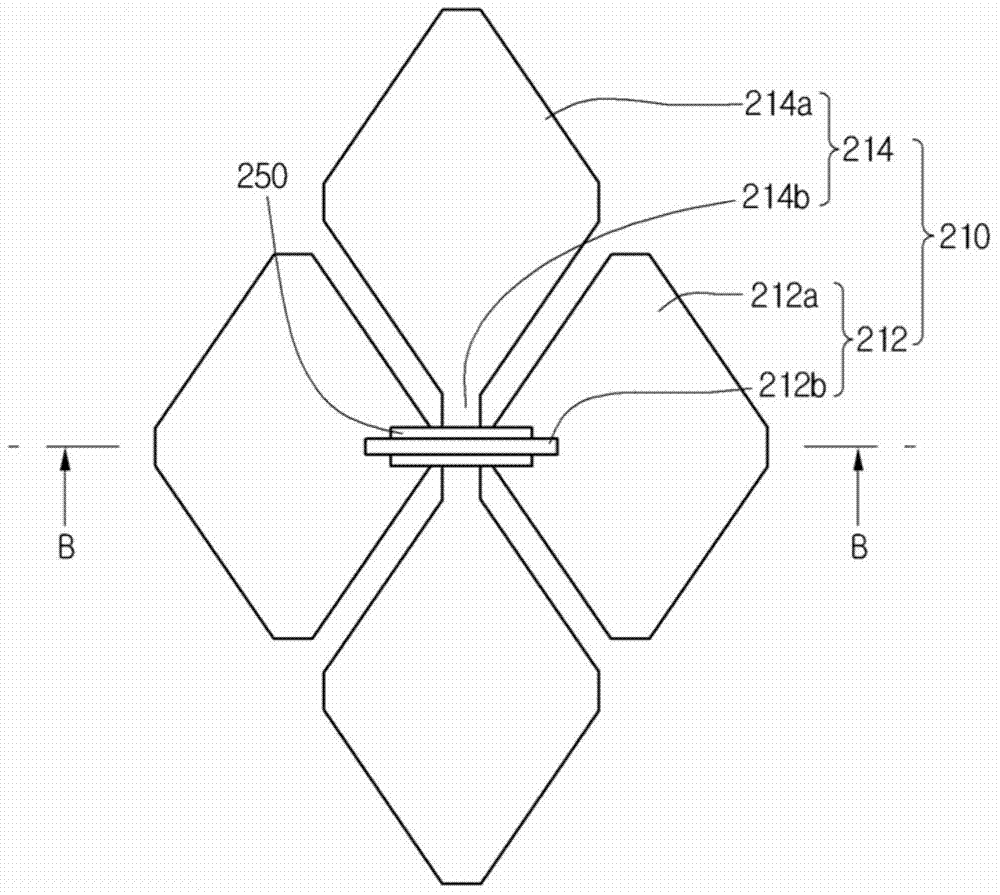

[0058] The sensor portion is formed on a glass substrate by depositing indium tin oxide (ITO). An insulating layer is formed on the sensor part. Molybdenum, argon, nitrogen and carbon dioxide are deposited on the insulating layer by a reactive sputtering process to form a first light absorbing layer. Therefore, the first light absorbing layer includes nitride and oxide. The buffer layer including the first buffer layer, the conductive layer and the second buffer layer is formed by forming a first buffer layer including molybdenum (Mo), a conductive layer including silver (Ag), and a second buffer layer including molybdenum on the first light absorbing layer. Layer connection electrodes.

Embodiment 2

[0060] The touch panel according to the second embodiment was manufactured in the same scheme as in the first embodiment, except that a second light absorbing layer was additionally formed in the same scheme as that of forming the first light absorbing layer on the connection electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com